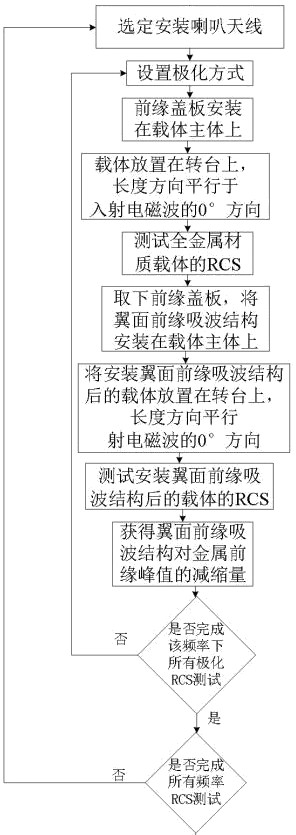

Low-scattering carrier for airfoil front edge wave-absorbing structure RCS test and test method

A technology of wave structure and low scattering, applied in the field of electromagnetic scattering measurement, can solve the problems of difficulty in using low-scattering carriers, shorten the manufacturing cost and cycle, etc., and achieve the effect of eliminating chaotic scattering and reducing the peak value of specular scattering.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

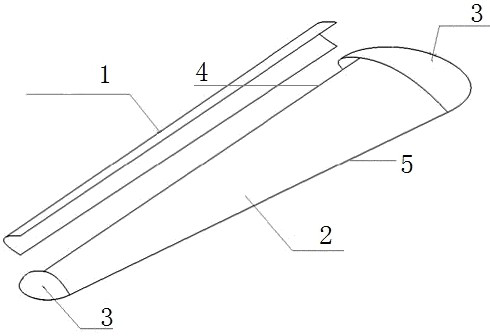

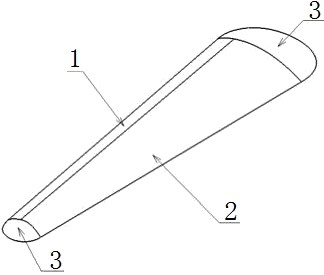

[0046] This embodiment proposes a low-scattering carrier for the RCS test of the leading edge wave-absorbing structure of the airfoil, which is used for the RCS test of the wave-absorbing structure of the airfoil leading edge; figure 2 , image 3 , Figure 4 , Figure 5 As shown, the low-scattering carrier includes a front edge cover plate 1 and a carrier body 2;

[0047] The carrier body 2 is a horizontally arranged flat strip-shaped structure, and the strip-shaped structure of the carrier body 2 is a metal hollow structure with a thick middle of the outer structure and gradually flattened front and rear sides; the thickness direction of the carrier body 2 The section above is in the shape of a water drop with a blunt front and a sharp rear;

[0048] The front edge 4 of the elongated structure of the carrier body 2 is a linear structure that is attached to the front edge wave-absorbing structure of the airfoil, and the curved surface at the junction of the front edge cove...

Embodiment 2

[0053] This embodiment is based on the above-mentioned embodiment 1, in order to better realize the present invention, further, as figure 2 , image 3 As shown, the low-scattering carrier also includes a carrier end face 3; the carrier end face 3 is a flat cover structure in which the upper and lower curved surfaces shrink into a curve; the carrier end face 3 is provided with one large and one small two, respectively. The large and small ends of the flat elongated structure disposed on the carrier main body 2 are detachably corresponding to form a structure that can fix the front edge cover plate 1 on the carrier main body 2 .

[0054] Further, the width of the narrower end of the carrier body 2 is greater than or equal to 3.2 times the signal wavelength corresponding to the lowest frequency tested during the RCS test.

[0055] Further, the length of the low-scattering carrier is smaller than the size of the quiet zone of the test site when the RCS test is performed.

[005...

Embodiment 3

[0060] In this embodiment, on the basis of any one of the above-mentioned embodiments 1-2, the setting principle of each component is further described:

[0061] Such as figure 2 , image 3 As shown, the carrier adopts a metal hollow structure to reduce weight, and the surface roughness is Ra≤1.6. It is composed of a front edge cover plate 1, a carrier body 2, and a carrier end surface 3. The head, and the opposite side is the rear. The shape of the leading edge cover plate 1 is the same as that of the leading edge wave-absorbing structure of the airfoil. Its function is to be installed on the main body of the carrier for testing the RCS of the all-metal carrier. It can be disassembled, and the wave-absorbing structure at the leading edge of the airfoil is installed in situ. The upper and lower curved surfaces of the carrier end surface 3 shrink into a curve, forming a flat shape. The edge diffraction of the curve is used to replace the specular scattering brought by the pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com