Isolation sleeve

A technology of isolating sleeves and sleeve holes, applied in the direction of insulators, contact surface shape/structure, etc., can solve problems such as insufficient electrical insulation performance, difficulty in centering moving contacts and static contacts, etc., and achieve good voltage equalization effect, Conducive to the effect of uniform distribution and uniform wall thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

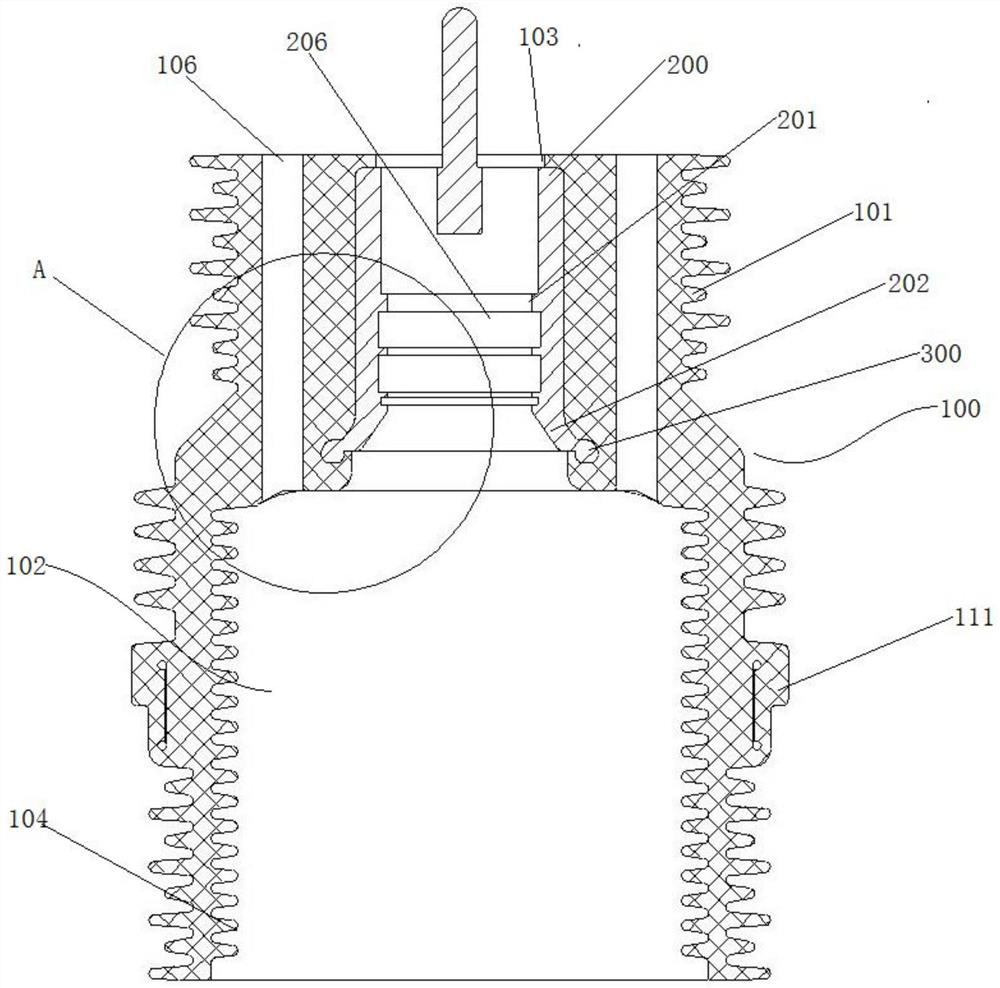

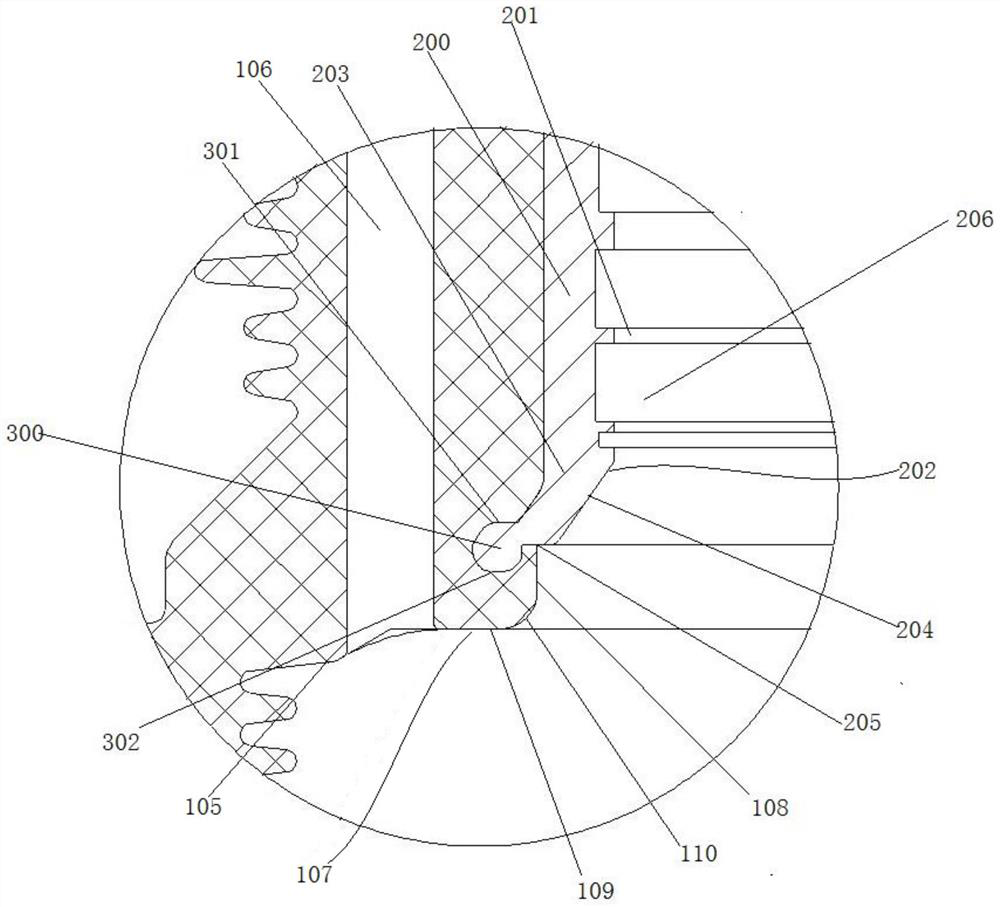

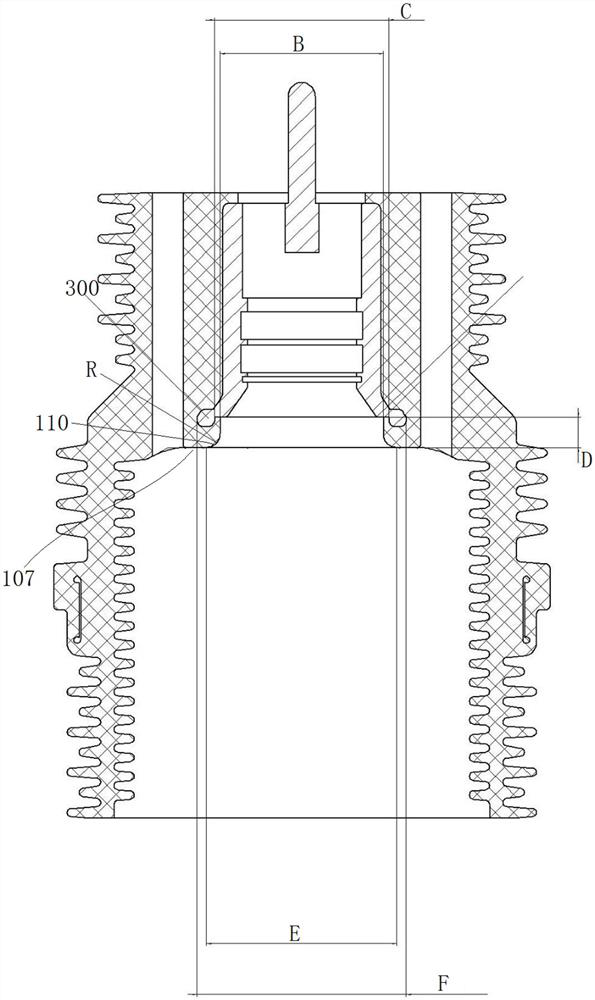

[0044] Such as Figure 1 to Figure 5 As shown, the present embodiment provides an isolating bushing. The isolating bushing includes an insulating casing 100 and a static contact 200. The static contact 200 is arranged in the casing hole 101 of the insulating casing 100. The lower end of the static contact 200 has a horn Shaped turning edge 202 and the outer ring 300 connected at the end of turning edge 202, the outer wall surface of turning edge 202 is an outer tapered surface 203, and the inner wall surface of turning edge 202 includes a tapered section 204 and a horizontal section 205, wherein the tapered section 204 Formed by the hole wall of the tapered hole at the bottom of the socket 201, the hole at the lower end of the tapered hole forms the lower end opening of the socket 201, for when the movable contact 400 is inserted into the static contact 200, the movable contact 400 for alignment.

[0045] Specifically, such as figure 1 and figure 2 As shown, the insulating...

Embodiment 2

[0053] The difference between this embodiment and Embodiment 1 is that in Embodiment 1, the lower end surface of the outer ring is lower than the horizontal section. However, in this embodiment, the lower end surface of the outer ring is flush with the horizontal section.

Embodiment 3

[0055] The difference between this embodiment and Embodiment 1 lies in that in Embodiment 1, the transition between the wall surface of the hole and the end surface of the hole is rounded. In this embodiment, the wall surface of the hole and the end surface of the orifice are perpendicular to each other, and the transition between the wall surface of the hole and the end surface of the orifice is at right angles.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com