Monocrystal FBAR piezoelectric film and preparation method thereof

A piezoelectric film and crystal piezoelectric technology, applied in the direction of electrical components, impedance networks, etc., can solve problems such as damage to single crystal piezoelectric film, damage to single crystal piezoelectric film, and incomplete decomposition of the peeling layer to achieve high-quality factors Good, improve the accuracy, save the effect of the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0087]The present invention also provides a method for preparing a cavity type thin film bulk acoustic resonator, the specific steps are as follows:

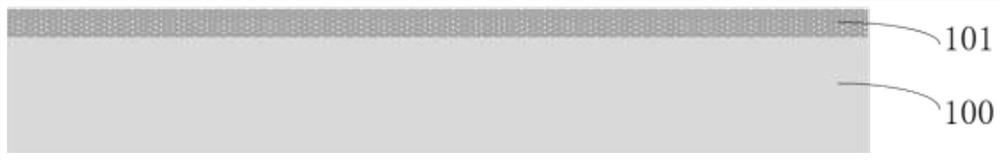

[0088] (1) Cleaning the double-polished sapphire substrate 100, using acetone and isopropanol for ultrasonic washing, and the orientation of the sapphire substrate is C(0001);

[0089] (2) if figure 1 As shown, a GaN film of 1 μm is deposited on the surface of the double-polished sapphire substrate 100 by magnetron sputtering or MOCVD as the lift-off layer 101. The growth process of the GaN film: the TMGa gas flow rate is 20 sccm, the NH 3 The gas flow rate is 800sccm, the growth temperature is 1000°C, the chamber pressure is 30mbar, and the growth rate is about 10nm / min. Sometimes, in order to make the GaN film more compatible with the sapphire substrate, a layer of about 100nm is sputtered before growing the GaN film. ALN film;

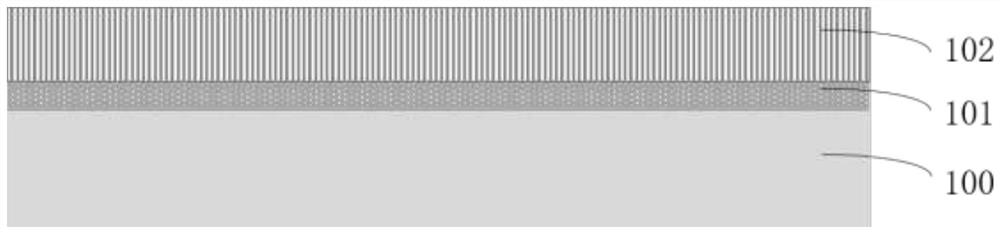

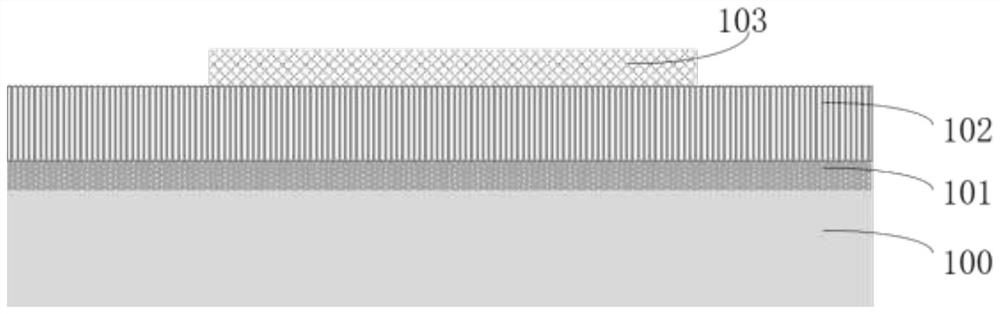

[0090] (3) if figure 2 As shown, a 800nm ALN single crystal piezoelectric film 102 is deposi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com