Optimized ship facilitating pressure discharge of seawater ballast bin

A ballast tank and seawater technology, applied in the field of ship ballast tanks, can solve problems such as increased use costs, poor drainage efficiency, and waste of energy, and achieve the effects of rationalized structural layout and installation, improved water intake efficiency, and improved discharge efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

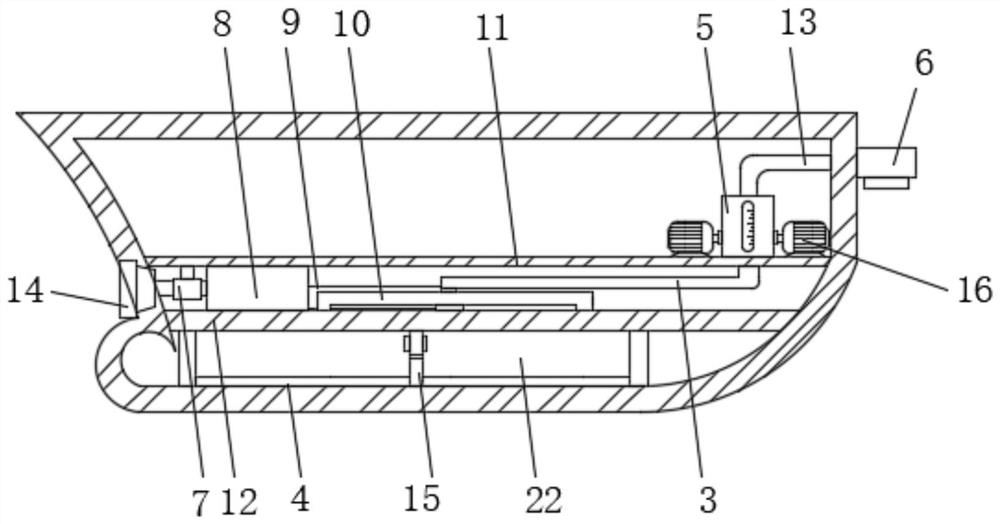

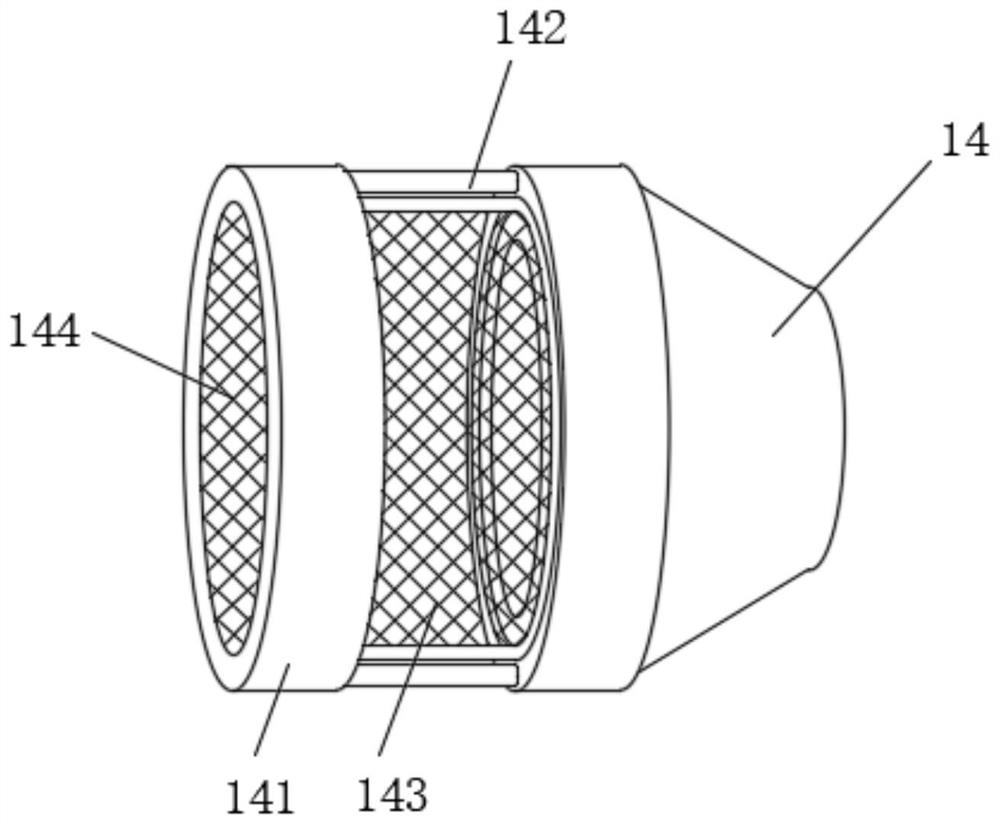

[0044] Embodiment 2: When adding ballast water to the ballast tank 22, adjust the valve 44 at the connection between the suction pipe 3 and the water inlet pipe, turn on the water pump 21 to carry out pumping work, so that the external seawater passes through the first screen 143 outside the filter device 14 Entering the interior of the linkage device 7, the flowing water drives the turbofan 71 to rotate at a high speed, the first gear 72 on the right side of the turbofan 71 drives the first bevel gear 73 to rotate, the first bevel gear 73 drives the driving gear 74, and the driving gear 74 drives the right The second bevel gear 75 on the side rotates, the second bevel gear 75 drives the second gear 76 at the bottom to rotate, and the second gear 76 drives the acid stirring rod 17 to rotate at a high speed to stir and neutralize the seawater inside the adsorption box 8, and then the seawater passes through The upper water pipe 9 enters the inside of the ballast tank 22 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com