Cable shelf type winding device based on automation technology

An automation technology and a technology of a winding device, which are applied in the directions of transportation and packaging, transportation of filamentous materials, and thin material processing, etc., can solve the problems of large limitations and the inability of moving wiring blocks to move in the opposite direction, so as to reduce the difficulty, The effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

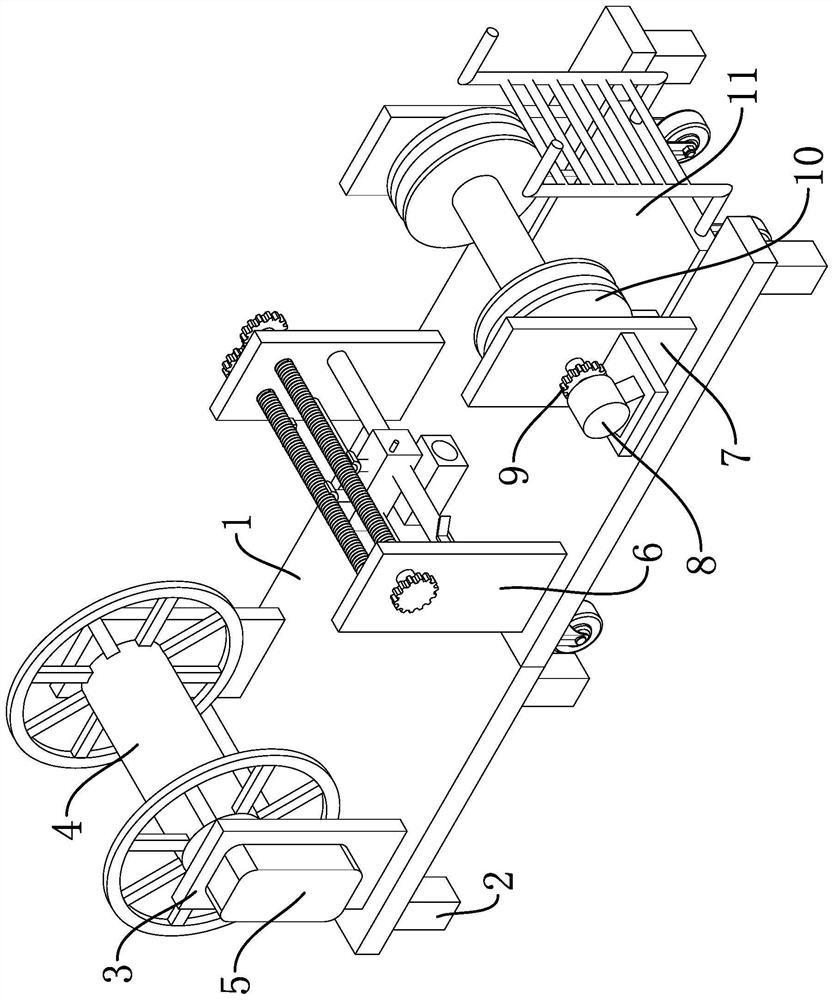

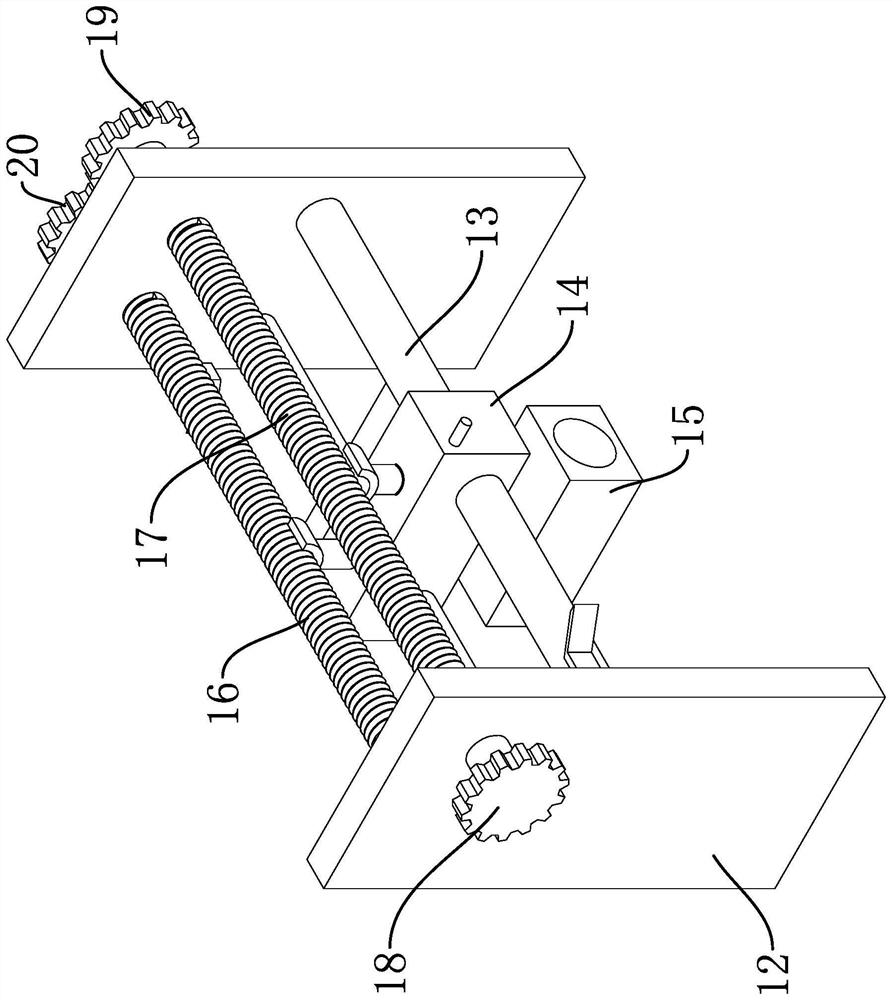

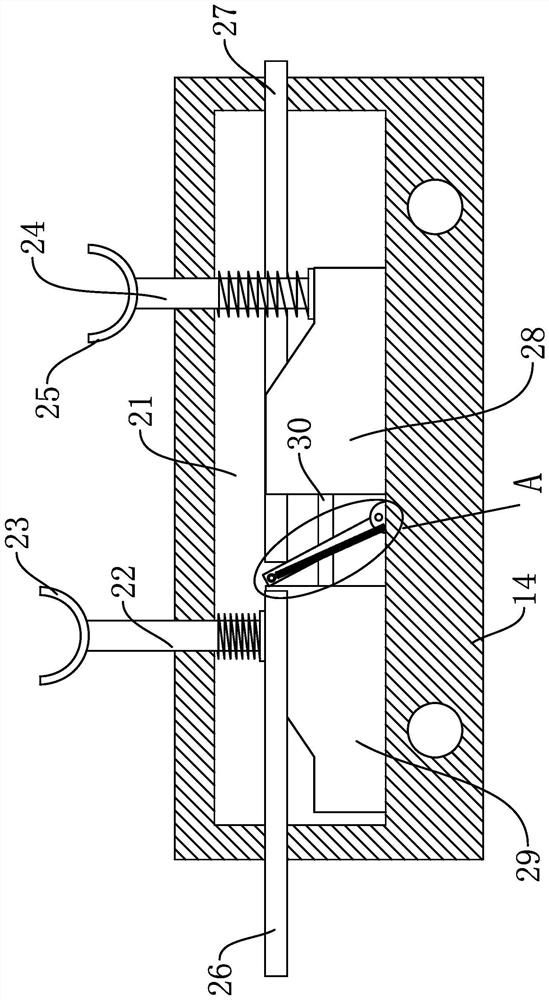

[0045] Such as Figure 1-Figure 10 As shown, the cable rack type winding device based on automation technology includes a base 1, a number of legs 2 are fixed on the lower side of the base 1, an unwinding mechanism is provided on the upper left end of the base 1, and an upper middle part of the base 1 is provided. There is a cable arrangement mechanism 6, a slot is provided on the right side of the base 1, and a winding mechanism 11 is arranged in the slot, and a winding driving mechanism is arranged on the upper right end of the base 1, and the winding driving mechanism includes two first vertical plates 7. A first motor 8 is fixed on the front side of the first vertical plate 7 on the front side. The output end of the fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com