Flexible electric heating demisting optical film and preparation method thereof

A flexible electrical and optical film technology, applied in the direction of transparent/reflective heating devices, conductive adhesives, film/sheet release coatings, etc., can solve the problems of poor electric heating stability, unoptimized structural design, structure and process flow Complicated problems, to achieve the effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In order to better illustrate the purpose, technical solutions and beneficial effects of the present invention, the present invention will be further described below in conjunction with specific examples. It should be noted that the following implementation methods are further explanations of the present invention, and should not be regarded as limitations of the present invention.

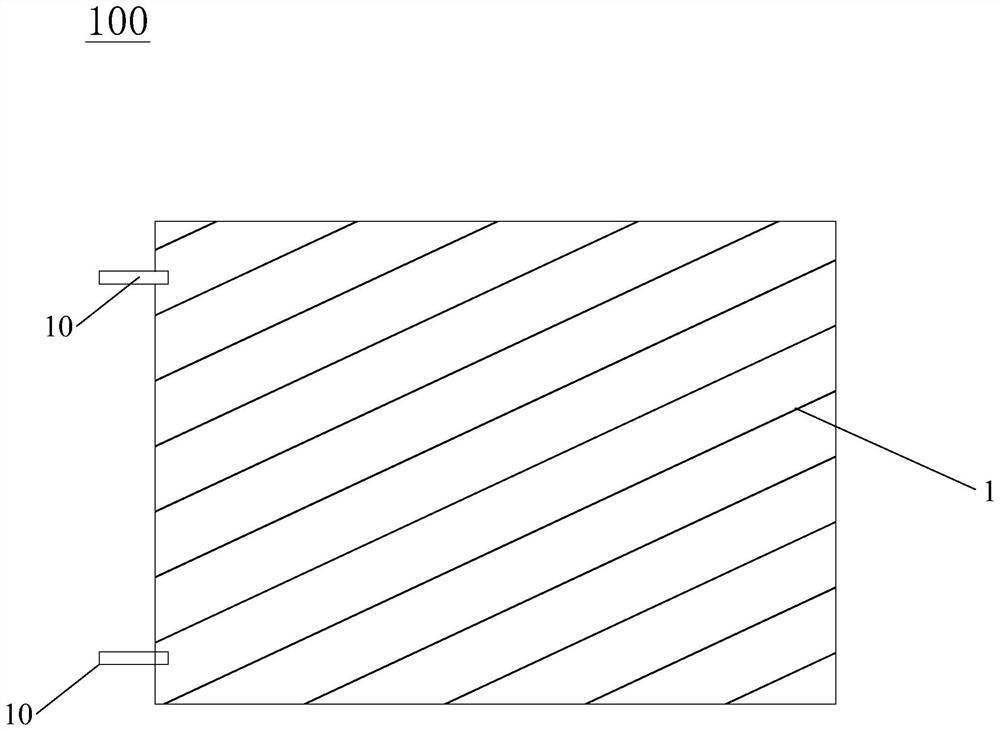

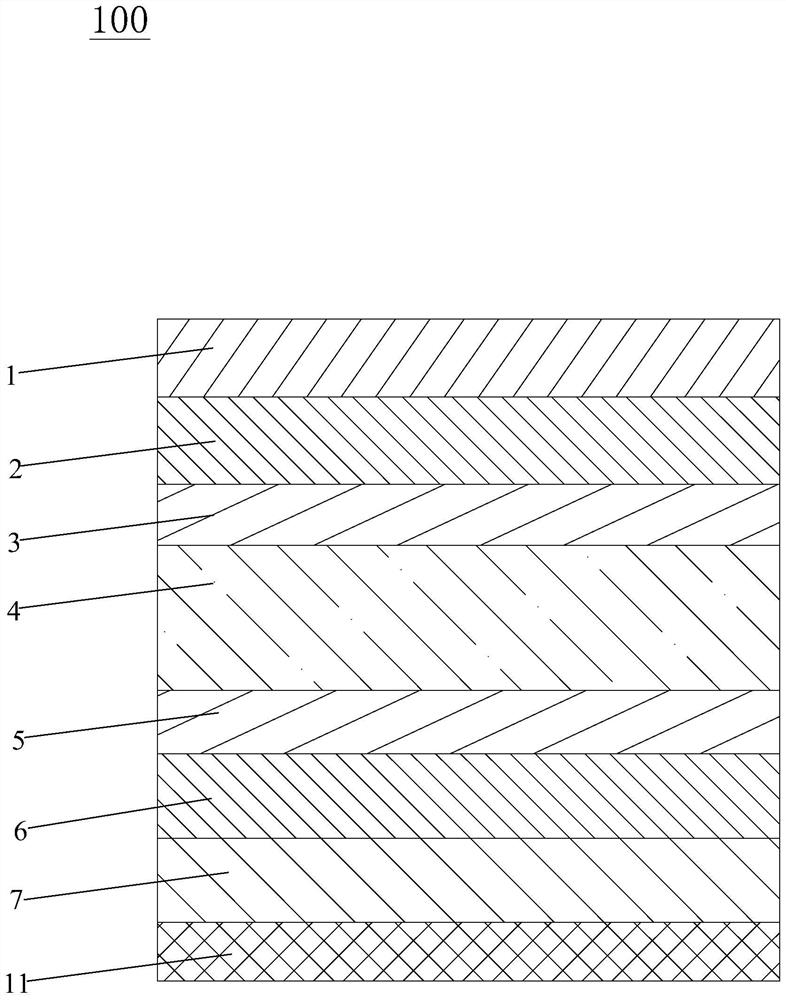

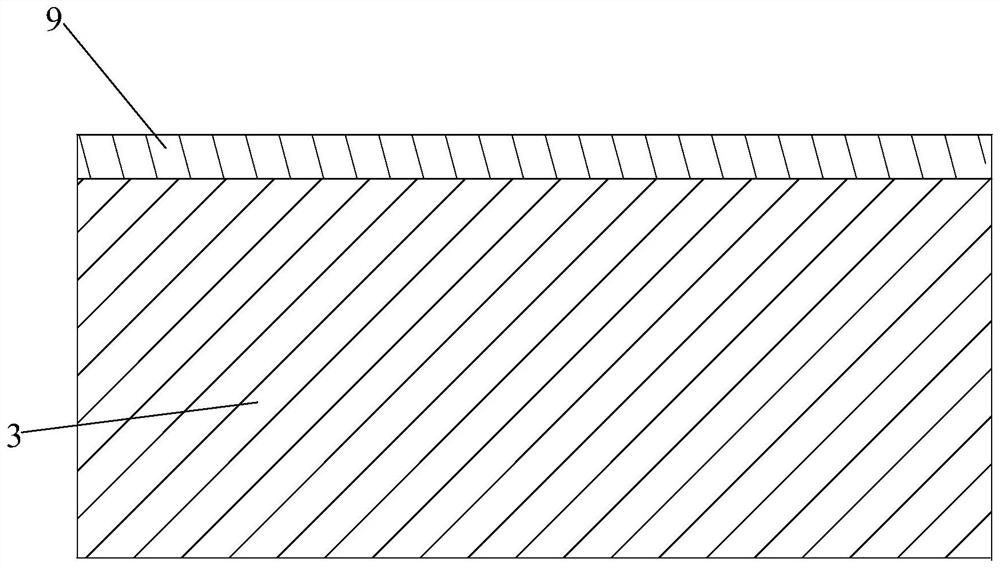

[0037] Such as Figure 1-2 , the flexible electrically heated defogging optical film 100 of the present invention comprises a laminated protective layer 1, a first transparent base film 2, a first transparent conductive primer layer 3, a transparent electric heating layer 4, and a second transparent conductive primer layer 5. The second transparent base film 6 , the pressure-sensitive adhesive layer 7 and the release film 11 . One side of the first transparent base film 2 forms a first transparent conductive base coat 3, and the other side of the first transparent base film 2 has a protect...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com