Adjustable constant-shooting-speed rock breaking sprayer

An adjustable rock-breaking nozzle technology, which is applied in the direction of drilling with liquid/gas jets, can solve the problems of increasing the resistance of the drilling process, shortening the life of the nozzle, and irregular holes of the jet, so as to improve the quality and rock-breaking efficiency. Avoid fluctuations in liquid displacement and reduce rock-breaking drilling resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

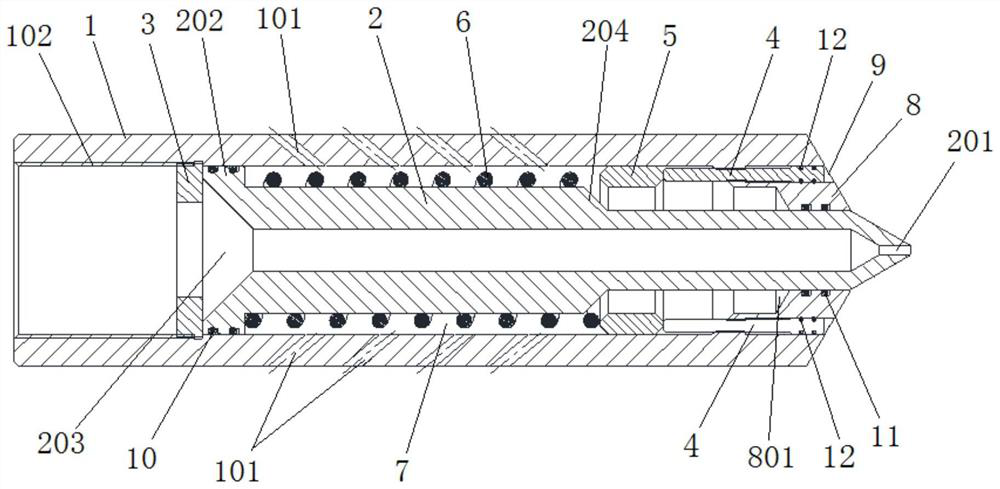

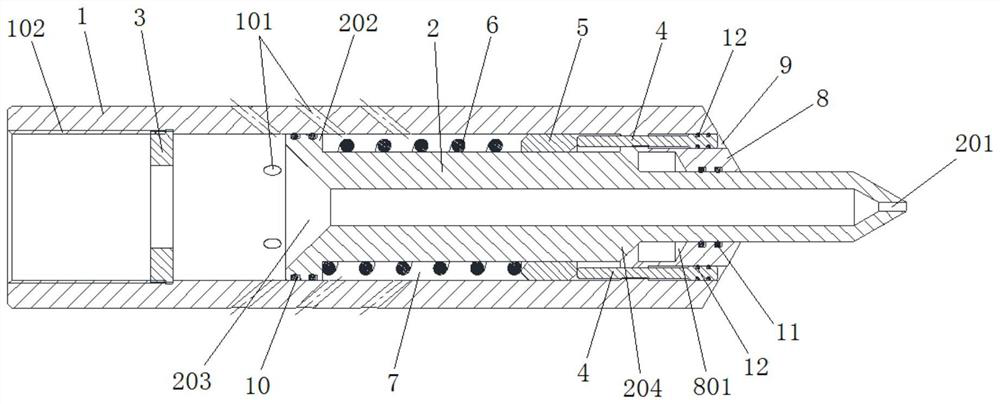

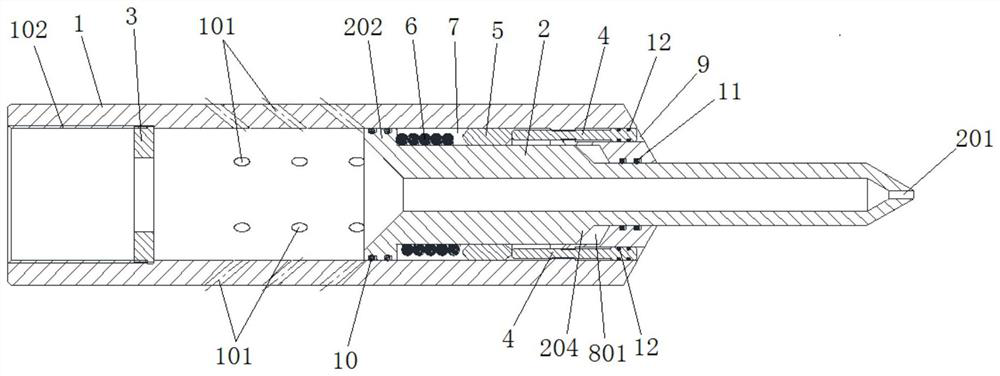

[0043] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described with reference to the accompanying drawings.

[0044] In this application, words indicating direction, such as left and right, are attached figure 1 The left and right directions in the guideline shall prevail, which shall be explained together here.

[0045] Such as Figure 1 to Figure 5 As shown, the present invention provides an adjustable constant rate of fire rock-breaking nozzle. The adjustable constant rate of fire rock-breaking nozzle includes a casing 1 and a nozzle 2. The casing 1 is a cylindrical structure with openings at both ends. The nozzle 2 One end of the nozzle is formed with a pressure-receiving part, and the other end of the nozzle 2 is provided with an injection port 201 axially penetrating inside the nozzle 2. The first open end is connected with the ext...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com