System, method and device for detecting and removing foreign matters on surface of fine blanking die on line

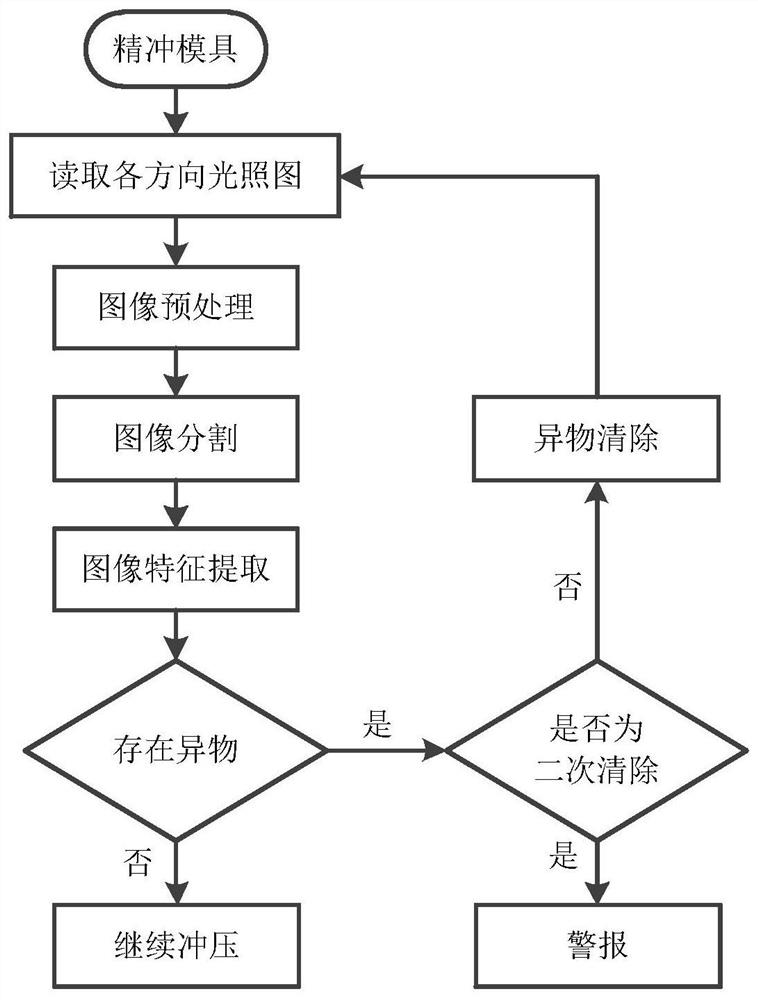

A cleaning system and foreign matter removal technology, which is applied to the cleaning method using tools, measuring devices, cleaning methods and utensils, can solve problems such as product failure, mold damage, and foreign matter residue in the mold, so as to avoid mold damage and ensure safety. , the effect of rapid detection and removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

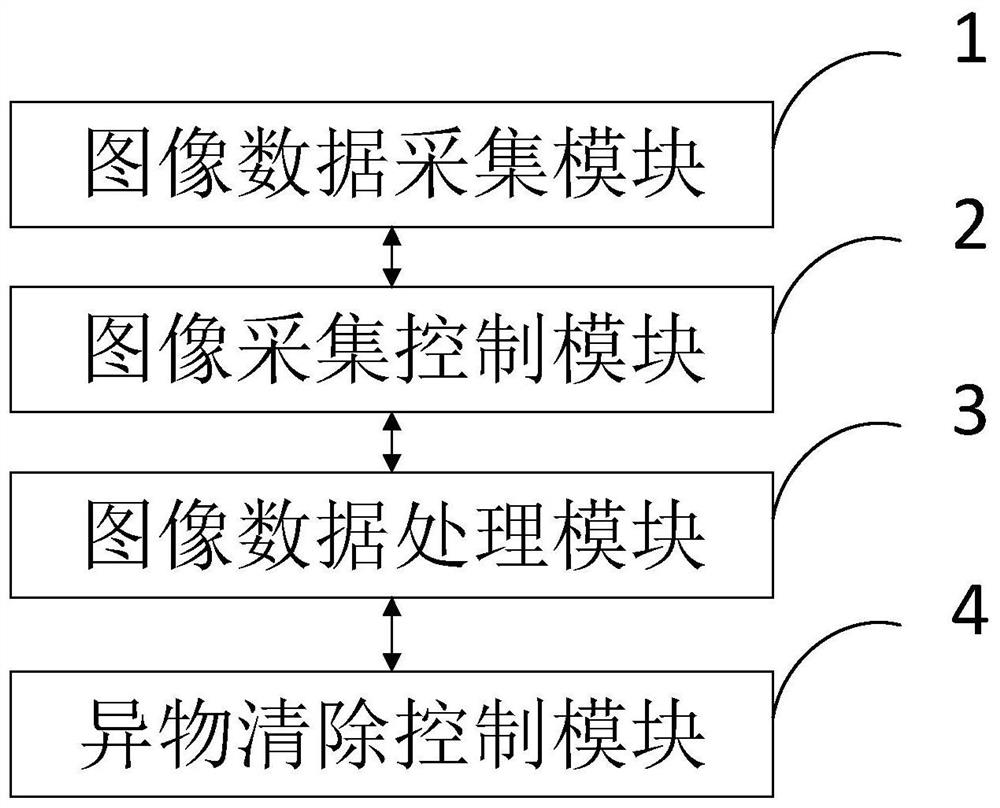

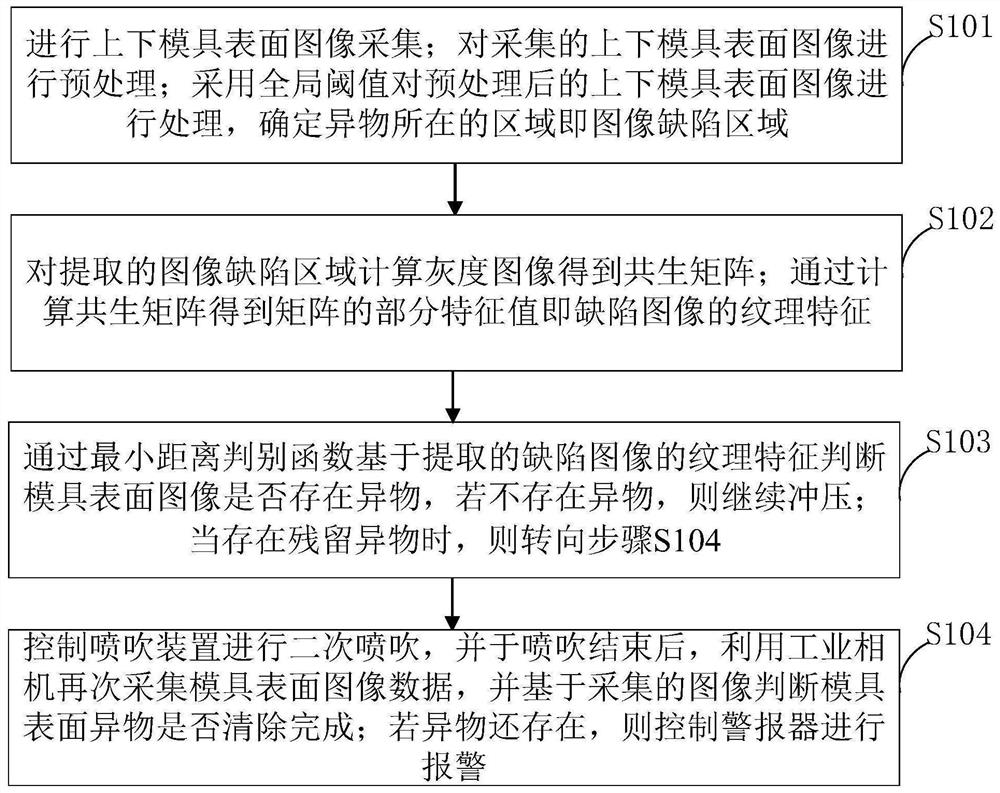

[0118]A device and method for online detection and removal of foreign matter on the surface of a fine blanking die include an image data acquisition system, an image acquisition control system, an image data processing system, and a foreign matter removal control system.

[0119] The image data acquisition system includes: industrial camera, combined light source, displacement sensor, slide table, telescopic bracket, guide rail. The industrial cameras are respectively fixed on telescopic brackets, and the telescopic brackets are installed on the rotary joint of the sliding table, and the position and angle are regulated by the sliding table. The sliding table and the guide rails are connected by sliding, and the guide rails are fixed on the inner walls on both sides of the fine blanking machine. superior. The combined light sources are fixed in front of the camera at the same angle. The displacement sensor is installed outside the lower mold table. According to the electrica...

Embodiment 2

[0153] The overall schematic diagram of the online detection and removal device for foreign matter on the fine blanking die surface of the present invention is as attached Figure 4 shown. It includes image data acquisition system, image acquisition control system, image data processing system and foreign matter removal control system.

[0154] The image data acquisition device is composed of an industrial camera 3-1, a combined light source 3-2, a slide table 3-3, a telescopic support 3-4, and a guide rail 3-5.

[0155] The industrial camera is a WP-UT miniature high-speed camera, and the combined light source is an LED combined light source.

[0156] Figure 4 to Figure 9 It is a schematic diagram of the image data acquisition device. The industrial camera 3-1 is fixed on the telescopic bracket 3-4, and the telescopic bracket 3-4 is installed on the rotary joint of the sliding table 3-3, and the position and angle are regulated by the sliding table 3-3. A sliding connecti...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap