Industrial process state monitoring method based on spectral radius-interval principal component analysis

A principal component analysis and industrial process technology, applied in the field of complex industrial process status monitoring, can solve the problems of not being able to distinguish between normal working conditions and abnormal working conditions, a large amount of calculation, and an increase in missed reports, so as to reduce the complexity and calculation amount , solve the feature decomposition problem, and improve the effect of robustness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

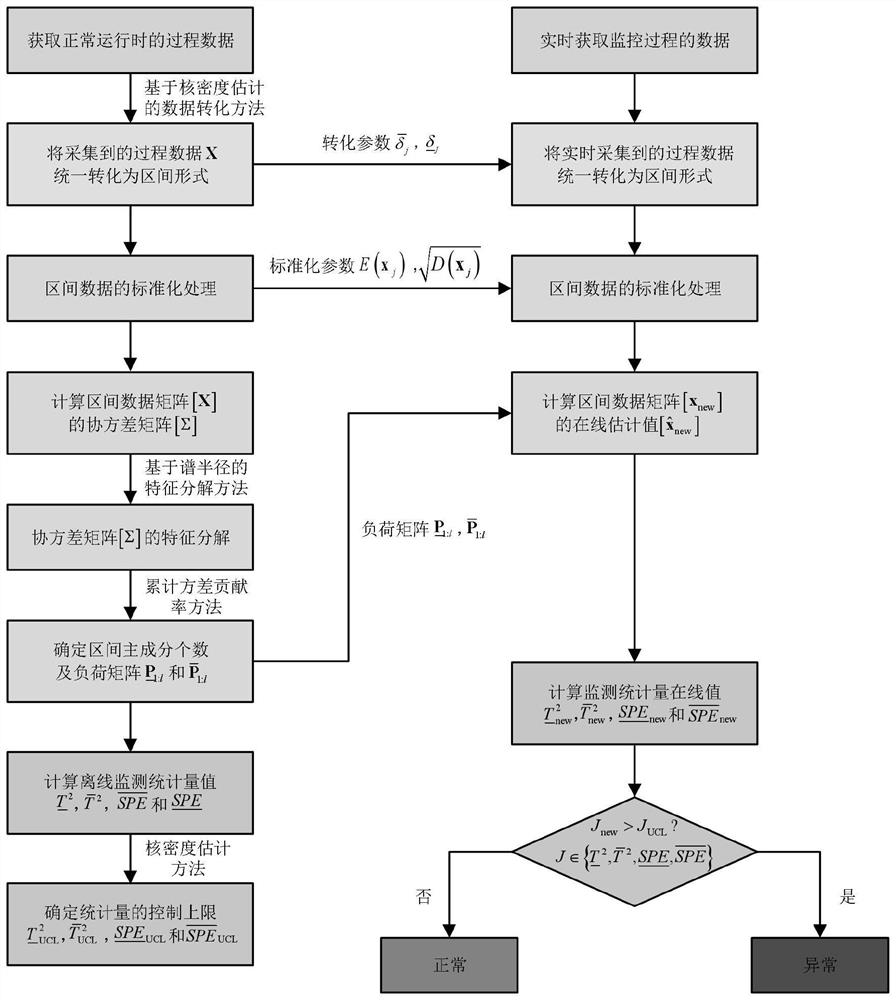

[0079] The invention relates to a condition monitoring technology for complex industrial processes containing inaccurate process data. Specifically, a data conversion method based on kernel density estimation is first proposed, which converts the data collected in the industrial process into an interval form; secondly, a process state monitoring method based on the spectral radius-interval principal component analysis algorithm is proposed, which realizes Feature extraction is performed on interval process data, and a process status monitoring model is established based on the extracted features to realize real-time online monitoring of industrial processes. The overall flow chart of the proposed state monitoring method for complex industrial processes based on spectral radius-interval principal component analysis algorithm is as follows: figure 1 As shown, the entire monitoring system mainly includes the following three parts: establishing a data conversion model based on ke...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com