Material taking manipulator for forging

A technology of retrieving manipulators and manipulators, which is applied in the field of forging processing to achieve high reliability, improve applicability, and prevent damage to manipulators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

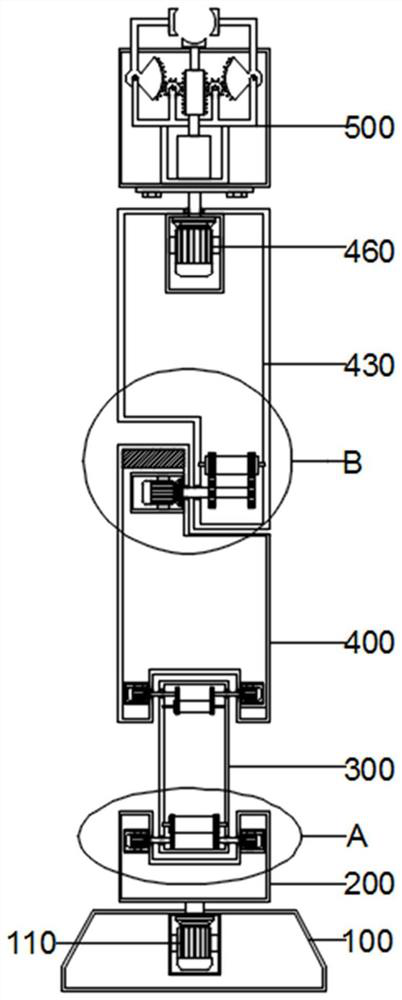

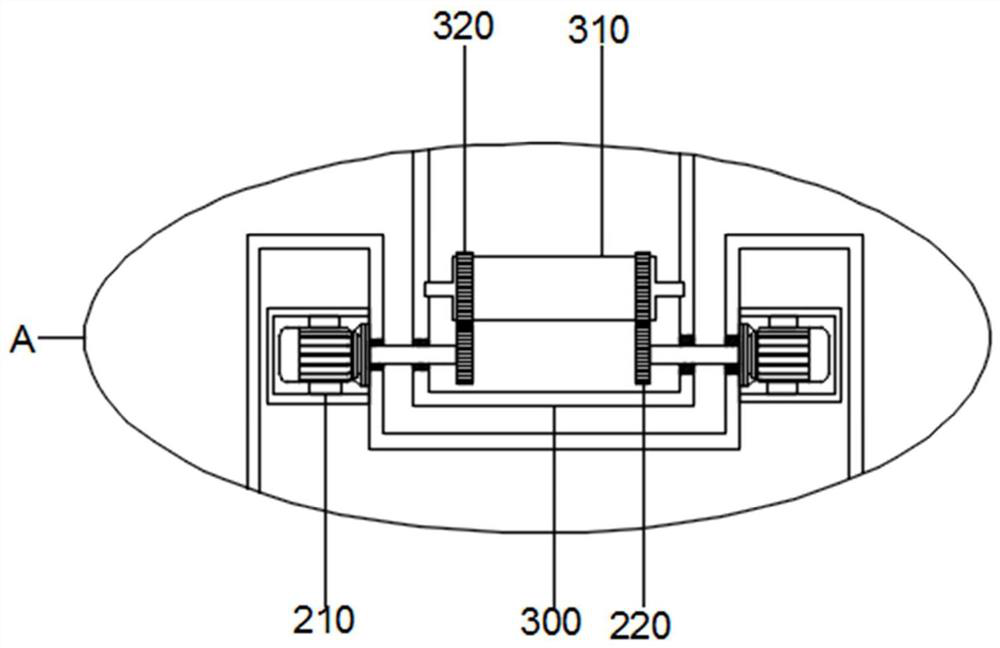

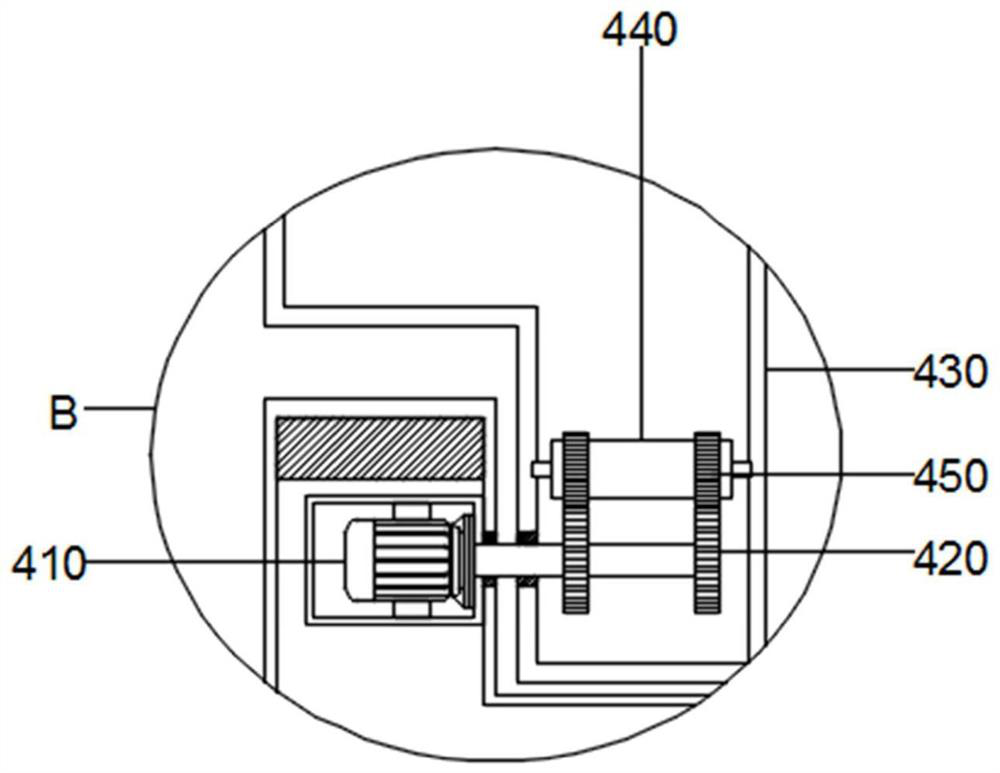

[0025] Refer to attached Figure 1-4 , a reclaiming manipulator for forging processing provided by the present invention, comprising a base 100, a movable joint 200, a connecting column 300, a movable joint 2 400 and a manipulator 500, the top of the base 100 is fixedly installed with a movable joint 200, and the top of the movable joint 200 Activity installation activity section two 400, activity section two 400 top activity installation activity section three 430, activity section three 430 top activity installation manipulator 500, manipulator 500 includes a protective shell 510, the inner wall of the protective shell 510 is fixedly connected to the installation frame 520, and the installation frame 520 includes Inner bracket 521 and outer bracket 522, inner bracket 521 and outer bracket 522 are all symmetrically provided with two groups, inner bracket 521 end movable installation gear 5 530, outer bracket 522 end movable installation splint frame 523, mounting frame 520 cen...

Embodiment 2

[0034] Refer to attached Figure 5, a reclaiming manipulator for forging provided by the present invention, comprising a base 100, a movable joint 1 200, a connecting column 300, a movable joint 2 400 and a manipulator 500;

[0035] Further, the manipulator 500 also includes a second outer guard plate 560 , and the second outer guard plate 560 is fixedly installed at the end of the splint frame 523 .

[0036] The use process of the present invention is as follows: when using the present invention, the outer guard plate 1 550 in Embodiment 1 is replaced by the outer guard plate 2 560, the present invention is installed in a suitable position outside the casting machine equipment, and then adjusted by controlling the motor 1 110 The direction of the movable section 1 200 makes the position of the manipulator 500 close to the side of the casting machine, and then adjusts the positions of the connecting column 300, the movable section 2 400 and the movable section 3 430 by driving...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com