Intelligent cutter machining equipment

A processing equipment and tool technology, applied in the field of intelligent tool processing equipment, can solve the problems of difficult to meet the requirements of material smoothness, irregular ripples, etc., and achieve the effect of improving the overall cleanliness, reducing irregular patterns, and improving grinding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

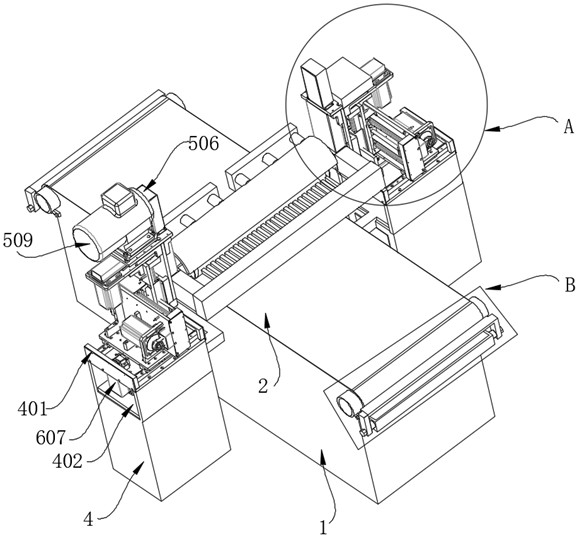

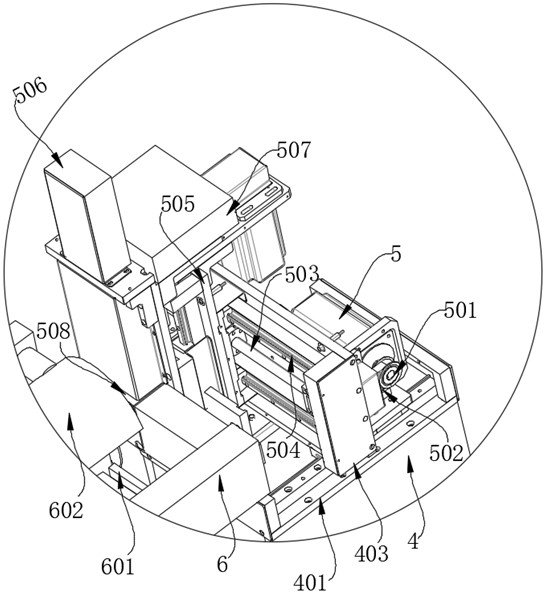

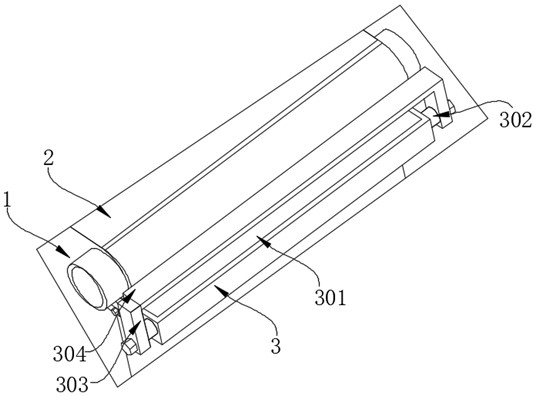

[0028] According to the manual attached Figures 1 to 9 , a kind of intelligent tool processing equipment, including a transmission support table 1 and a conveyor belt 2, a conveyor belt 2 is installed on the top of the transmission support table 1, and a transmission cleaning device 3 is provided on the front and rear sides of the conveyor belt 2, and the conveyor belt 2 There are grinding support frames 4 on the left and right sides;

[0029] The top of the grinding support frame 4 is provided with a mounting platform 401, the inside of the mounting platform 401 is equipped with a fixed plate 403, the outer surface of the fixed plate 403 is fixedly connected with a displacement drive device 5, and the inner surface of the fixed plate 403 The side is provided with a transmission mobile device 503, the inner side of the transmission mobile device 503 is movably connected with a moving plate 505, the inner side of the moving plate 505 is provided with a cleaning equipment rack ...

Embodiment 2

[0038] According to the manual attached Figures 1 to 5 , a kind of intelligent tool processing equipment, including a transmission support table 1 and a conveyor belt 2, a conveyor belt 2 is installed on the top of the transmission support table 1, and a transmission cleaning device 3 is provided on the front and rear sides of the conveyor belt 2, and the conveyor belt 2 There are grinding support frames 4 on the left and right sides;

[0039] The top of the grinding support frame 4 is provided with a mounting platform 401, the inside of the mounting platform 401 is equipped with a fixed plate 403, the outer surface of the fixed plate 403 is fixedly connected with a displacement drive device 5, and the inner surface of the fixed plate 403 The side is provided with a transmission mobile device 503, the inner side of the transmission mobile device 503 is movably connected with a moving plate 505, the inner side of the moving plate 505 is provided with a cleaning equipment rack ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com