Device and system for measuring a high of a surface of a rotating body

A technology of rotating body and raised part, which is applied in the direction of measuring device, rotary printing machine, rotary printing machine, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

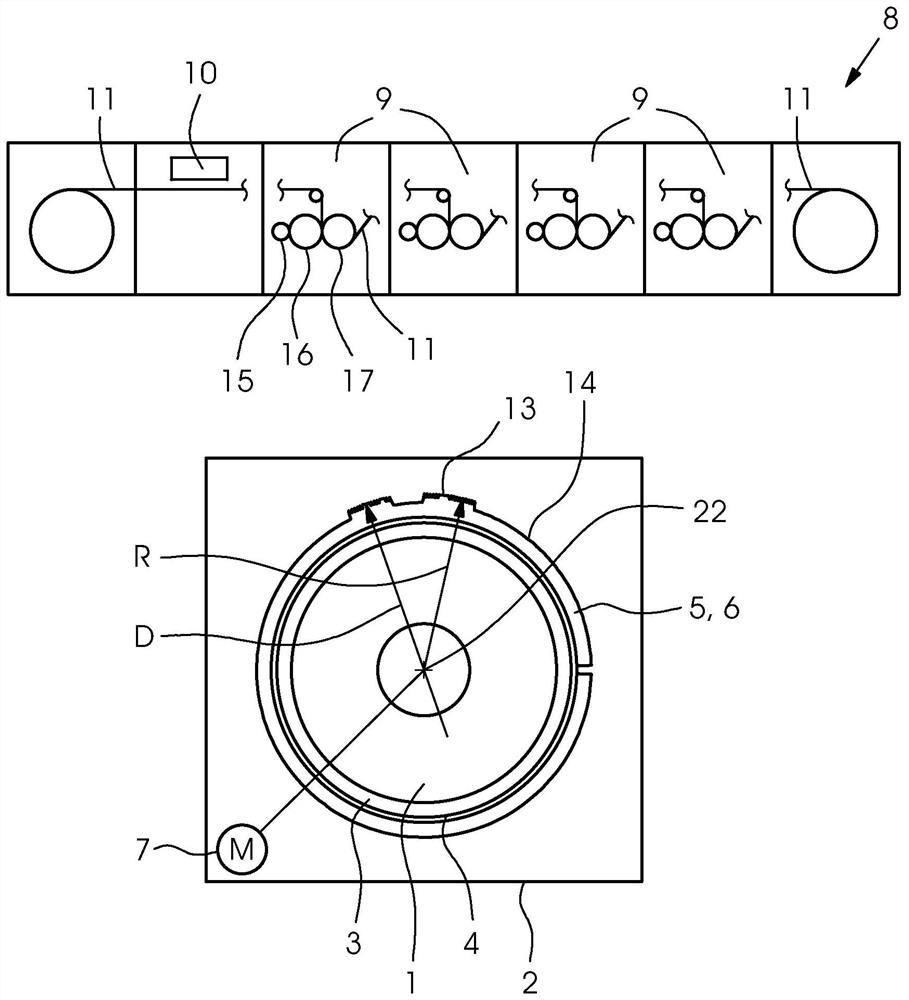

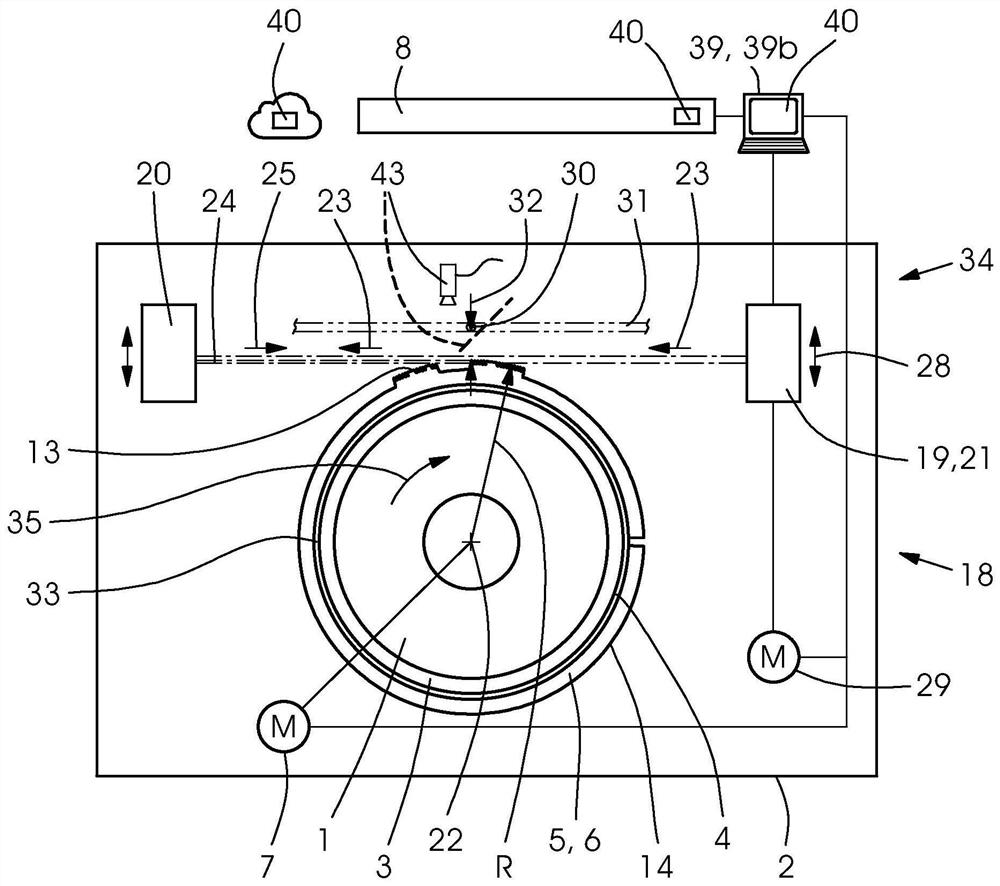

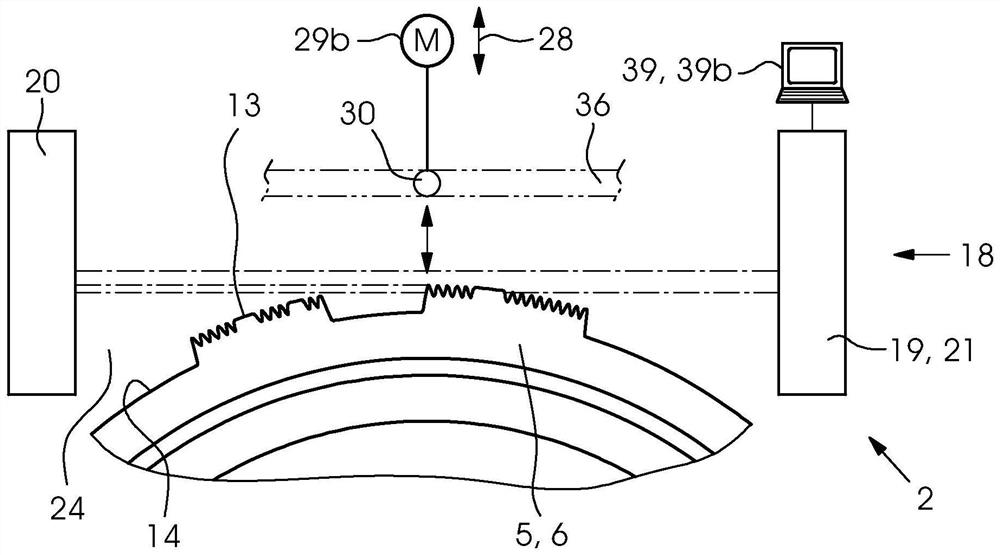

[0051] figure 1 Shown is a rotatable carrier roller 1 of a measuring station 2, a sleeve 3 accommodated on this carrier roller and a sleeve 3 accommodated thereon, preferably by means of an adhesive tape 4 (or alternatively by means of a glue coating of the sleeve). The (so-called) "setter", fastened on the sleeve 3 , the printing plate 5 to be measured at least with respect to its topography, acts as a cross-section of the rotating body 6 . Alternatively, preferably laser-etched printing sleeves can be measured on a carrier cylinder.

[0052] In order to rotate the carrier roller 1 during the measurement, a motor 7 may be present in the measurement station 2 . The measuring station 2 can be part of a so-called "mounter" in which the printing plate 5 is mounted on a carrier sleeve, or it can be arranged independently relative to the "mounter". The measuring station can be arranged independently of the printing press 8 , which is provided with at least one printing unit 9 fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com