800MPa-grade low-welding crack sensitivity steel plate and manufacturing method thereof

A technology with low welding cracks and a manufacturing method, applied in the field of iron and steel metallurgy, can solve the problem of high alloy cost, and achieve the effect of good toughness and plasticity and uniform structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

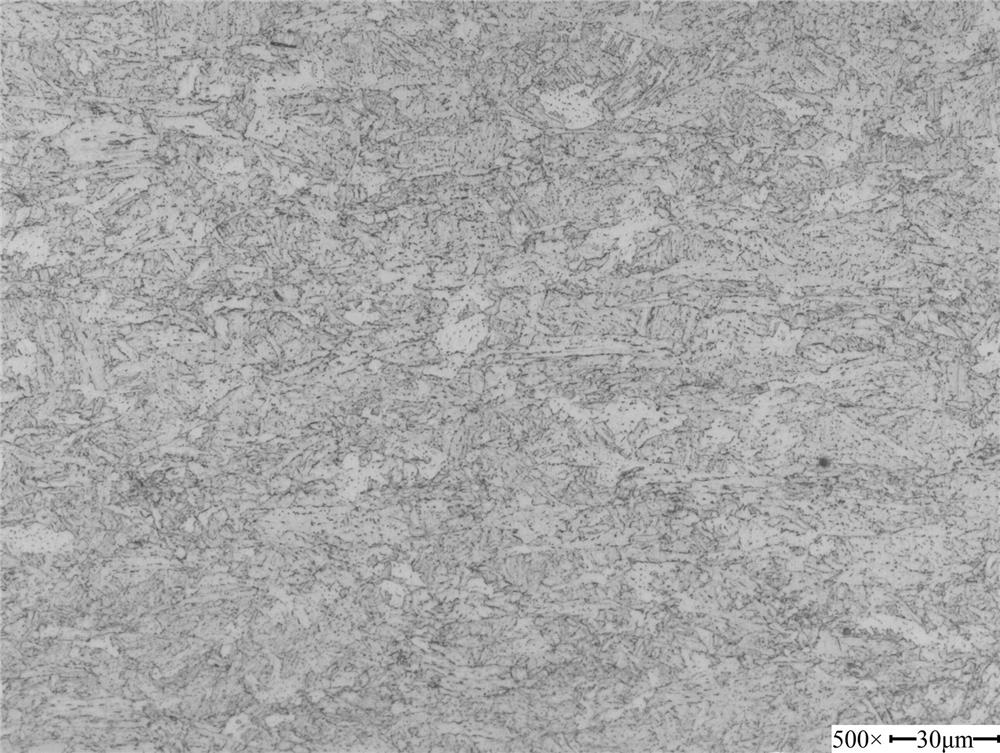

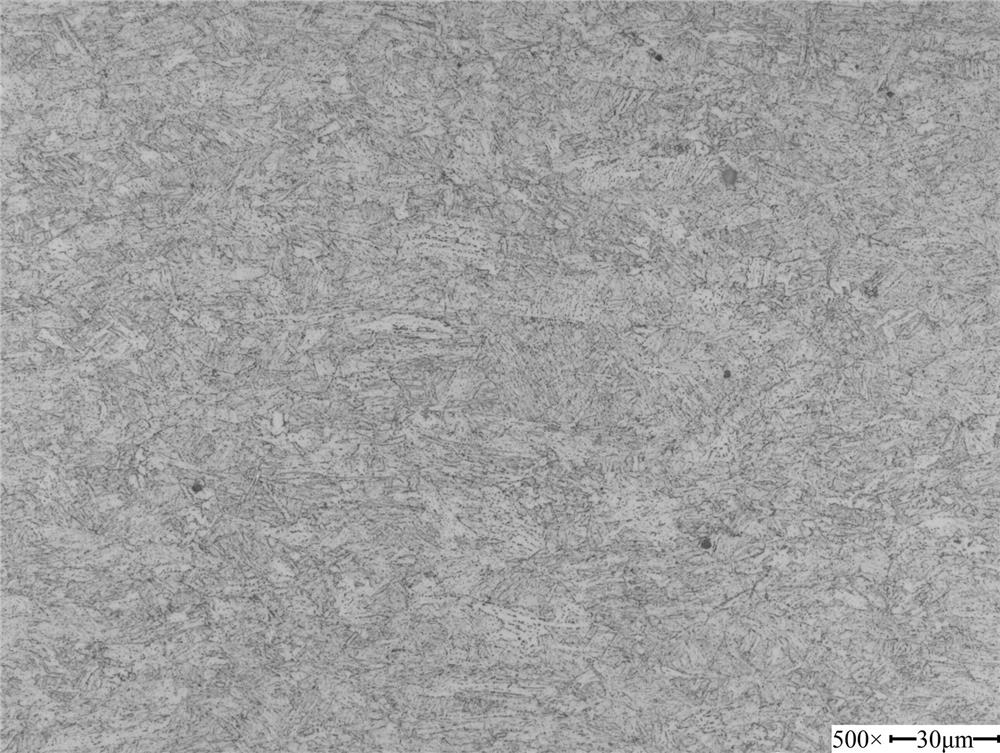

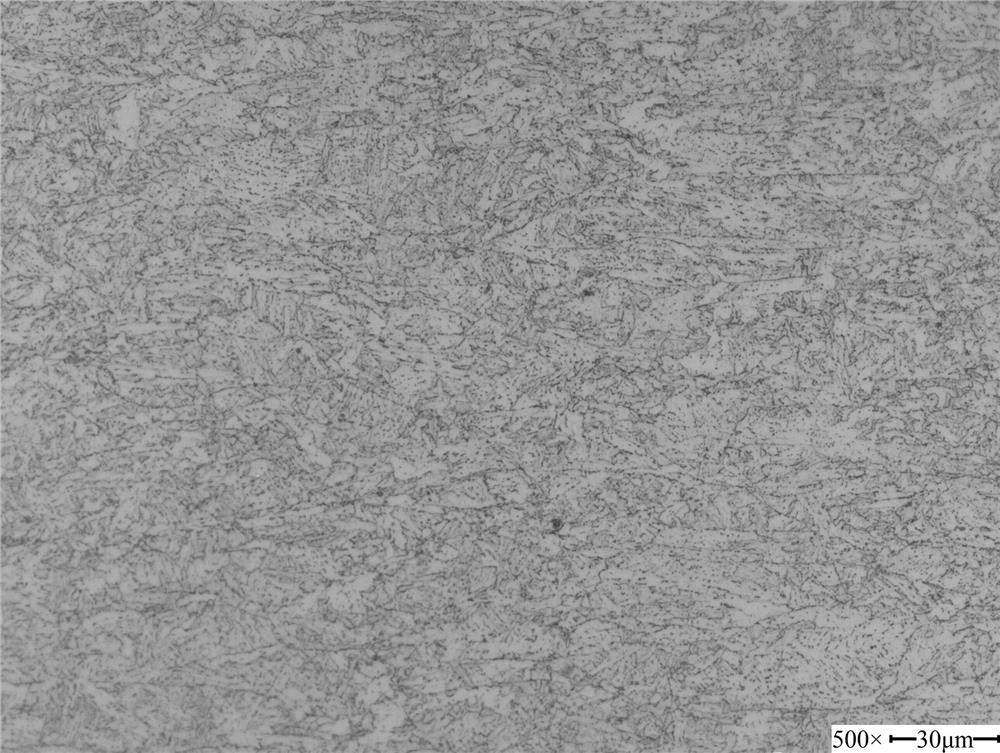

Image

Examples

Embodiment

[0026] An 800MPa grade low welding crack sensitivity steel plate, comprising the following chemical components in weight percentage: C: 0.06-0.08%, Si: 0.12-0.50%, Mn: 1.50-1.85%, P≤0.020%, S≤0.010%, Cr: 0.20~0.60%, Nb: 0.015%~0.060%, Alt: 0.010%~0.060%, Ti: 0.008%~0.035%, B≤0.005%, Mo≤0.08%, Ni:≤0.15%, Cu≤0.15 %, Pcm≤0.21, the balance is Fe and unavoidable impurities.

[0027] A method for manufacturing an 800MPa grade low welding crack sensitivity steel plate, comprising the following steps:

[0028] ① Slab reheating temperature: 1200-1250°C, and control the heating rate at 6-8°C / s, and keep the temperature at 1150-1250°C for not less than 30 minutes;

[0029] ②Rolling temperature range in recrystallization zone: 980~1150℃, total rolling reduction in recrystallization zone≥40%;

[0030] ③Rolling temperature range in the non-recrystallized area: the starting temperature of finish rolling is 870-930°C, the total rolling reduction in the non-recrystallized area is ≥60%, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com