Spinning sliver digital signal real-time monitoring device and system

A digital signal, real-time monitoring technology, applied in textiles and papermaking, etc., can solve the problems of high configuration cost, complicated processing conversion process and circuit, high system configuration cost, and achieve the effect of low information processing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

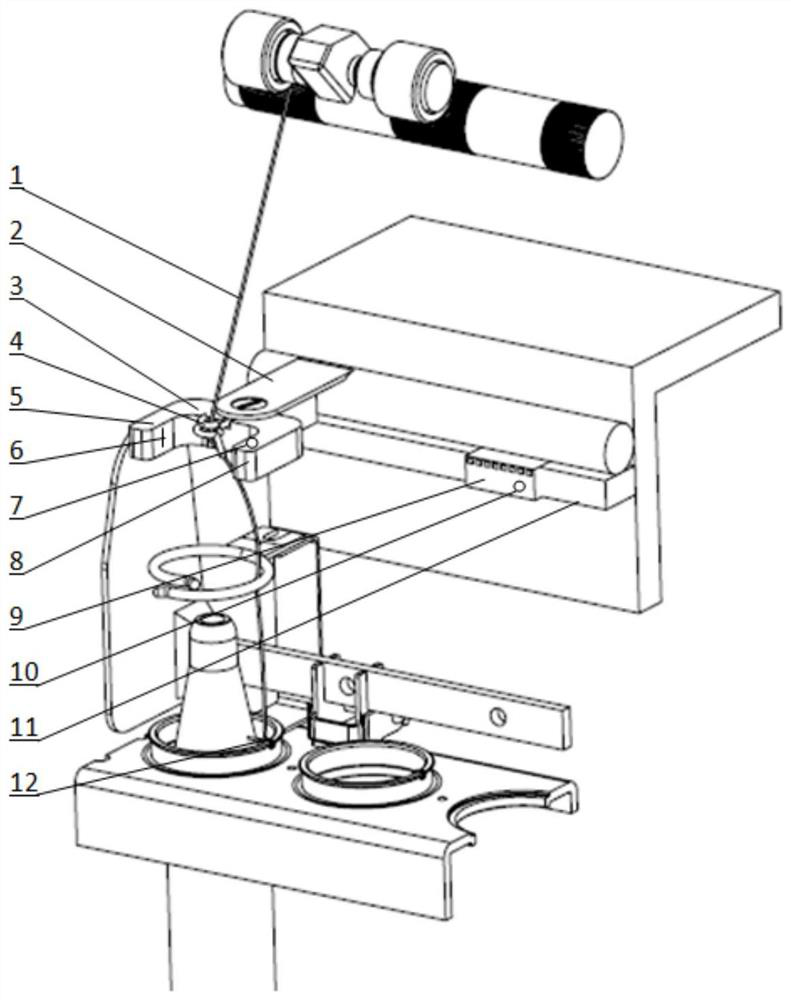

[0020] refer to figure 1 , real-time monitoring device for digital signal of spinning sliver, including sliver monitor and spindle position controller 3, section controller 9, sliver monitor 3 is composed of two arms of opposite beam photoelectric emission tube, photoelectric receiving tube and monitor frame 5 and 8, the emission and / or receiving window 6 of the photoelectric emission tube and the receiving tube inside the two arms of the monitor frame 5 and 8 are provided with a window structure that constrains or focuses the beam size, and the path through which the photoelectric emission tube transmits the light beam is called The optical path of the sliver monitor 3 is set at the yarn guide hole near the yarn guide 4, the sliver monitor 3 is combined with the spindle position controller 3, and the spindle position controller 3 is installed on the yarn guide plate 2.

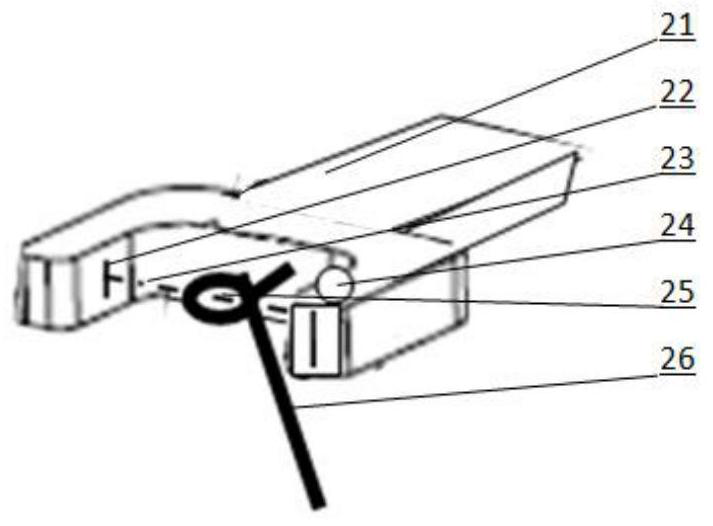

[0021] figure 2 It is a schematic diagram of the integrated combination of the sliver monitor 21 and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com