Washing machine

A technology of a washing machine and an electromagnetic heating device, which is applied in the field of washing machines, and can solve the problems of washing water containing debris such as lint, the heating failure of the electromagnetic heating device, and the burning of lint, so as to avoid the possibility of remaining on the electromagnetic heating device. Improve the washing effect of clothes and avoid the effect of dirt adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

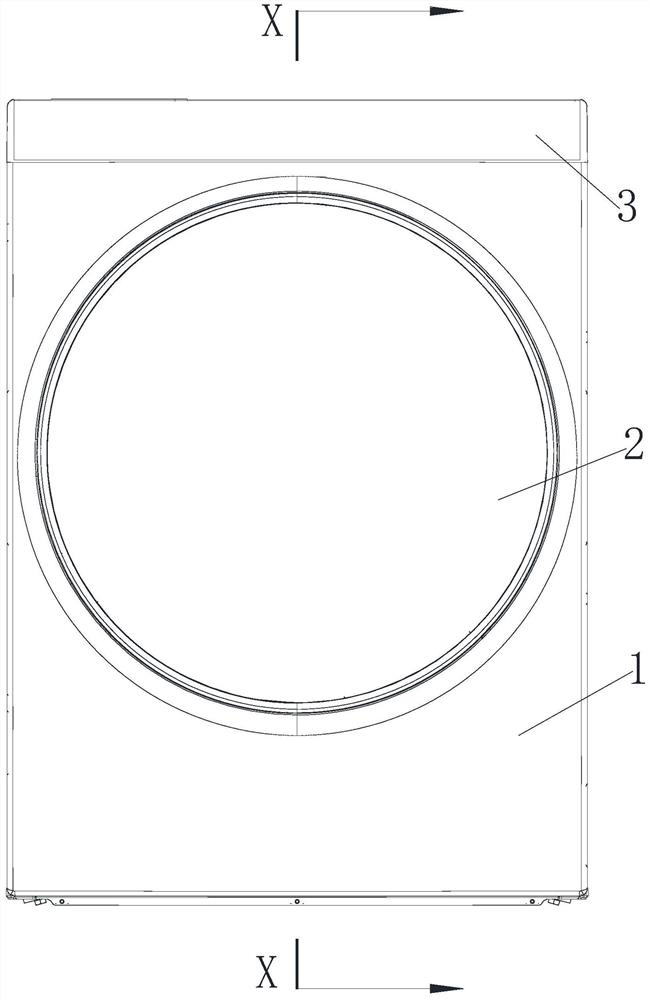

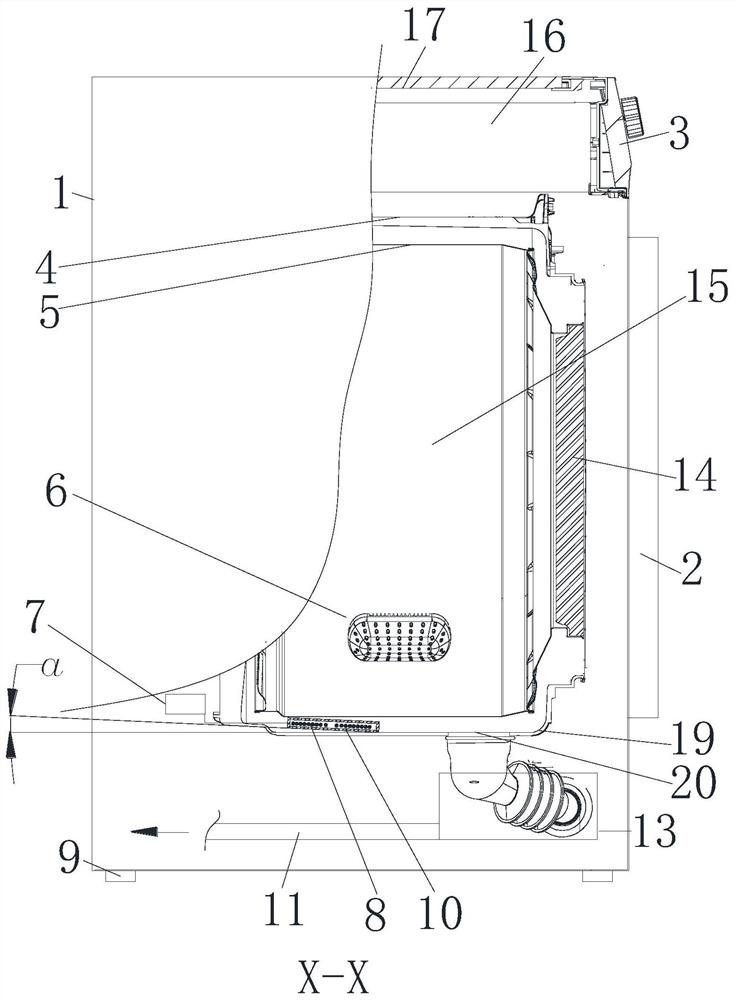

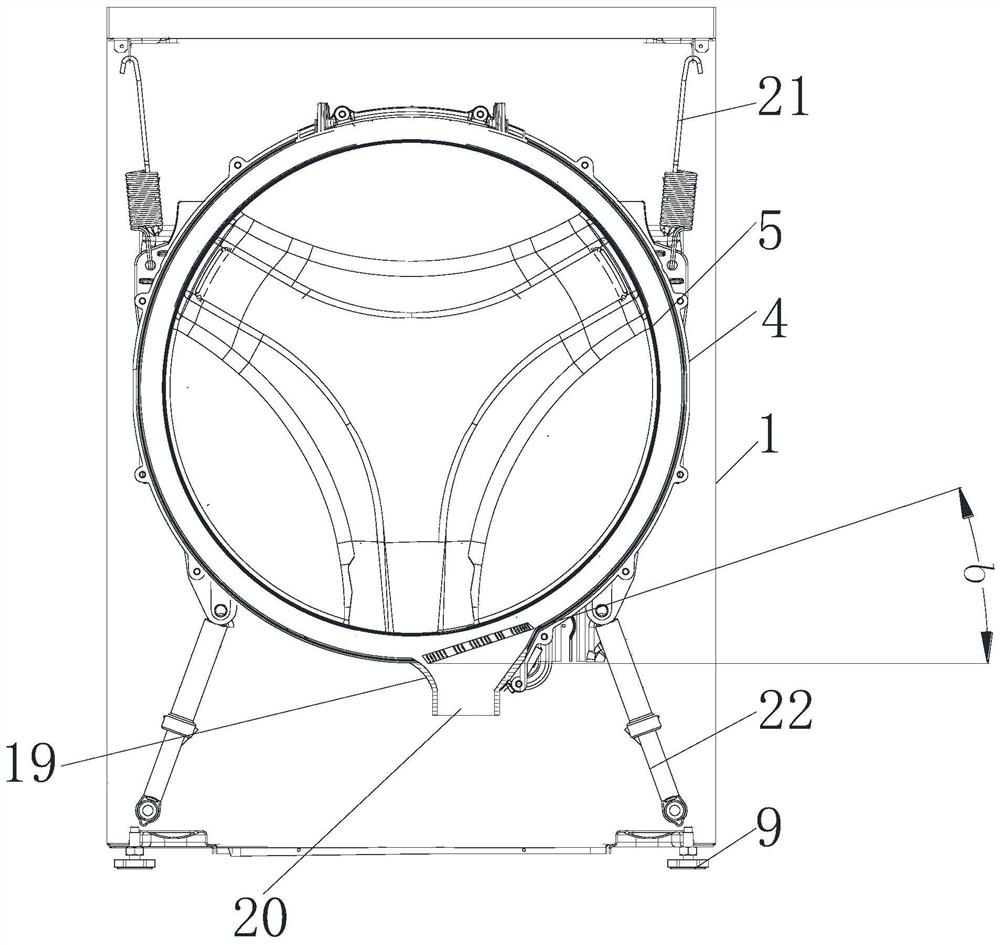

[0032] Such as Figure 1-Figure 3 Shown, a kind of washing machine of the present embodiment comprises:

[0033] An outer cylinder 4, the outer cylinder 4 is provided with a drain port 20;

[0034] The inner cylinder 5 is arranged in the outer cylinder 4 and has a washing chamber independently containing washing water;

[0035] And an electromagnetic heating device, which is arranged in the outer cylinder 4, and correspondingly heats the cylinder wall of the inner cylinder 5;

[0036] The electromagnetic heating device is arranged obliquely downward toward the water outlet 20, and / or the cylinder wall of the outer cylinder 5 is arranged obliquely downward from the location where the electromagnetic heating device is installed to the water outlet.

[0037] This embodiment adopts the wireless heating method of electromagnetic heating to realize the heating of the washing water of the washing machine without water between the inner cylinder and the outer cylinder during the was...

Embodiment 2

[0051] The control method of the washing machine in this embodiment includes: when the washing machine executes the last rinsing program and / or the dehydration program, the electromagnetic heating device is controlled to turn on the heating inner cylinder. This embodiment realizes the thermal dehydration of the clothes, the electromagnetic heating device heats the inner cylinder, and the clothes have a lower moisture content, which is convenient for quick drying / drying / drying, and improves the user experience.

[0052] Further, the dehydration program of the washing machine in this embodiment includes an accelerated dehydration stage in which the rotation speed of the inner tub gradually increases and a stable dehydration stage in which the rotation speed of the inner tub remains constant. The washing machine controls the electromagnetic heating device to turn on heating the inner tub at least in the accelerated dehydration stage.

[0053] When the washing machine in this embod...

Embodiment 3

[0068] Such as Figure 1-Figure 3 As shown, the present embodiment provides a washing machine, comprising:

[0069] Outer cylinder 4;

[0070] The inner cylinder 5 is arranged in the outer cylinder 4;

[0071] The electromagnetic heating coil 8 is arranged on the outer cylinder 4;

[0072] And the electromagnetic heating driver 7 is electrically connected with the electromagnetic heating coil 8, and the electromagnetic heating driver 7 rectifies the alternating current into direct current, and then converts the direct current into high-frequency alternating current;

[0073] The electromagnetic heating driver 7 outputs high-frequency alternating current to the electromagnetic heating coil 8, thereby generating a high-frequency alternating magnetic field, and the inner 5 generates heat due to electromagnetic induction in the high-frequency alternating magnetic field, thereby heating the inner The water in cylinder 5.

[0074] The heating / drying program of the washing machin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com