Artificial turf with hydrophilic surface and manufacturing process thereof

A technology of artificial turf and manufacturing process, which is applied in the direction of pavement, road, road, etc., can solve the problems of lawn fracture and bending, and achieve the effect of increasing resistance to pulling and deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

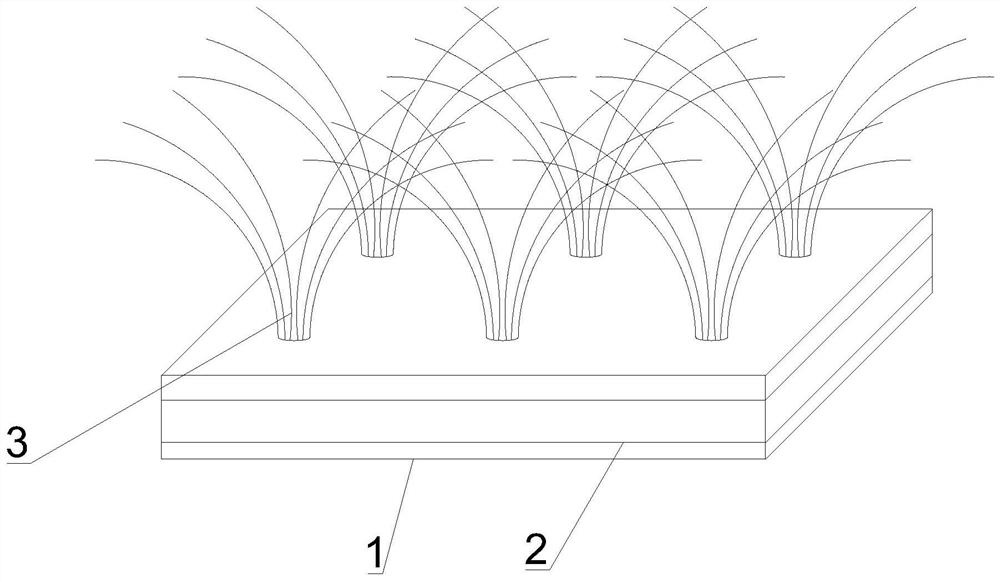

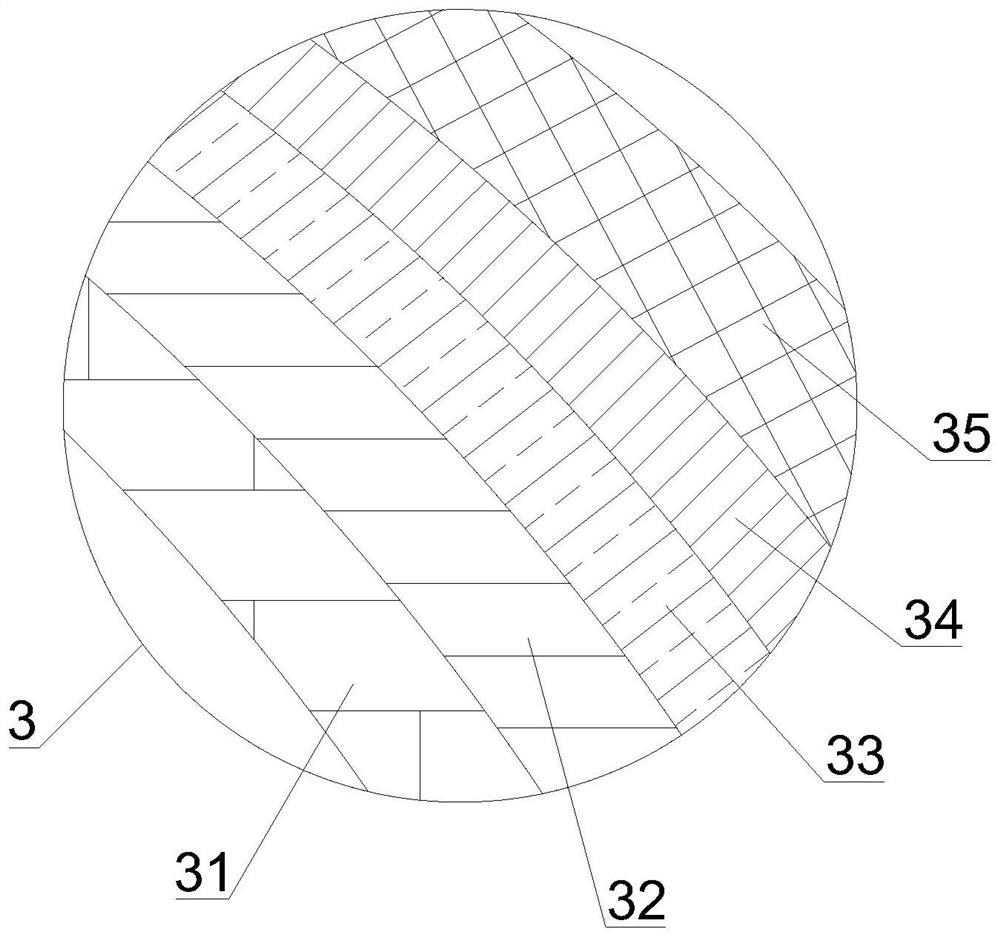

[0052] First aspect, such as Figure 1-9As shown, the present invention provides a kind of surface hydrophilic artificial turf, comprising artificial hydrophilic turf 1, artificial hydrophilic turf 1 comprising artificial turf 2, the top of artificial turf 2 is provided with hydrophilic grass 3, hydrophilic grass 3 includes Compression-resistant layer 31, the top outer surface of the compression-resistant layer 31 is provided with an anti-tear layer 32, the top outer surface of the anti-tear layer 32 is provided with a high-temperature resistant layer 33, and the top outer surface of the high-temperature-resistant layer 33 is provided with an anti-deformation layer. Layer 34, the top outer surface of the anti-deformation layer 34 is provided with a hydrophilic layer 35.

[0053] In this embodiment, the forage itself is compressed through the anti-compression layer 31, and it can stand up all the time. Cooperating with the anti-tear layer 32 and the anti-deformation layer 34, t...

Embodiment 2

[0055] Such as Figure 1-9 As shown, on the basis of Embodiment 1, the present invention provides a technical solution: preferably, triangular snap-in blocks 21 are arranged on the edges of both sides of the bottom of the artificial turf 2, and the inner surface of the artificial turf 2 slides and overlaps There is a forage limit clamping shell 22, the top of the forage limit clamping shell 22 is provided with a feeding elastic port 23, the inner surface of the feeding elastic port 23 is provided with a curved soft block 231, and one end of the curved soft block 231 is provided with Elastic rope 232 is arranged, elastic ring 233 is arranged on the both sides outer surface of bending soft block 231, and elastic soft block 24 is arranged on the both sides inner surface of forage limit snap-in case 22, the two sides of forage limit snap-in case 22 The outer surface of the side bottom is provided with a triangular groove 25, and the outer surface of both sides of the artificial tu...

Embodiment 3

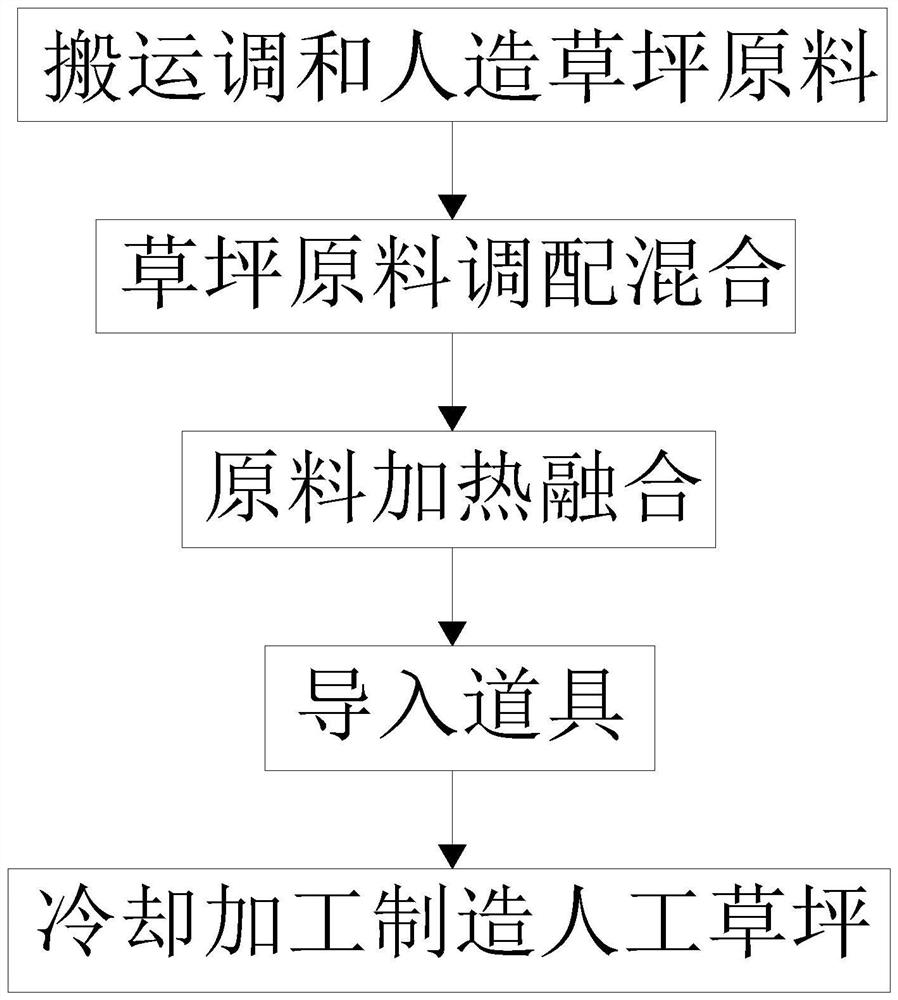

[0057] Second aspect, such as Figure 1-9 Shown, the present invention also provides a kind of surface hydrophilic artificial turf manufacturing process, the artificial turf manufacturing process of this surface hydrophilic, comprises the following steps:

[0058] Step 1. Handling and reconciling the artificial turf raw materials;

[0059] Step 2, lawn raw material deployment and mixing;

[0060] Step 3, raw materials are heated and fused;

[0061] Step 4. Import props;

[0062] Step five, cooling and processing to manufacture the artificial turf.

[0063] Wherein step two also includes the following steps:

[0064] Step A1, mixing 18-29% of the epoxy resin of the curing agent, 7-15% of the alcohol ether solvent and the rest of the water;

[0065] Step A2, then stir 7-13% of acrylic resin, 3.5-4.5% of alcohol ether solvent and the rest of the water;

[0066] Step A3, mixing step A1 and step A2 together, stirring for 20 minutes to 30 minutes for a long time, fully mixing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com