Geothermal circulation cooling method for high-temperature and high-humidity mine

A technology of circulating cooling, high temperature and high humidity, applied in the ventilation, heat pump, mining equipment of mines/tunnels, etc., can solve the problems of inability to fundamentally control the heat damage of mines, limited cooling effect, high investment cost, and improve heat source mining. Efficiency, power saving, safety enhancement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

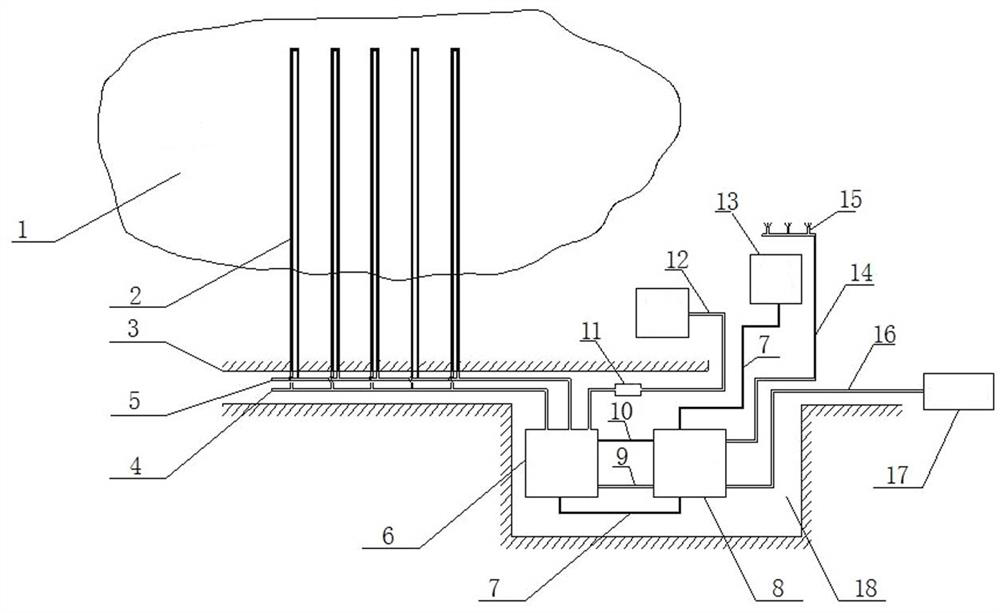

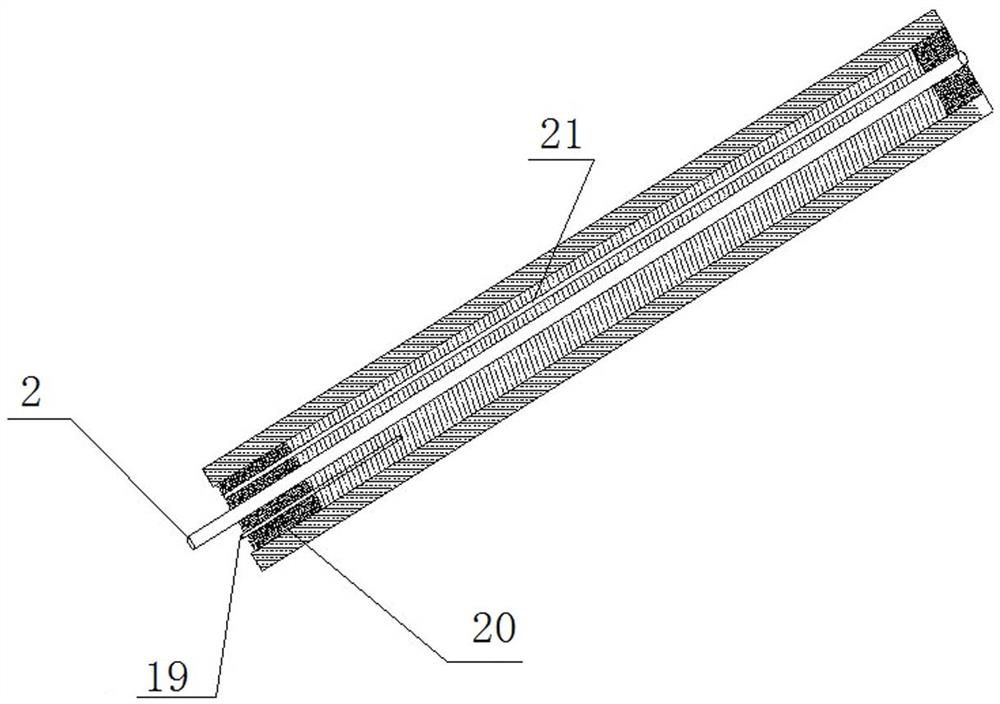

[0036] Example: such as Figure 1-2 As shown, a kind of high-temperature and high-humidity mine geothermal cycle cooling method of the present invention comprises the following steps:

[0037] S1. Determine the high-temperature heat source area 1 of mine mining through exploration, and preferentially select the area close to the mining face as the construction area of high-temperature heat source. According to the size and stored heat of the high-temperature heat source area, determine the water source heat pump 6, thermoelectric generator 8 and refrigeration system 13 scale and arrange equipment.

[0038] To ensure mine safety, the water source heat pump 6 and the thermoelectric generator 8 are required to meet coal mine safety standards and underground electrical safety standards, and are installed in the same dedicated underground chamber 18.

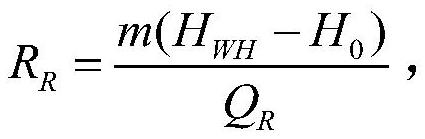

[0039] Among them, the heat storage in the high-temperature heat source area can be estimated by using the geothermal temperatur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com