Polar thermoelectric power generation system

A technology of thermoelectric power generation and box body, which is applied in the direction of generator/motor, electrical components, combustion product treatment, etc. It can solve the problem of non-removable and replaceable heat conduction parts, achieve effective fixed installation and disassembly, ensure use efficiency, and reduce replacement and the cost of maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

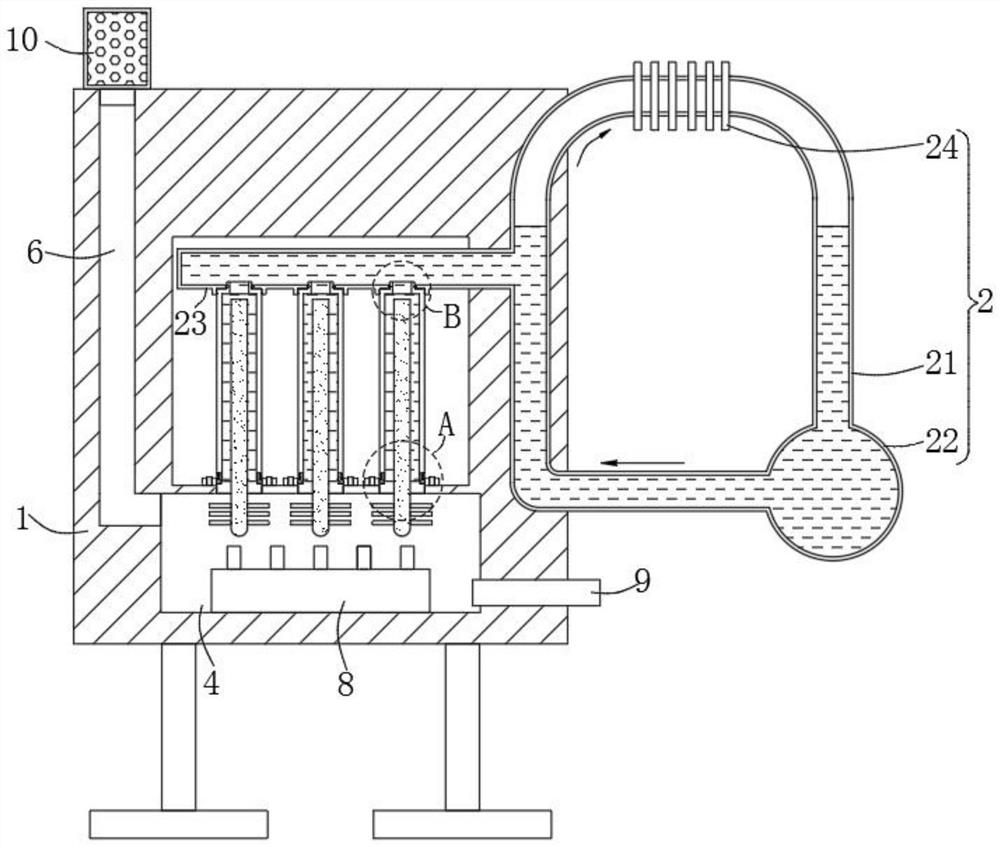

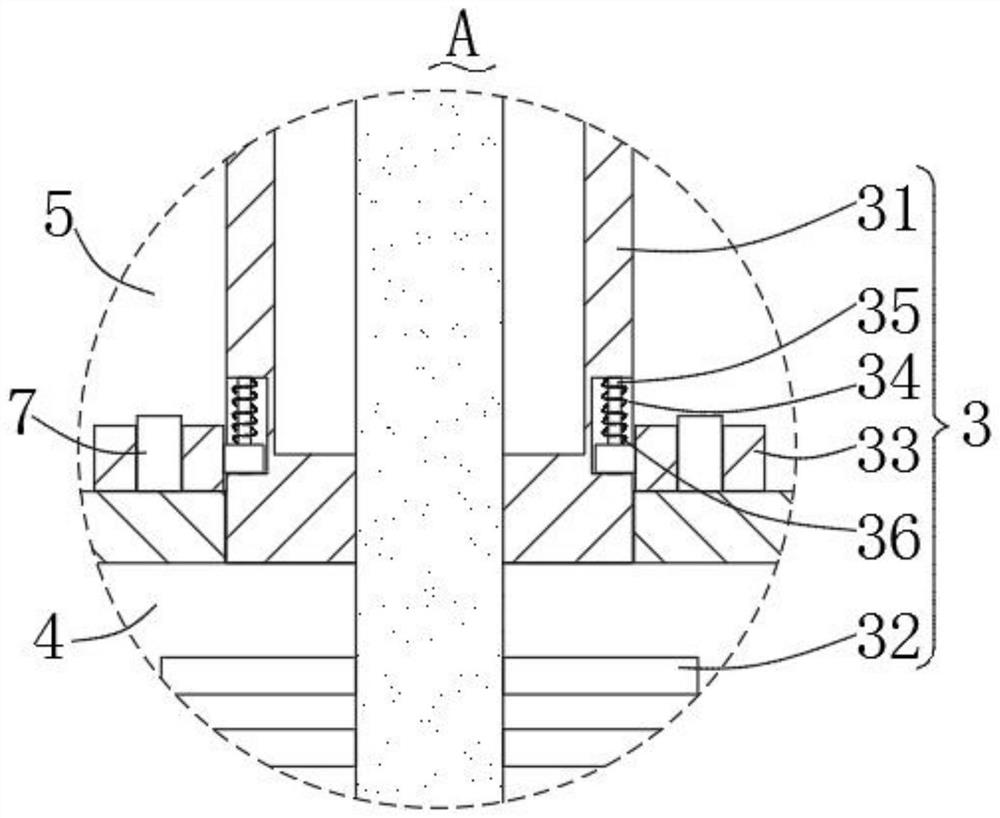

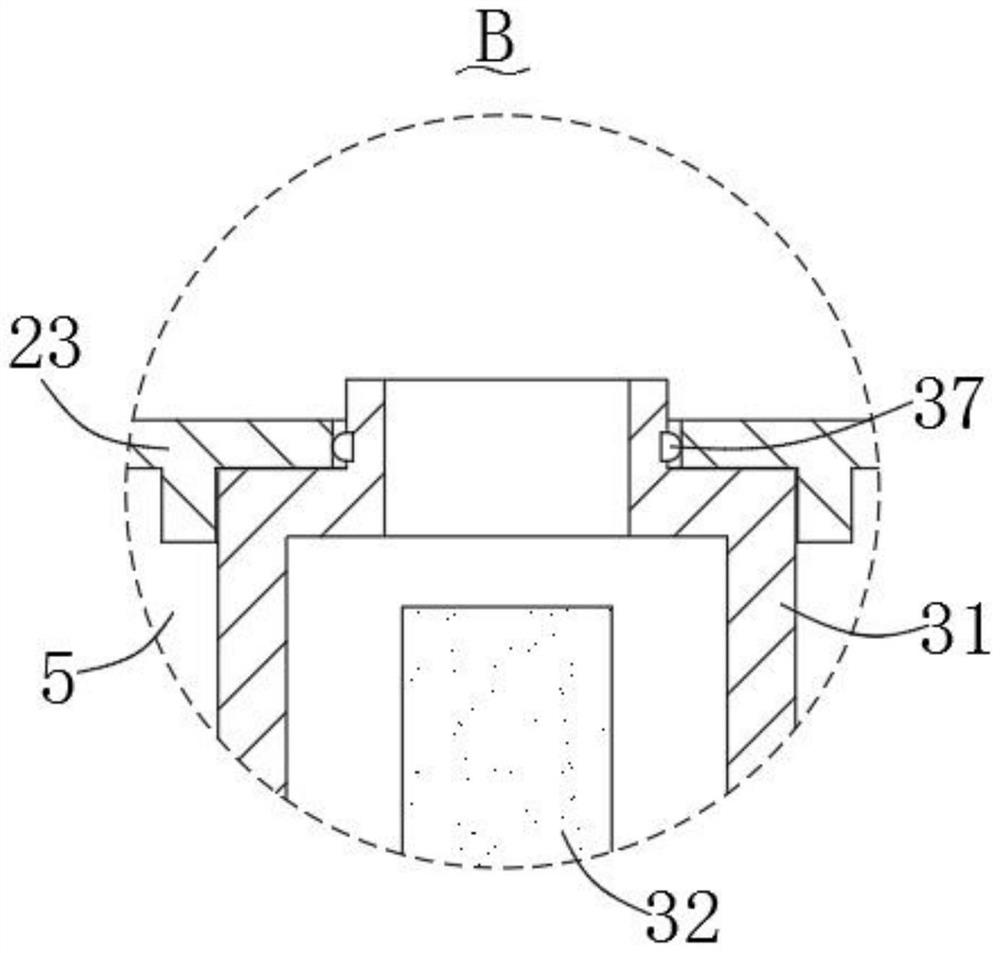

[0042] Please refer to figure 1 , figure 2 , image 3 , Figure 4 ,in, figure 1 A schematic structural diagram of the first embodiment of the polar thermoelectric power generation system provided by the present invention; figure 2 for figure 1 The enlarged schematic diagram of part A shown; image 3 for figure 1 The enlarged schematic diagram of part B shown; Figure 4 for figure 1 Schematic diagram of the exterior of the thermally conductive structure shown. Polar temperature difference power generation system, including:

[0043] A box body 1, a cooling structure 2, and a plurality of heat conduction structures 3 for heating the medium inside the cooling structure 2, wherein the cooling structure 2 is arranged on the box body 1, and the heat conduction structures 3 are installed on the One side of the cooling structure 2;

[0044] The heat conduction structure 3 includes a connecting pipe 31, on which a thermoelectric power generation assembly 32 is arranged, an...

no. 2 example

[0064] Please refer to Figure 5-6 , based on the polar thermoelectric power generation system in the first embodiment of the present invention, the second embodiment of the present invention provides another polar thermoelectric power generation system, wherein the second embodiment will not hinder the technical solution of the first embodiment Implemented independently.

[0065] Specifically, the present invention provides another polar thermoelectric power generation system with the following differences:

[0066] The box body 1 is provided with a cleaning structure 11 for cleaning the smoke and dust inside the flue exhaust duct 6, and the cleaning structure 11 includes a moving scraper 111 located below the flue exhaust duct 6 for driving the moving The scraper 111 moves the driving part 112 in the vertical direction and the magnetic block 113 for absorbing and fixing the bottom of the driving part 112. The outer side of the moving scraping part 111 is attached to the inn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com