One-way heat transfer heat pipe with Y-shaped flow guide table wick and machining method of one-way heat transfer heat pipe

A technology of deflectors and liquid-absorbing cores, which is applied to indirect heat exchangers, lighting and heating equipment, and modification using liquid cooling, etc. It can solve the problems of complex processing technology, damage to heating elements, and high cost, and achieve simple processing technology , low cost, universal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

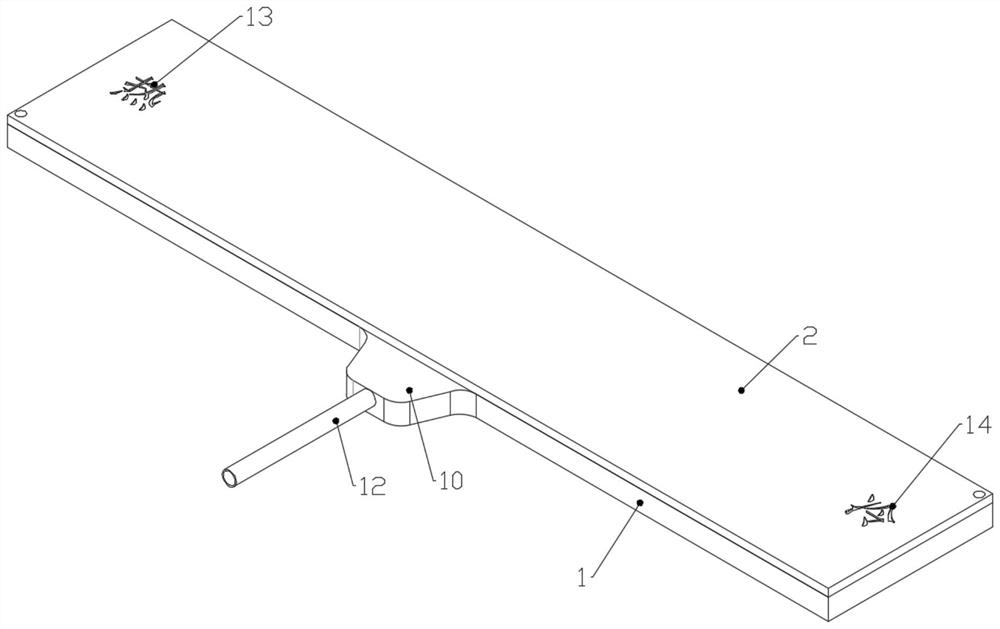

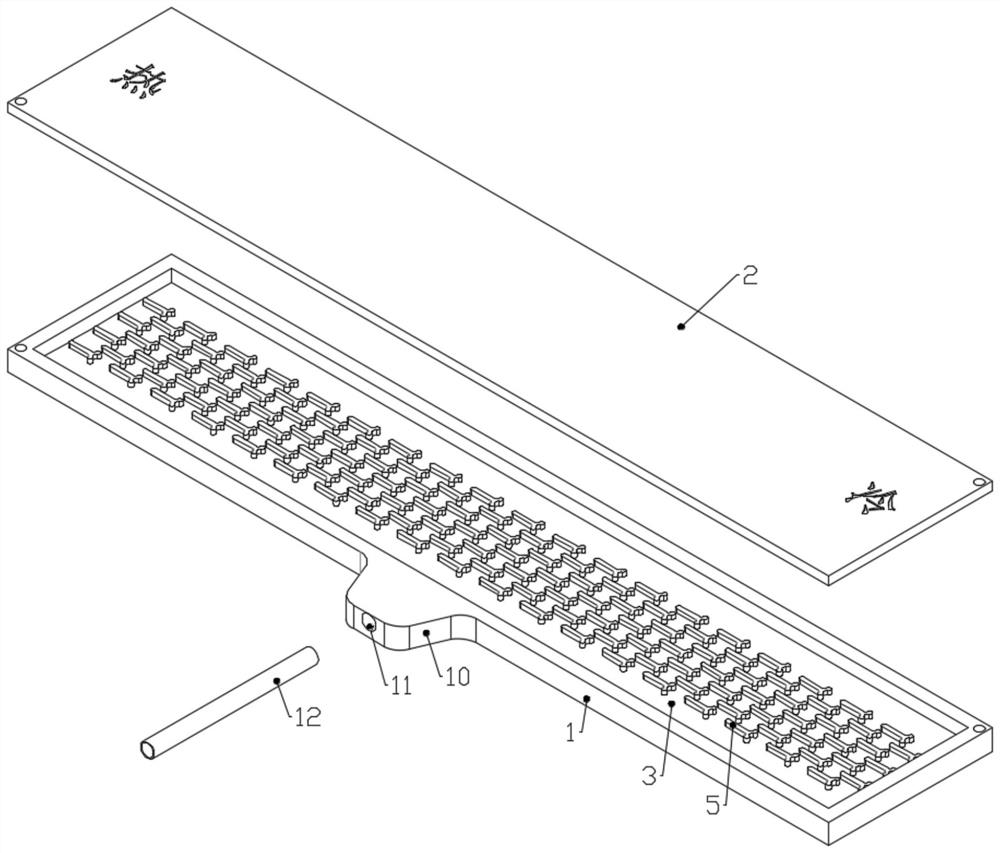

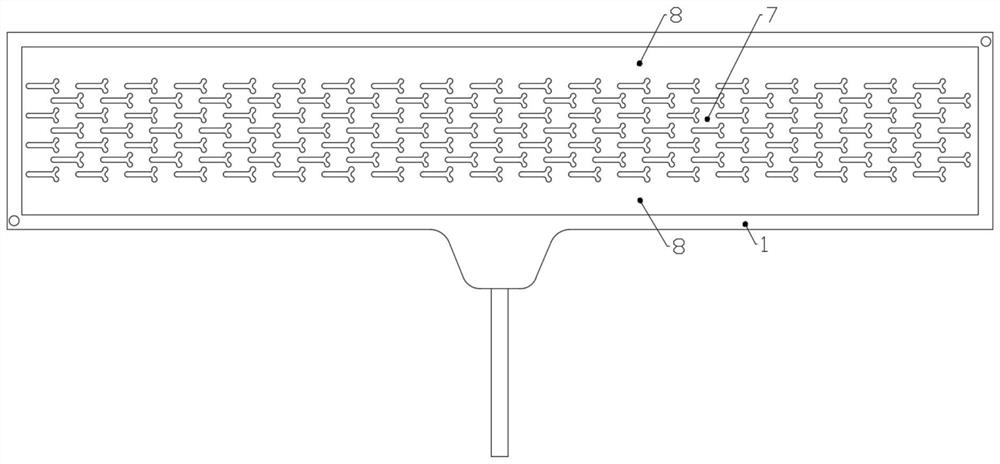

[0039] Such as Figure 1-Figure 4 As shown, the present invention provides a Y-shaped guide table liquid-absorbing core unidirectional heat transfer heat pipe, including a first heat transfer assembly 1 and a second heat transfer assembly 2, and the first heat transfer assembly 1 and / or the second heat transfer assembly A diversion groove 3 is opened on the component 2, and the sides with the diversion groove 3 of the first heat transfer component 1 and the second heat transfer component 2 are connected to each other to form a closed diversion chamber 4, the bottom surface of the diversion chamber 4 and A number of Y-shaped diversion platforms 5 in the same direction are evenly arranged on the top surface, and the diversion cavity 4 is filled with working fluid.

[0040] Specifically, the first heat transfer assembly 1 and the second heat transfer assembly 2 are parts with a certain length made of materials that are easy to conduct heat (such as metal). When in use, the first ...

Embodiment 2

[0053] The present invention also provides a processing method for the one-way heat transfer device of the Y-shaped flow guide table 5 liquid-absorbing core, comprising the following steps:

[0054] S1. Process the first heat transfer component 1 and the second heat transfer component 2, and process several Y-shaped uniform arrays with the same direction on the side of the first heat transfer component 1 and the second heat transfer component 2 forming the flow guide cavity 4 The deflector 5; S2. Process the liquid injection hole 9 and the installation hole 11 on the outer surface of the first heat transfer component 1; S3. Perform hydrophilic treatment on the Y-shaped deflector 5; S4. Connect the first heat transfer The component 1 and the second heat transfer component 2 form a diversion chamber 4, and the Y-shaped diversion platform 5 on the bottom surface of the diversion chamber 4 is aligned with the Y-shaped diversion platform 5 on the top surface; S5. Sealed with high-te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com