Sealing structure for enamel reaction kettle

A technology of enamel reaction kettle and sealing structure, applied in chemical/physical/physical-chemical stationary reactors, chemical/physical/physical-chemical processes, chemical instruments and methods, etc., can solve the problems of complex sealing structure and high cost, and achieve Good sealing, good corrosion resistance, and the effect of sealing guarantee

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

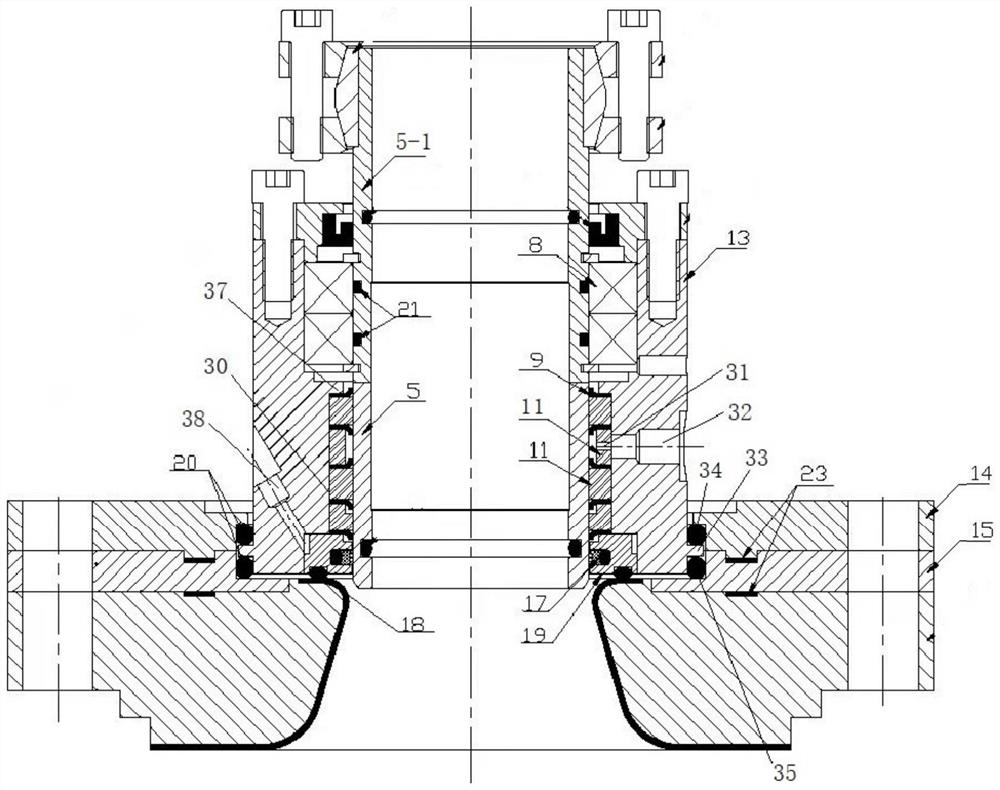

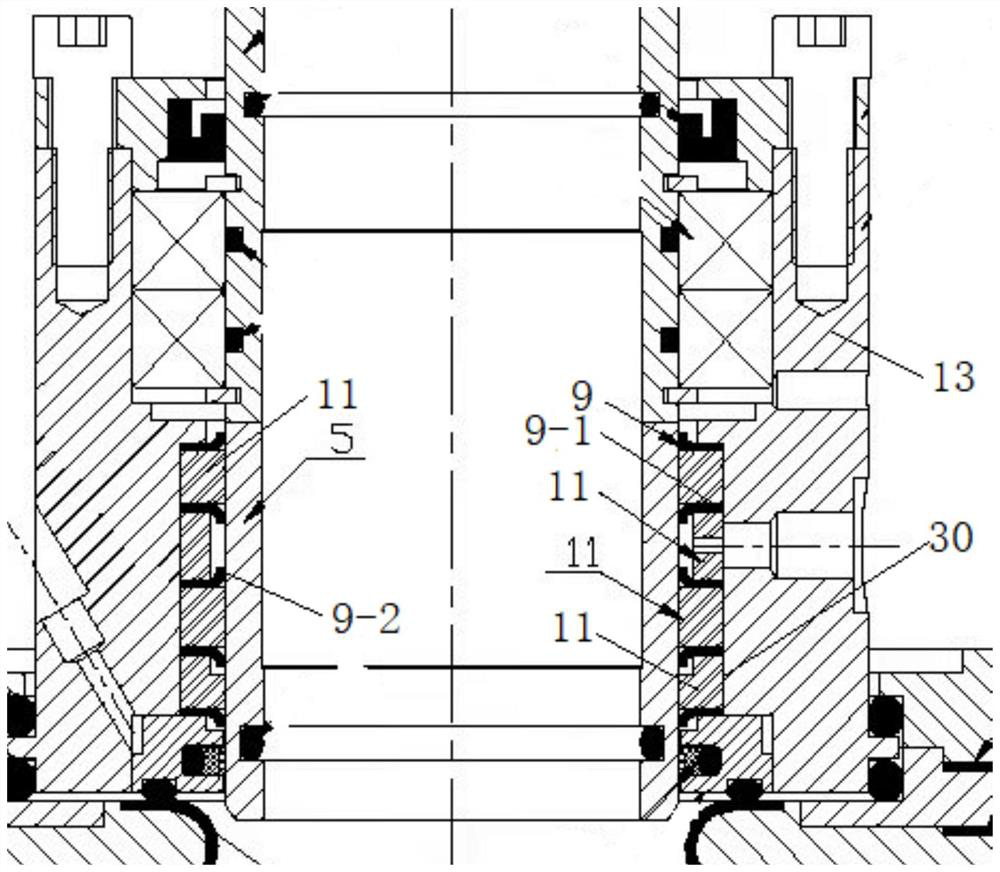

[0019] like Figure 1-2 , a sealing structure for an enamel reaction kettle in this embodiment, comprising a bearing housing 13 with a first through hole 30 opened at the bottom, a first shaft sleeve 5 is arranged on the inner side of the first through hole 30, and the first A shaft sleeve 5 is made of ceramic or silicon carbide, and four spaced back rings 11 are fitted and fixed in the first through hole 30, and elastic sealing lips are arranged between adjacent back rings 11. 9. The sealing lip 9 includes an annular body 9-1, the inner side of the annular body 9-1 is provided with a lip portion 9-2, and the annular body 9-1 is matched and fixed on the adjacent backing ring 11 Between the inner end surfaces, the lip portion 9-2 is in close contact with the outer side of the first bushing 5 and is curved in an arc shape.

[0020] Preferably, the sealing lip 9 is made of glass fiber, carbon fiber, carbon graphite, barium sulfate, and silicon dioxide added to tetrafluoroethylen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com