Cutting device for plywood processing

A cutting device, plywood technology, applied in the direction of wood processing appliances, manufacturing tools, sawing equipment, etc., to achieve the effect of easy contact and separation, and improve efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

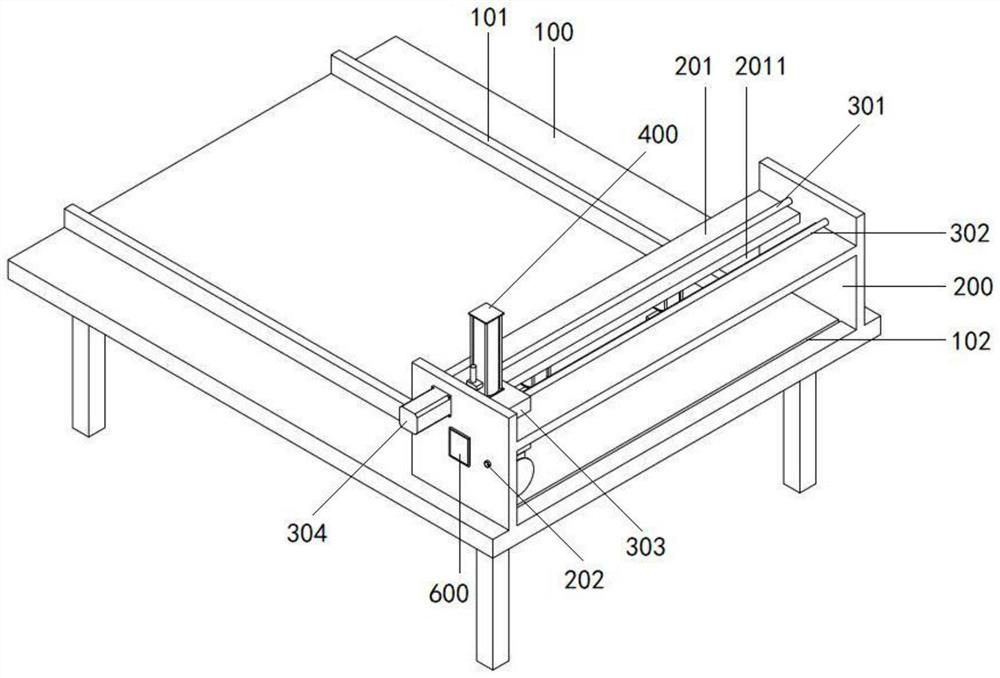

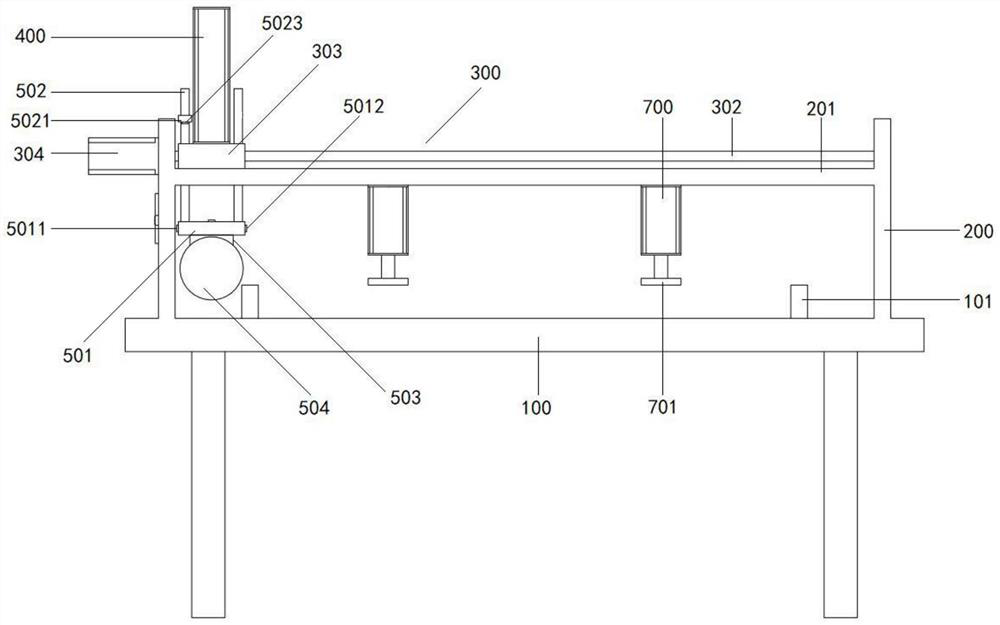

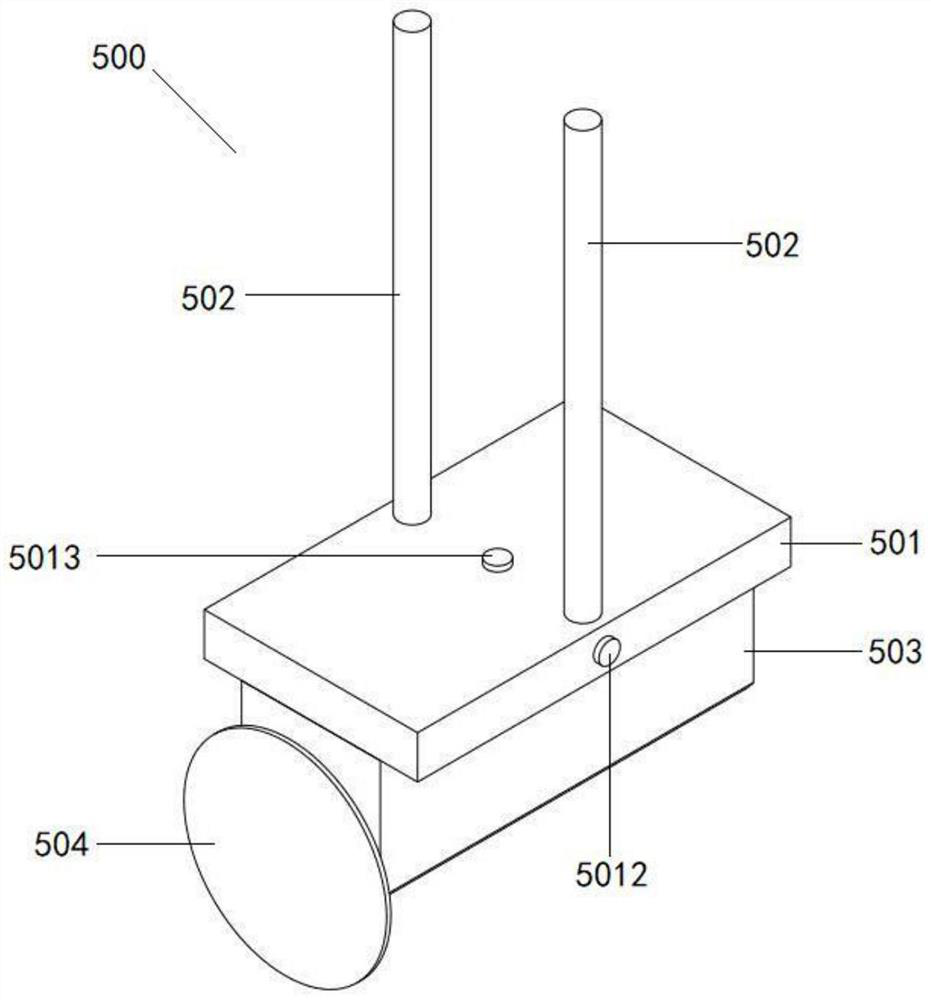

[0039] See attached Figure 1-4 , a cutting device for plywood processing, comprising:

[0040] The cutting table 100 is provided with two limiting plates 101 extending along its length direction at intervals on the cutting table 100 .

[0041] The support frame 200 is fixed on the front end of the cutting table 100, and the middle part of the support frame 200 is provided with a horizontal support plate 201;

[0042] The driving part 300 is arranged on the supporting frame 200 and is located above the supporting plate 201; specifically, the driving part 300 includes a driving screw 301, a balance bar 302, a sliding seat 303 and a driving motor 304, a driving screw 301 and a balancing bar 302 Set on the support frame 200 at intervals, wherein one end of the transmission screw 301 is rotatably connected to the support frame 200, and the other end passes through the support frame 200 and is rotatably connected with it; the two ends of the balance bar 302 are fixed on the suppor...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap