Mariculture tail water purification device

A purification device and mariculture technology, which is applied in the field of mariculture, can solve the problems of poor cleaning effect, easy damage to the filter plate, and shorten the service life of the filter plate, so as to achieve convenient collection and treatment, better purification effect, and faster shaking Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

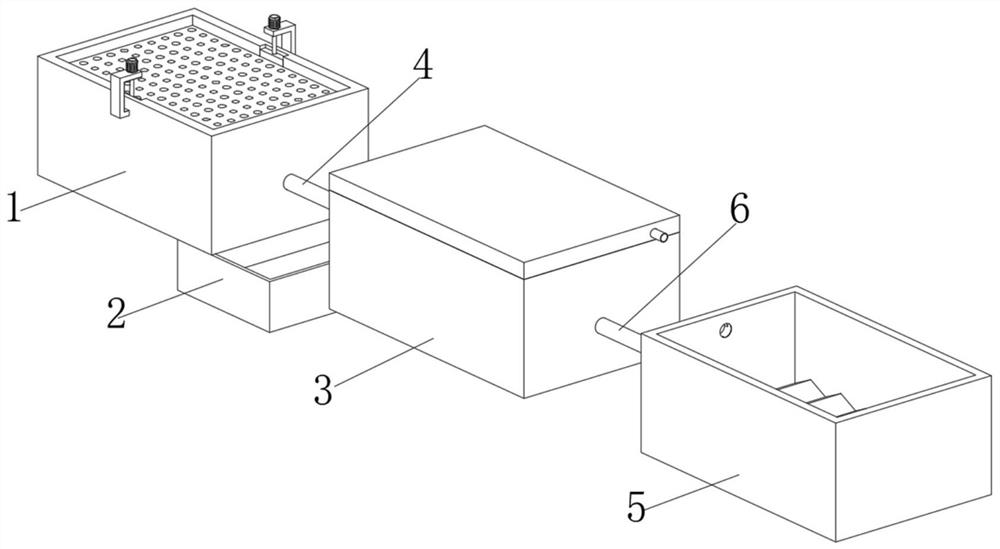

[0039] see figure 1 , the present invention provides a technical solution: a marine aquaculture tail water purification device, comprising a first purification device 1, a second purification device 3 and a neutralization device 5, the second purification device 3 is arranged on one side of the first purification device 1 side, the neutralization device 5 is arranged on the side of the second purification device 3 away from the first purification device 1, and a second connecting water pipe 4 is fixedly connected between the first purification device 1 and the outer wall of the second purification device 3, and the second purification A third connecting water pipe 6 is fixedly connected between the outer wall of the device 3 and the neutralization device 5, and a waste residue collection box 2 is arranged on the bottom outer wall of the first purification device 1, and the waste residue collection box 2 collects the waste residue.

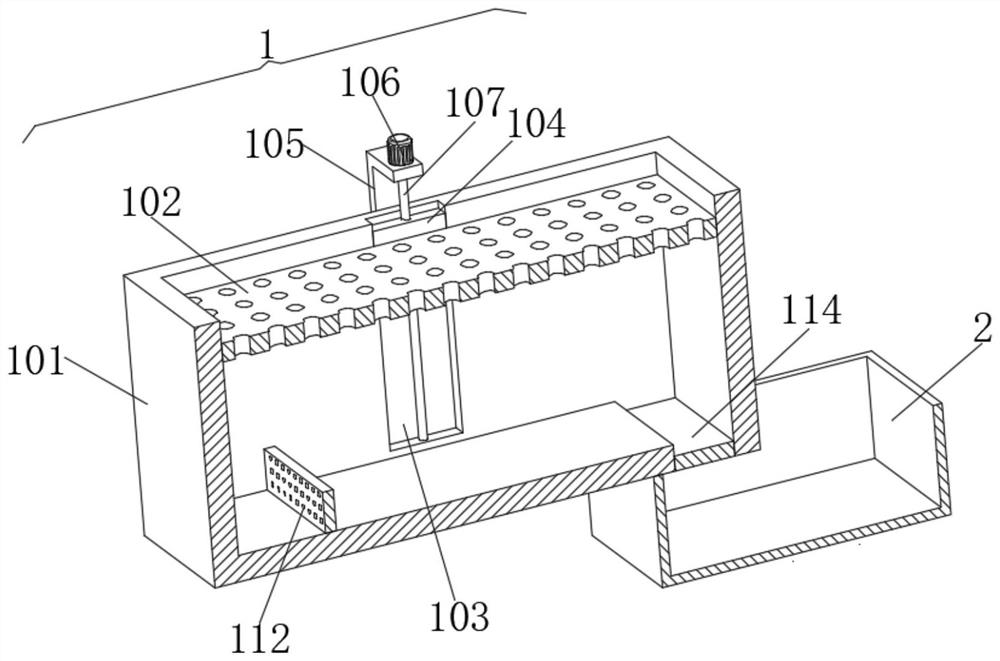

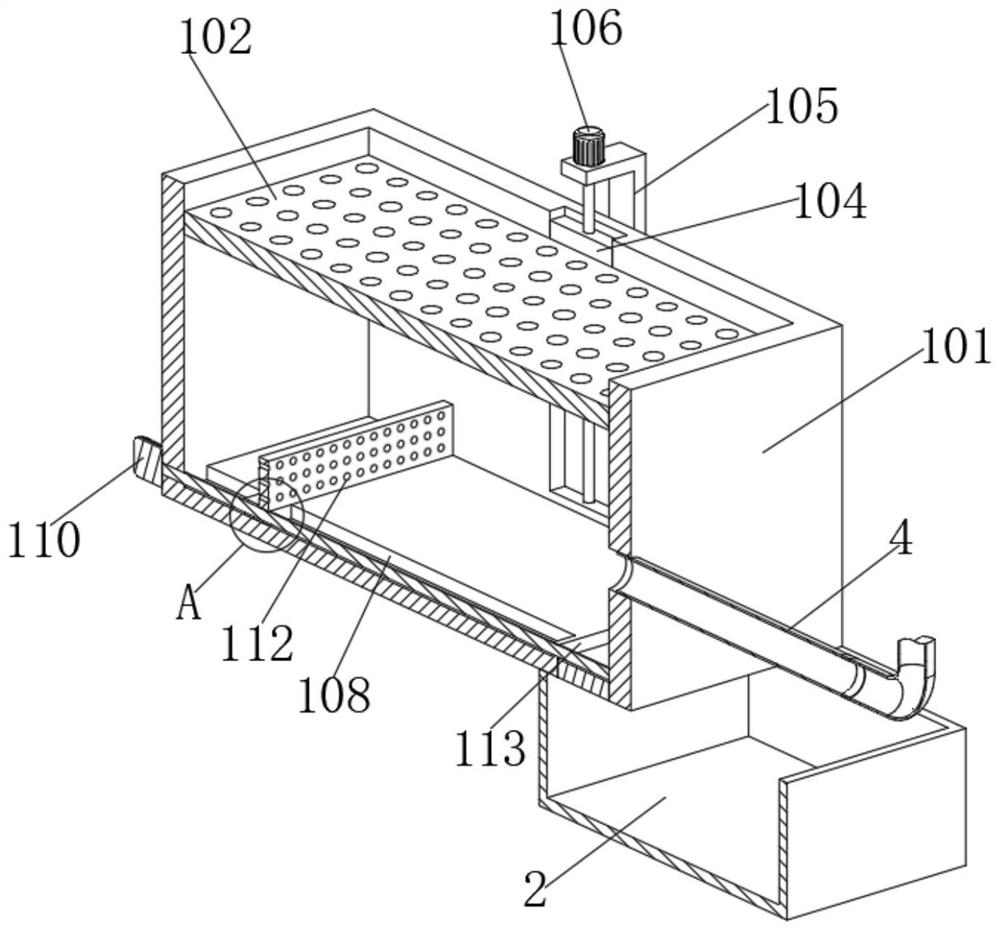

[0040] The specific structures and effects a...

Embodiment 2

[0044] see Figure 5-Figure 6 As shown, on the basis of Embodiment 1, the present invention provides a technical solution: the second purification device 3 includes a second purification box 301, the inner wall of the second purification box 301 is provided with a second filter screen 302, the first filter screen The mesh radius of 102 is greater than the mesh radius of the second filter screen 302, and the top outer wall of the second purification box 301 is movably connected with a case cover 303, and one side outer wall of the second purification box 301 is fixedly connected with a backwash water inlet pipe 304, and the box The top of the inner wall of the cover 303 is fixedly connected with a spray pipe 305, and the spray pipe 305 is distributed in a uniform linear array on the top of the tank cover 303. The outer wall of the spray pipe 305 is fixedly connected with a first connecting water pipe 306, and the backwash water inlet pipe 304 and the spray pipe The inner wall o...

Embodiment 3

[0046] see Figure 7-Figure 8 As shown, on the basis of Embodiment 1 and Embodiment 2, the present invention provides a technical solution: the neutralization device 5 includes a reaction box 501, the bottom of the inner wall of the reaction box 501 is fixedly connected with a spring 502, and the springs 502 are evenly distributed in an array The bottom of the reaction box 501, the inner wall of the reaction box 501 is movably connected with a vibrating plate 503, and the end of the spring 502 away from the reaction box 501 is fixedly connected with the bottom outer wall of the vibrating plate 503. After being purified by the second purification device 3, the aquaculture tail water passes through the first 2. Connect the water pipe 4 into the neutralization device 5, add chemical reagents in the reaction box 501 in advance, the impact of the water flow makes the vibrating plate 503 shake, and the setting of the spring 502 accelerates the shaking of the vibrating plate 503, so t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com