Method for operating exhaust gas recirculation type gas turbine

An exhaust gas recirculation and gas turbine technology, which is applied to gas turbine devices, mechanical equipment, combined engines, etc., can solve the problems of not disclosing the high-efficiency part-load operating range, not describing the operation information, and reducing the efficiency of the power station. Reduced efficiency, reduced pressure loss, and improved thermal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

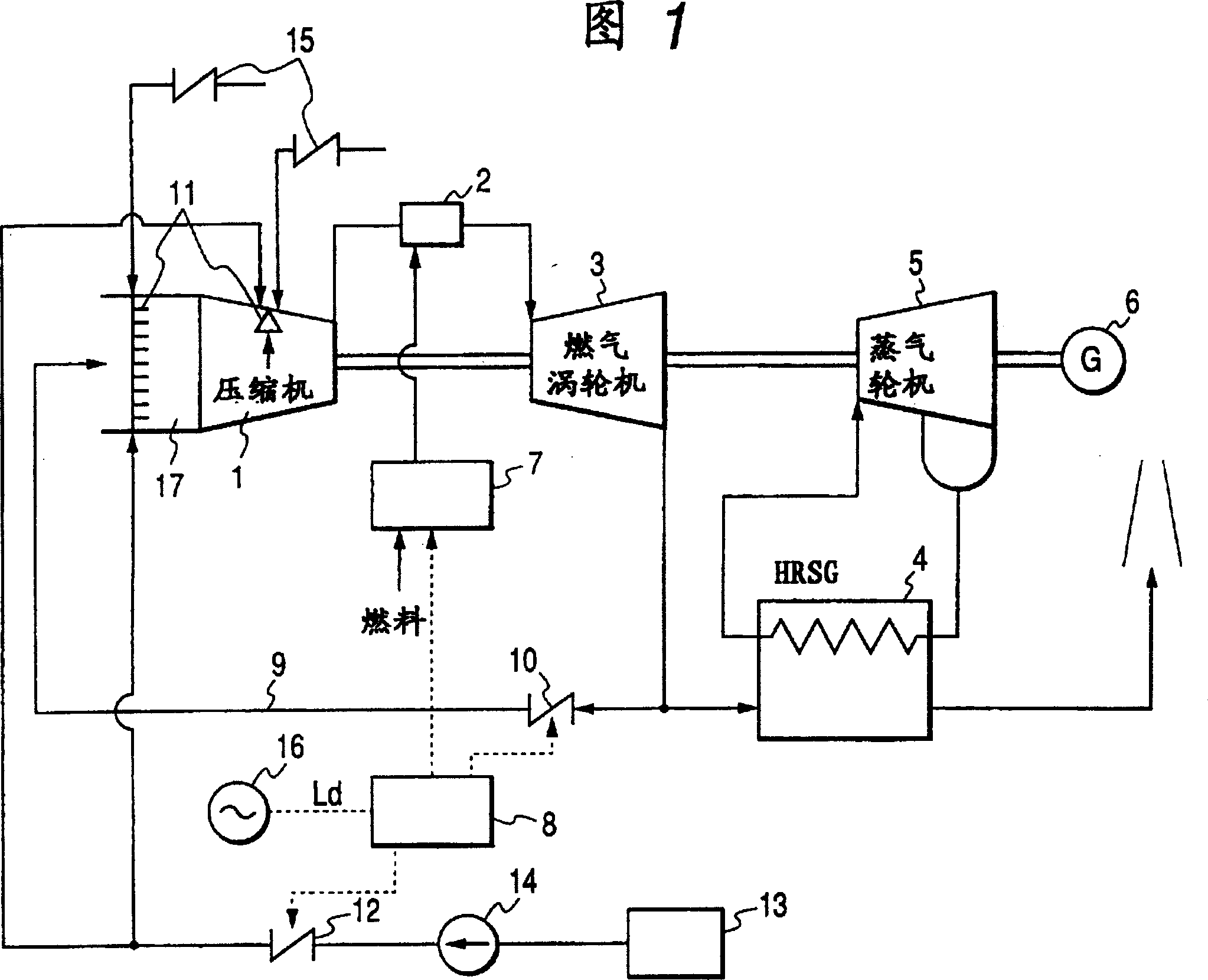

[0047] Figure 1 shows a first embodiment of the invention. The exhaust gas recirculation combined power plant with a gas turbine inlet water injection system includes: a compressor (compressor) 1 for sucking in and compressing air, a combustor 2 for mixing and burning compressed air and fuel; a a gas turbine 3 driven by combustion gas from the combustion chamber 2; a waste heat recovery boiler 4 for recovering gas turbine waste heat exhausted from the gas turbine 3 to generate steam by heat exchange with supplied water; a steam-driven a steam turbine 5, the steam being generated by a gas turbine waste heat recovery boiler 4; a generator 6 connected to the steam turbine 5; a recirculation device (pipe) 9 comprising a part for taking out a part of the exhaust gas of the gas turbine 3 and A recirculation path which recirculates it to the inlet of a compressor; and a recirculation amount control device (exhaust gas recirculation amount regulating valve) 10 for controlling the reci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com