High-voltage high-precision large-current piezoelectric ceramic constant-current driving circuit

A piezoelectric ceramic, constant current drive technology, applied in the direction of adjusting electrical variables, instruments, control/regulating systems, etc., can solve problems such as slow dynamic response speed, reduce static power consumption, improve dynamic response characteristics, and widely popularize The effect of applying value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0079] The present invention provides a high-voltage, high-precision, and high-current piezoelectric ceramic constant-current drive circuit, and its specific implementation method is:

[0080] The high-voltage, high-precision, and high-current piezoelectric ceramic constant-current drive circuit includes:

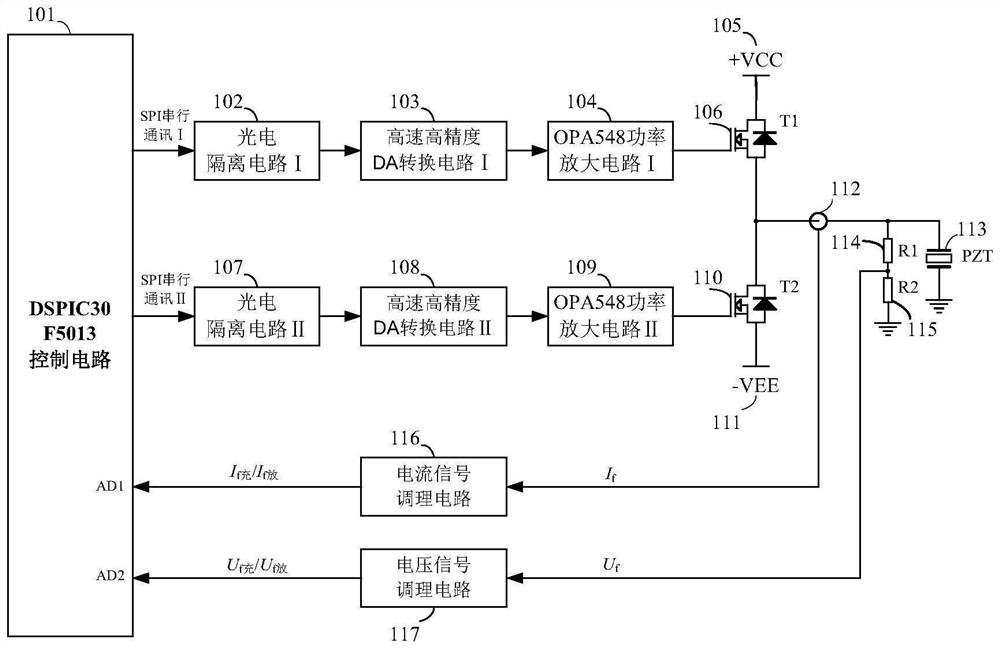

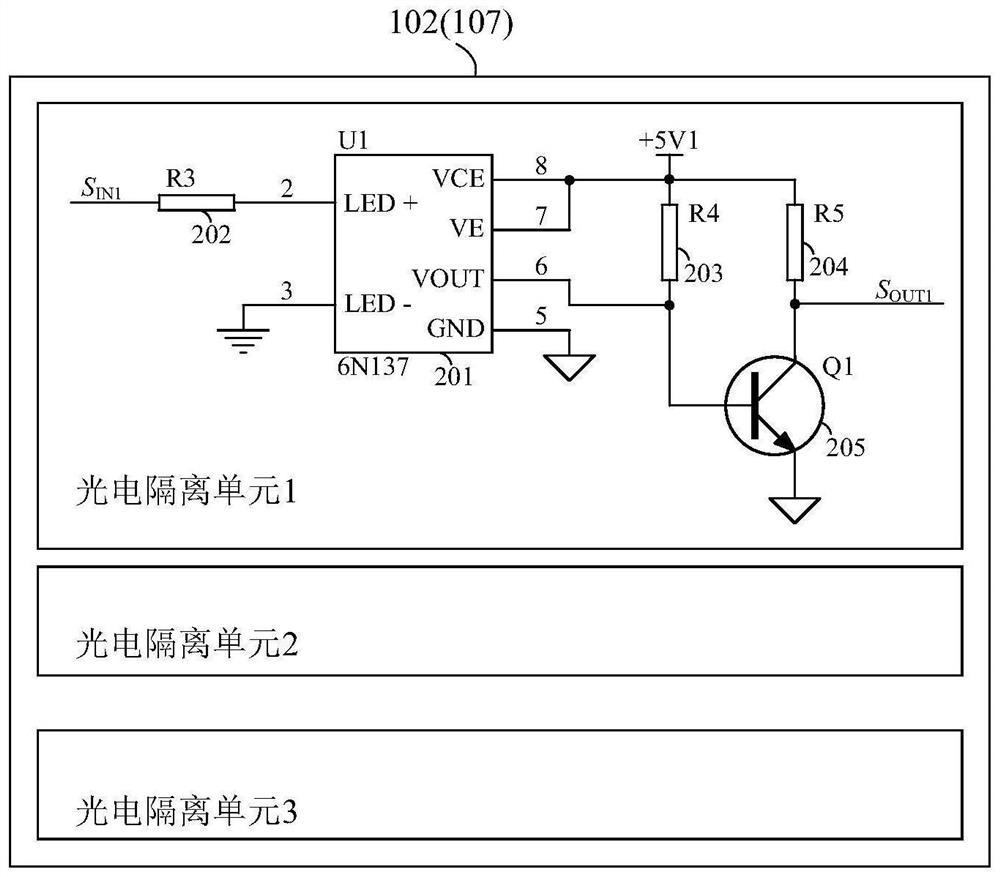

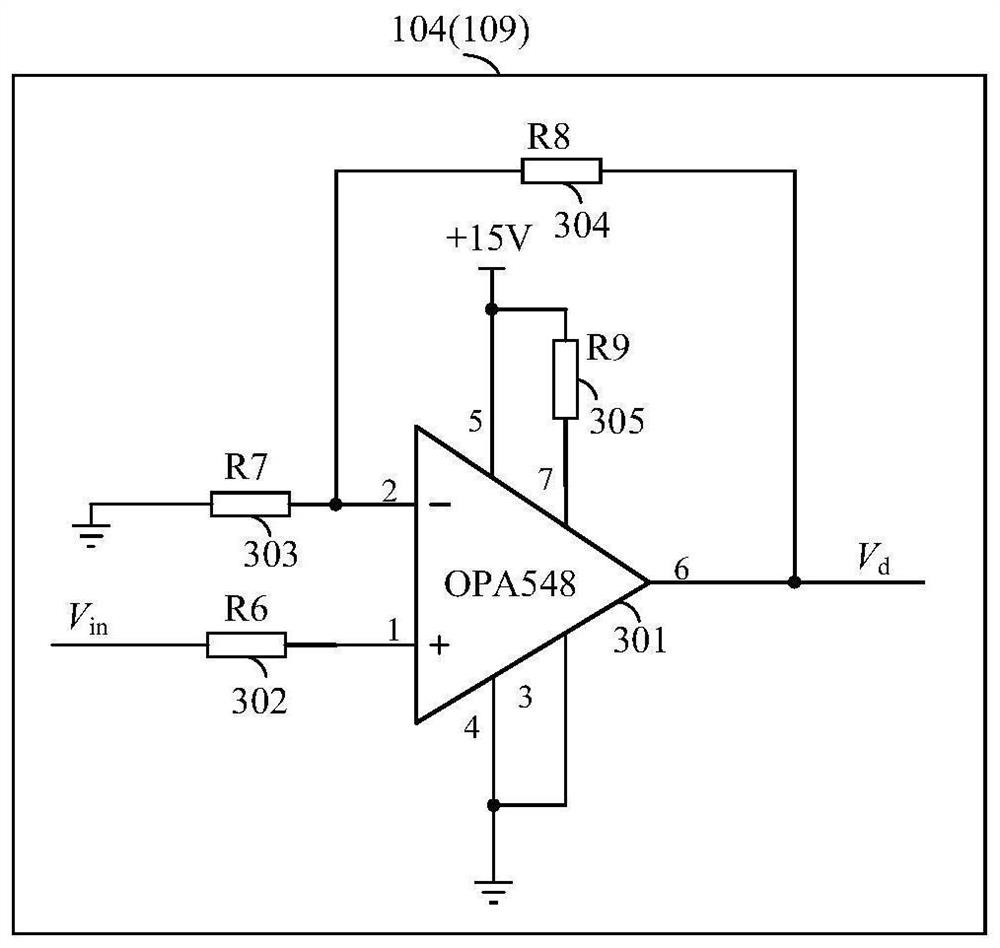

[0081] see figure 1As shown, DSPIC30F5013 control circuit (101), photoelectric isolation circuit Ⅰ (102), high-speed high-precision DA conversion circuit Ⅰ (103), OPA548 power amplifier circuit Ⅰ (104), piezoelectric ceramic charging drive power supply + VCC (105), MOSFET power tube T1 (106), photoelectric isolation circuit II (107), high-speed high-precision DA conversion circuit II (108), OPA548 power amplifier circuit II (109), MOSFET power tube T2 (110), piezoelectric ceramic discharge drive power supply -VEE (111), current sensor (112), piezoelectric ceramics (113), voltage divider resistor R1 (114), sampling resistor R2 (115), current signal conditioning circuit (116...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com