Transient analysis method for reworking system under customized production

A production system and analysis method technology, applied in the direction of design optimization/simulation, instruments, complex mathematical operations, etc., can solve problems such as the inapplicability of steady-state analysis methods, and achieve fast operation speed, simplified performance evaluation problems, and no random errors Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0119] In order to make the purpose, technical solution and advantages of the present invention clearer, the content of the invention will be further described below in conjunction with the accompanying drawings and examples.

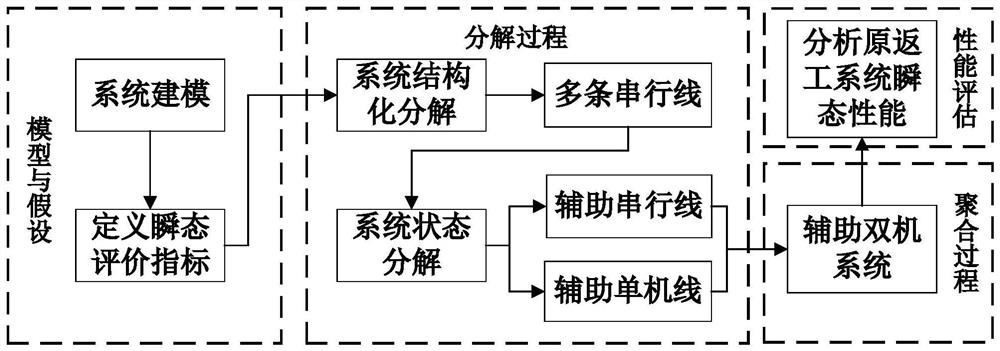

[0120] like figure 1 As shown, the transient performance analysis method of the rework production system based on unreliable machines, limited buffer zone and customized production disclosed in this embodiment, the specific implementation steps are as follows:

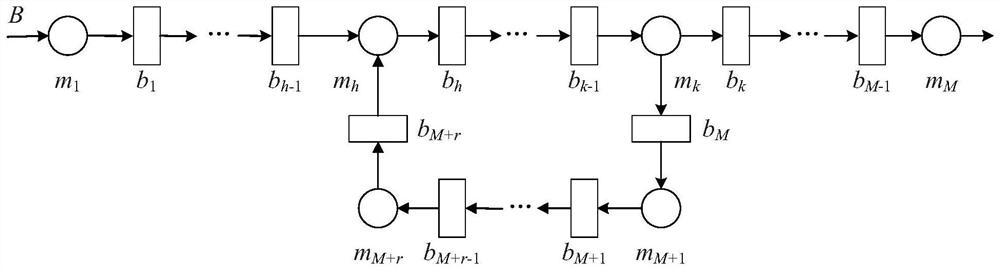

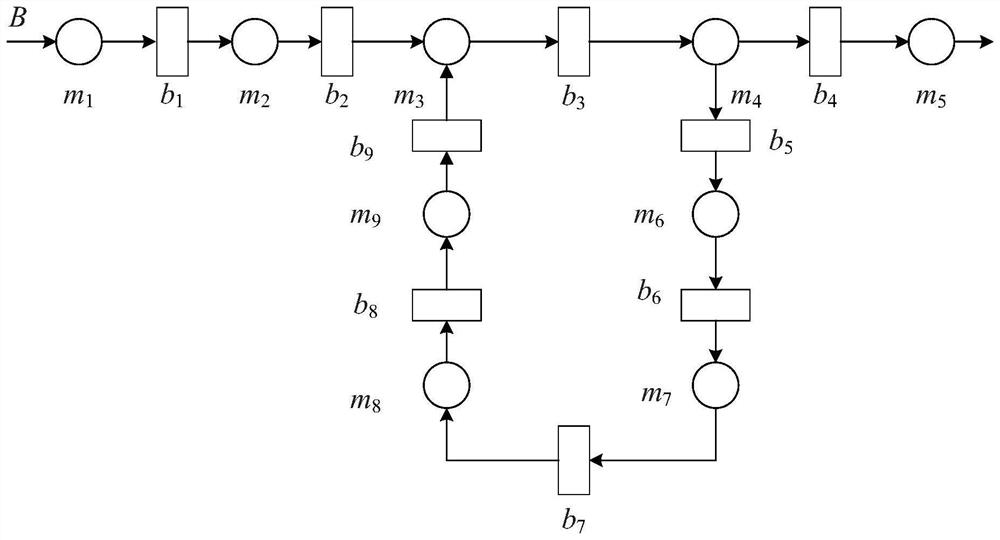

[0121] Step 1: Model a rework production system based on unreliable machines, finite buffers, and customized production, which consists of a main line and a rework cycle, such as figure 2 shown. The modeling process includes: determining the parameters of the rework system, determining the mathematical description of the production state, and determining the mathematical description of the rework operation. The parameters that need to be determined during the modeling process are: number of m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com