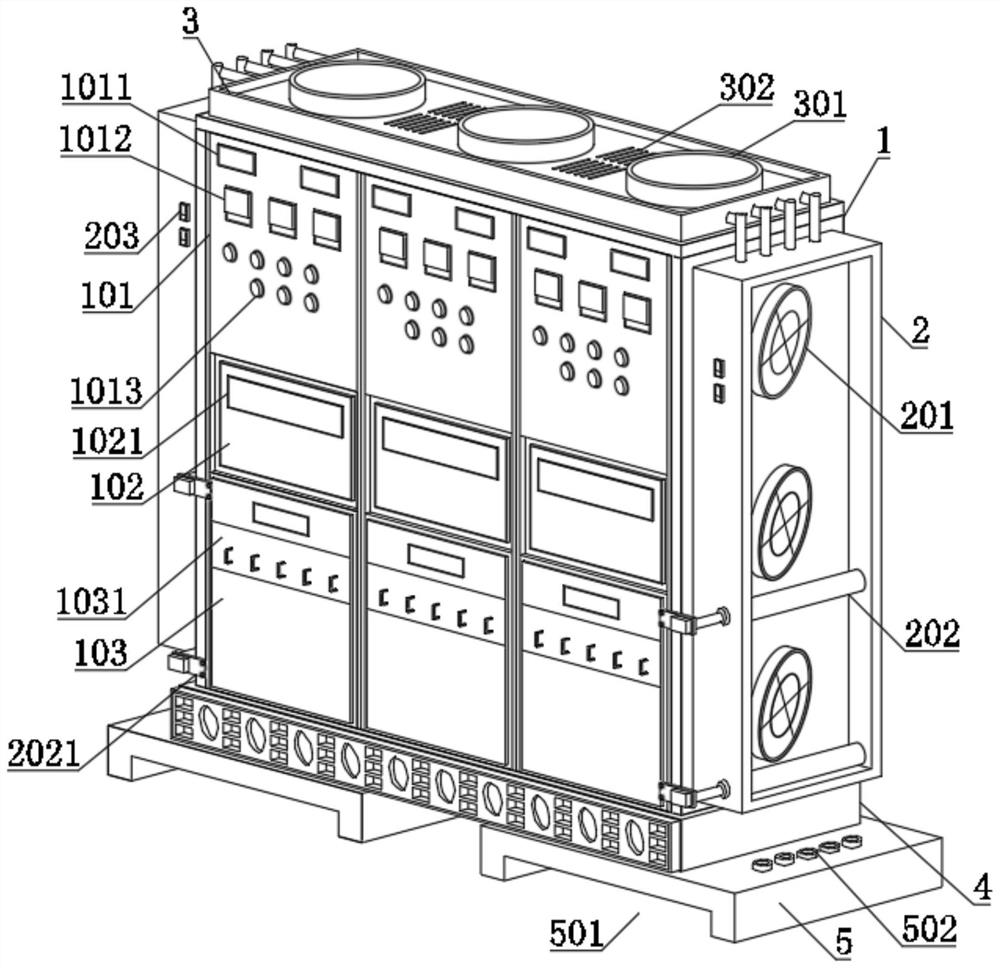

Low-voltage switch equipment with active cooling assembly and implementation method of low-voltage switch equipment

An active cooling and switchgear technology, applied in the setting of switchgear, switchgear, pull-out switchgear, etc., can solve the problems of low-voltage switchgear internal heat cannot be discharged in time, poor functionality of switchgear, poor cooling and heat dissipation effects, etc. , to achieve the effect of being conducive to long-term work, improving service life and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

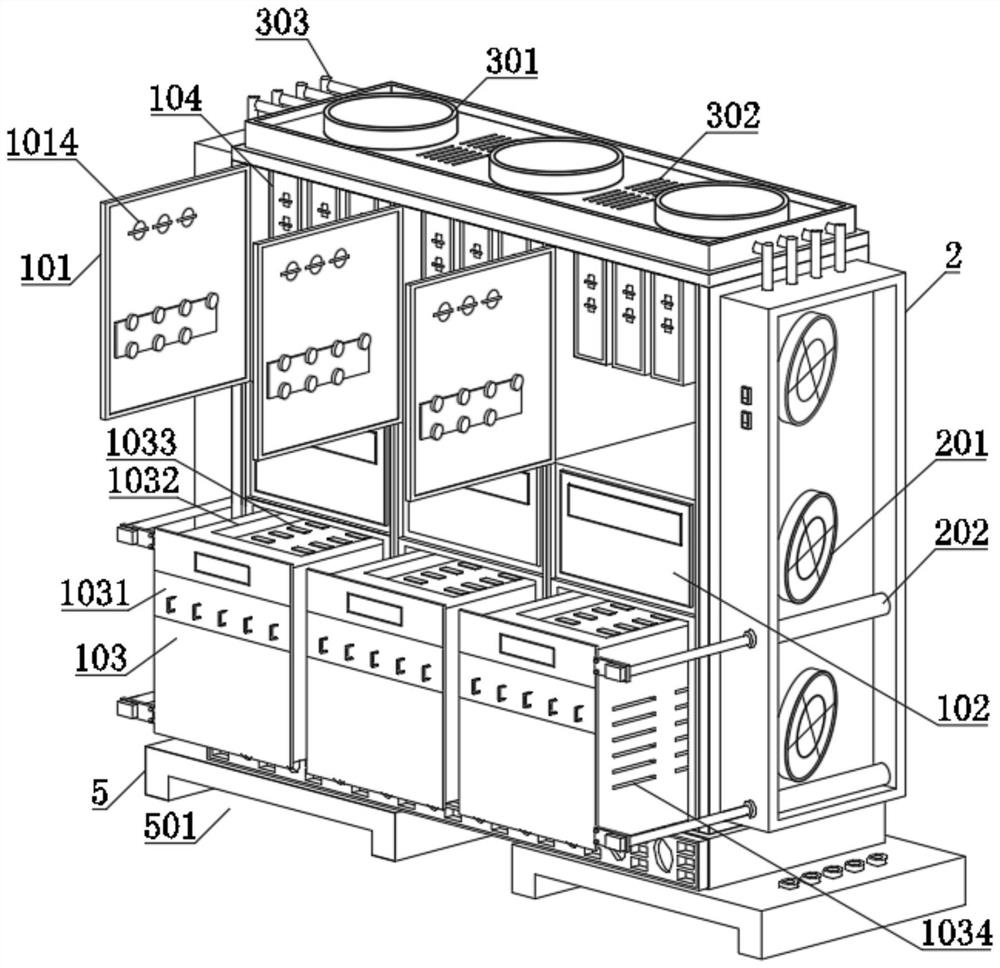

[0045] A method for implementing a low-voltage switchgear with active cooling components, comprising the steps of:

[0046] Step 1: Lead the incoming cable 505 into the wire inlet 502, pass through the current detection sensor 503 and the protective wire sleeve 504 to extend the inside of the switchgear main body 1, and connect with the vacuum switch 1033, and the incoming wire can be adjusted through the wire inlet 502 The angular position of the cable 505 reduces the wear and tear of the incoming cable 505 and improves the service life;

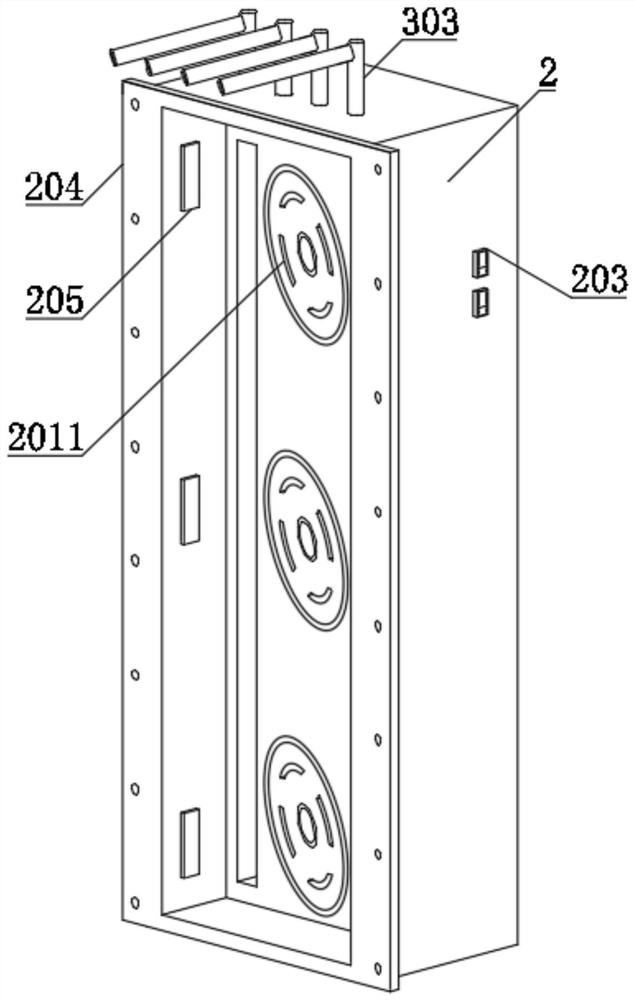

[0047] Step 2: Connect the low-voltage circuit equipment through the drawer-type vacuum circuit breaker 103 and the cable busbar installation box 104, adjust the vacuum switch 1033 and the switch button 1013 to control the power switch, and adjust the drawer-type vacuum circuit breaker by telescopic electric cylinder 202 during maintenance and overhaul The position of 103 is convenient for operation, and can maintain the sealing effect of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com