Cooling device capable of achieving uniform jet flow for hot-rolled coiled plate and method of cooling device

A technology for cooling devices and hot-rolled coils, applied in workpiece cooling devices, metal rolling, metal rolling, etc., can solve the problems of low cooling efficiency, insufficient jet flow uniformity, and easy temperature rise, so as to speed up cooling, Improve visibility and speed up the effect of dispersing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

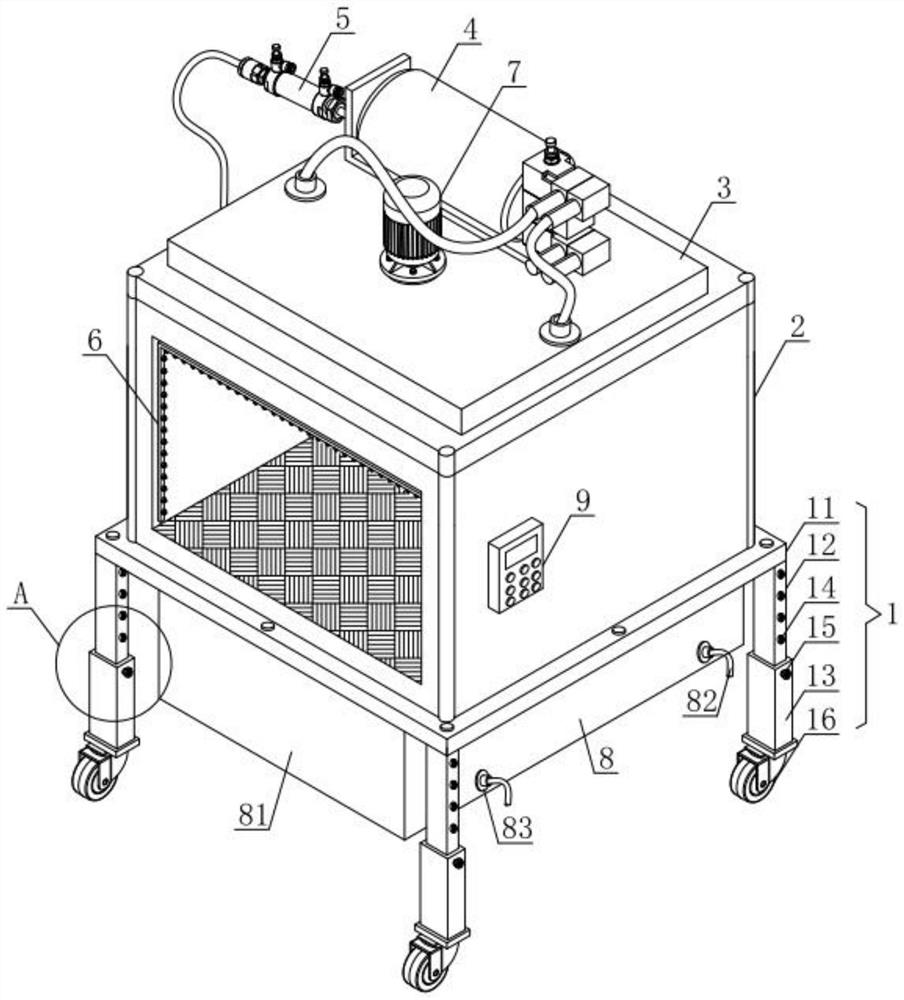

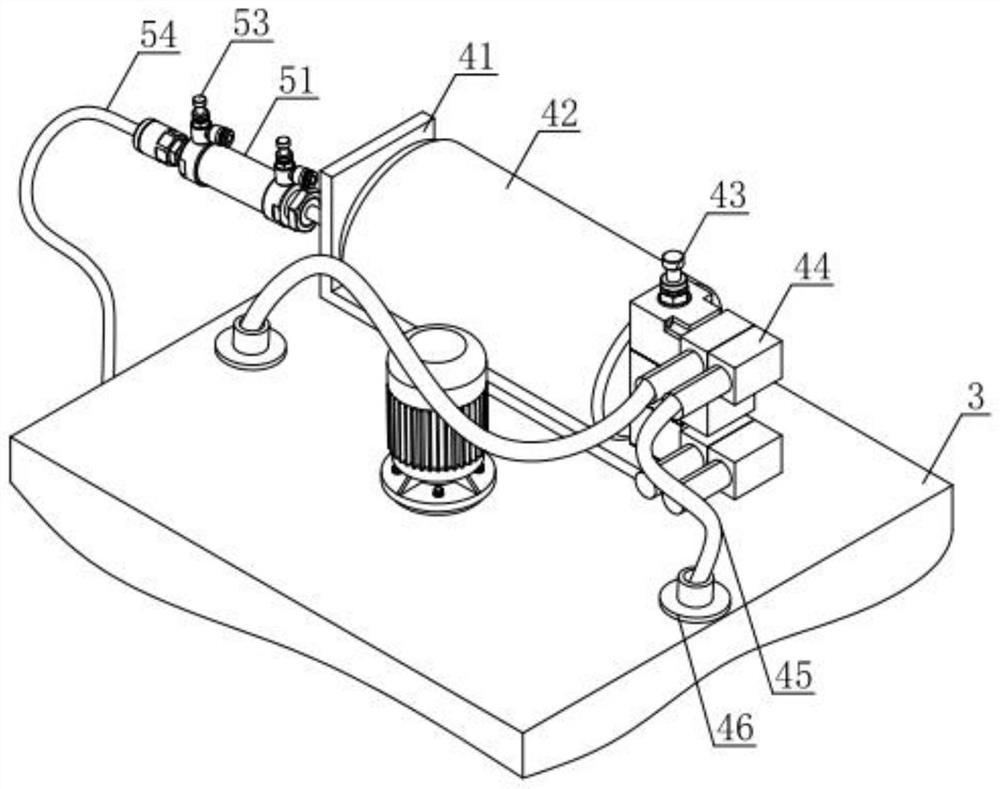

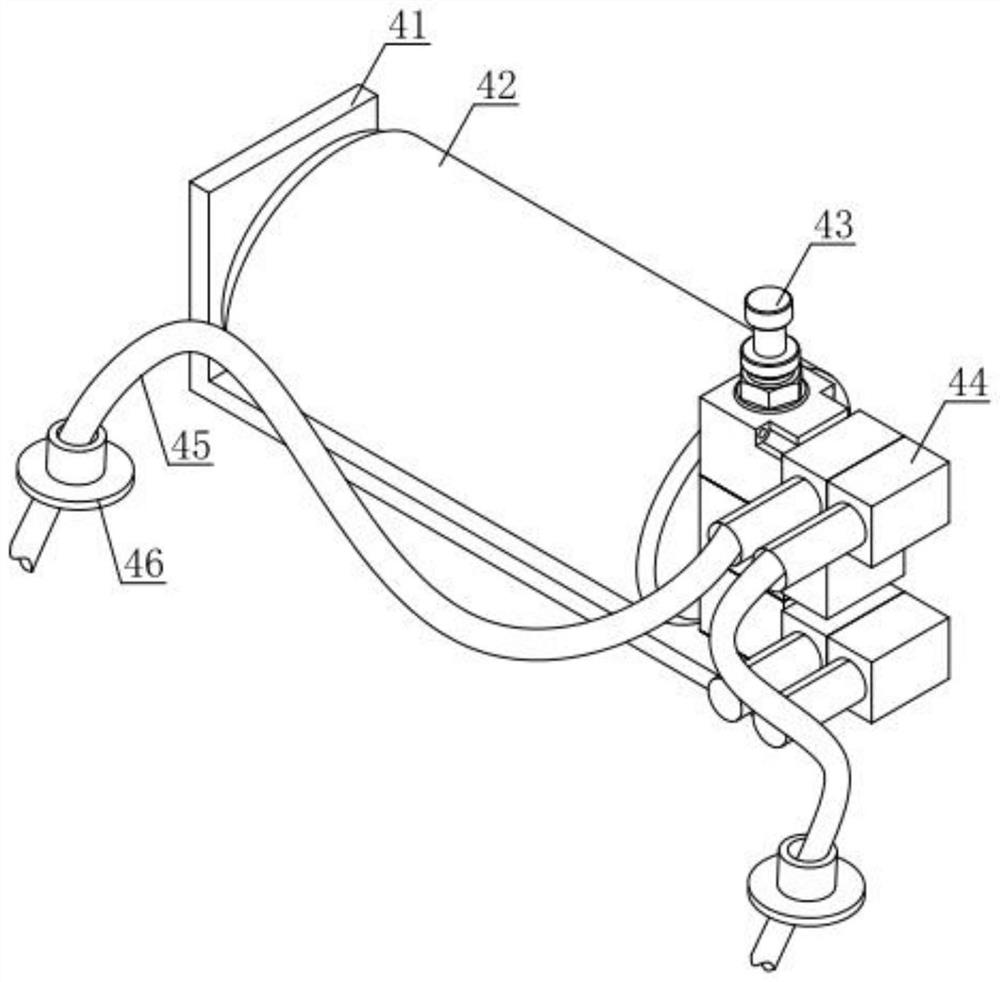

[0036] refer to figure 1, a uniform jet cooling device and method for hot-rolled coils, including a support base 1, the support base 1 includes a support frame 11, an adjustment A rod 12, an adjustment B rod 13, a hole 14, a screw 15 and a roller 16 , the center of the surface of the support frame 11 is hollow, which is convenient for the water after spraying to flow into the bottom. The surroundings of the bottom of the support frame 11 are connected with the top of the adjustment A rod 12, and the bottom of the adjustment A rod 12 is sleeved on the adjustment B rod 13 Inside, one side of the surface of the adjustment A rod 12 is provided with a hole 14, and one side of the surface of the adjustment B rod 13 is provided with a screw 15, and the screw 15 is inserted into the inside of the gap 14 for detachable connection, and the bottom of the adjustment B rod 13 Connected with the roller 16; the surface of the support seat 1 is provided with a cooling chamber 2, before use, t...

Embodiment approach

[0040] In order to better demonstrate the implementation method that can realize the cooling of a hot-rolled coil with a uniform jet flow, the steps are as follows:

[0041] S1: The support seat 1 moves the cooling cabin 2 to the processing place of the hot-rolled coil through the roller 16 at the bottom, and the adjustment A rod 12 is inserted in the inside of the adjustment B rod 13, and the position of the notch 14 and the screw 15 is adjusted. After reaching the appropriate height, lock and fix it with the knob screw 15;

[0042] S2: Connect the water inlet pipe 54 at one end of the condensation pipe 5 with the external water source, and connect the pipe body 51 with the external control equipment through the controller 9 to start the switch 53. After the external water source enters the pipe body 51, the inside of the pipe body 51 uses heat The principle of exchange makes the liquid flow through the inner tube and condense to achieve a greater cooling effect, and finally ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com