Automatic quantitative nucleating agent adding system of automatic casting machine

An inoculant and casting machine technology, which is applied in the field of automatic quantitative addition system of inoculant for automatic casting machines, can solve the problems of cumbersome production arrangements, potential safety hazards, time-consuming and labor-intensive adjustment of the opening of the pneumatic gate, etc., and achieve excellent safety performance and reduce Labor intensity, the effect of improving pouring quality and production arrangement efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

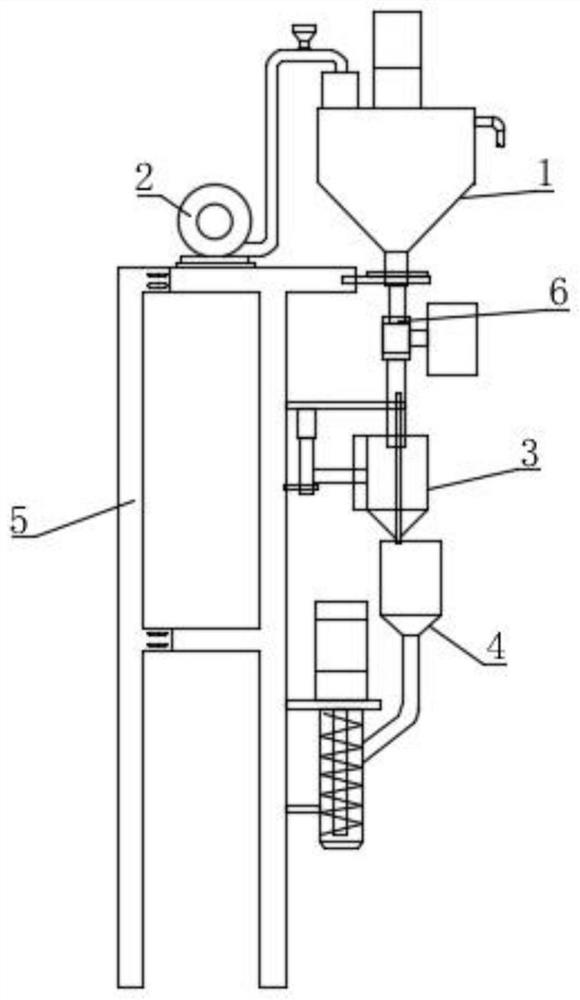

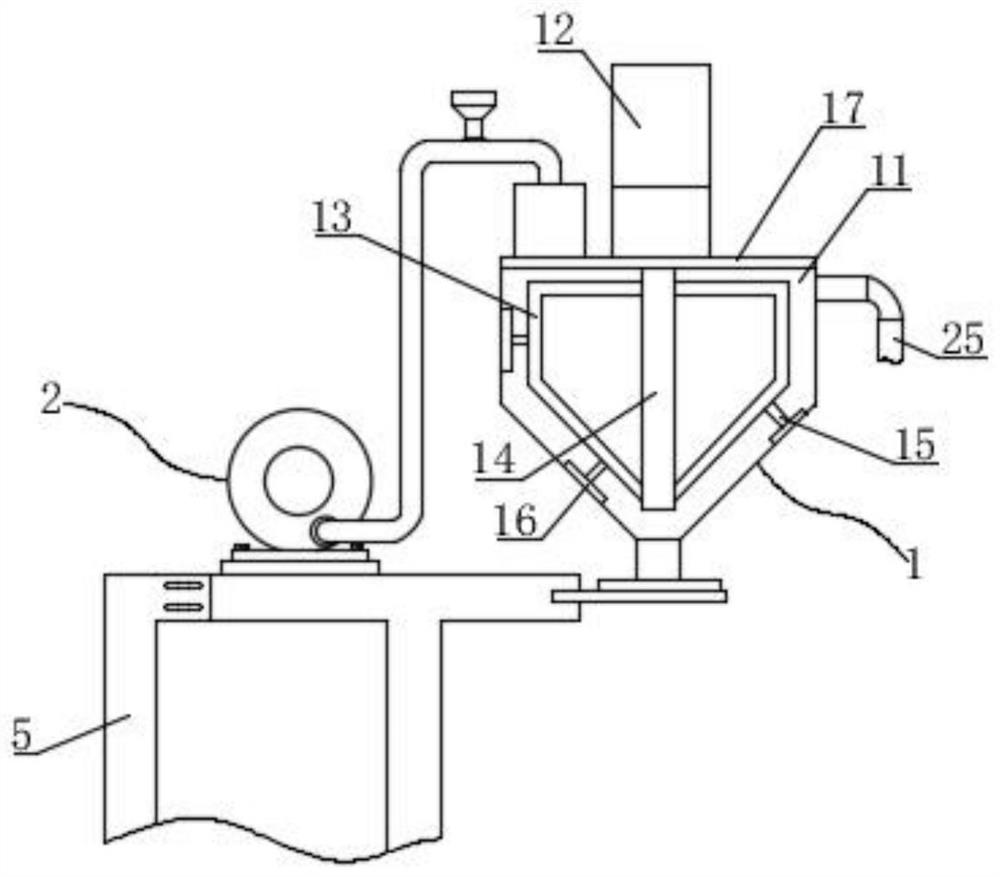

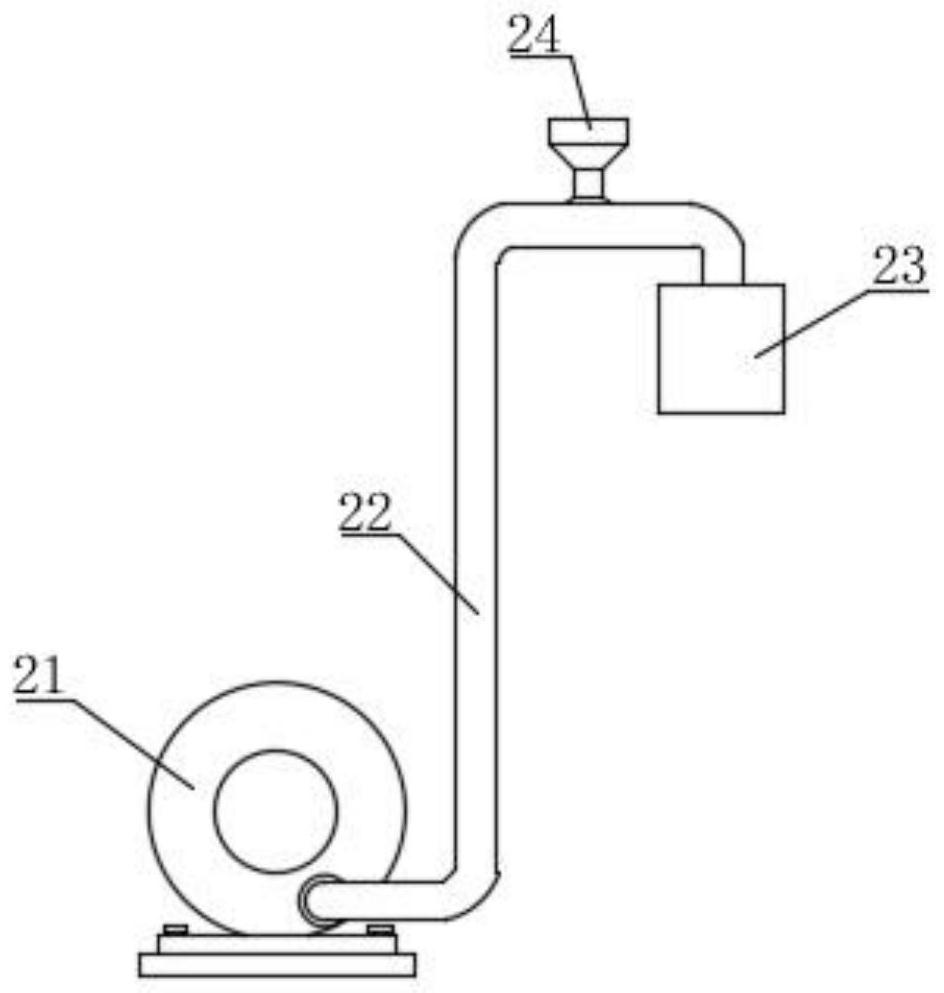

[0047] like Figure 1-6 As shown, a system for automatic quantitative addition of an inoculant for an automatic casting machine proposed by the present invention includes a material storage mechanism 1 and a control system, and the control system includes a control cabinet (not shown in the figure, which plays a control role) and is provided with a control panel , the material storage mechanism 1 is installed on the top of the frame 5, the material storage mechanism 1 includes a storage hopper 11, the storage hopper 11 is fixedly installed on the frame 5 by bolts, and a material level sensor is arranged in the storage hopper 11, and the material level sensor is used for controlling The material level of the inoculant in the storage hopper 11 is monitored, and a cover plate 17 is installed on the top of the storage hopper 11, a stirring shaft 14 is installed in rotation in the storage hopper 11, and the stirring motor 12 is fixedly installed on the cover plate 17 through a motor...

Embodiment 2

[0053] like figure 1 and Figure 5 As shown, the difference between this embodiment and Embodiment 1 is that the incubating mechanism 4 includes a receiving hopper 41, and the frame 5 is fixed with a horizontally arranged mounting plate 45 by bolts, and the top of the mounting plate 45 is fixedly installed with a motor base. Incubate the motor 44, the barrel 43 is vertically arranged and fixedly installed on the bottom of the mounting plate 45 by bolts, and the bottom of the barrel 43 is equipped with a disperser 47, the feeding shaft 46 is vertically arranged in the barrel 43, and the inoculation motor 44 The output end of the feeder shaft 46 is connected to the feed shaft 46 through a reducer and a coupling. The hopper 41 is located below the weighing hopper 301. A connecting pipe 42 is installed at the bottom of the hopper 41, and the end of the connecting pipe 42 away from the hopper 41 is downward. Connect with the gun barrel 43;

[0054] When the discharge is finished,...

Embodiment 3

[0056] The difference between this embodiment and Embodiment 1 and Embodiment 2 is that the running speed of the inoculation motor 44 is determined by the casting time input in advance, so as to ensure that all inoculants of this type pass through the disperser 47 when the inoculant is cast. Scatter evenly into the chute (not shown in the figure), and enter the mold through the junction of the chute outlet and the molten iron head to achieve the best effect of inoculation with the flow. Since weighing is faster than casting, it will be faster than casting. The casting is completed one type ahead of time, so at the end of the casting, since the weighing mechanism 3 has not obtained the weight parameter of the inoculant for the next type, there will be no weighing action, and the action of the incubating mechanism 4 is one type and one clear, so After the last type of casting is completed, except for the inoculant in the storage hopper 11 and the stirring structure in the storage...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com