General thermal design structure of satellite deck

A general-purpose, thermal design technology, applied in the direction of the living conditions control device of the spacecraft, can solve the problems of poor thermal design of the satellite, and achieve the effect of improving the thermal environment adaptability, high reliability and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

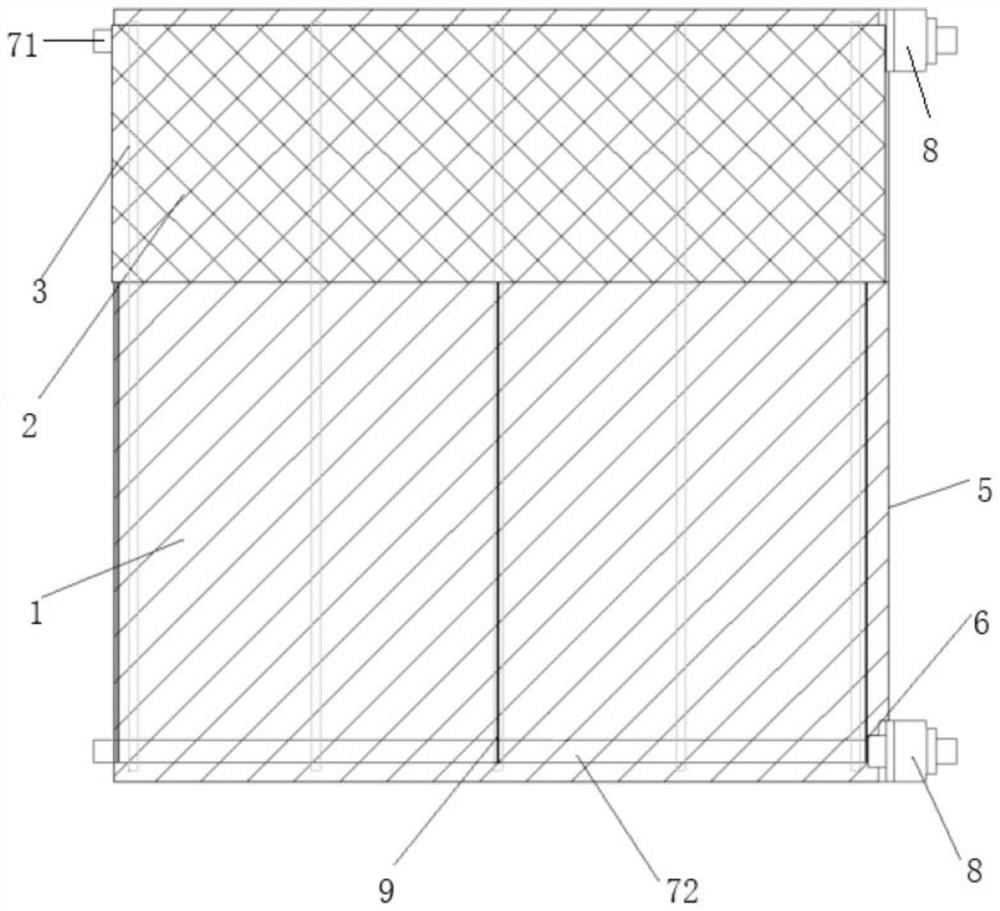

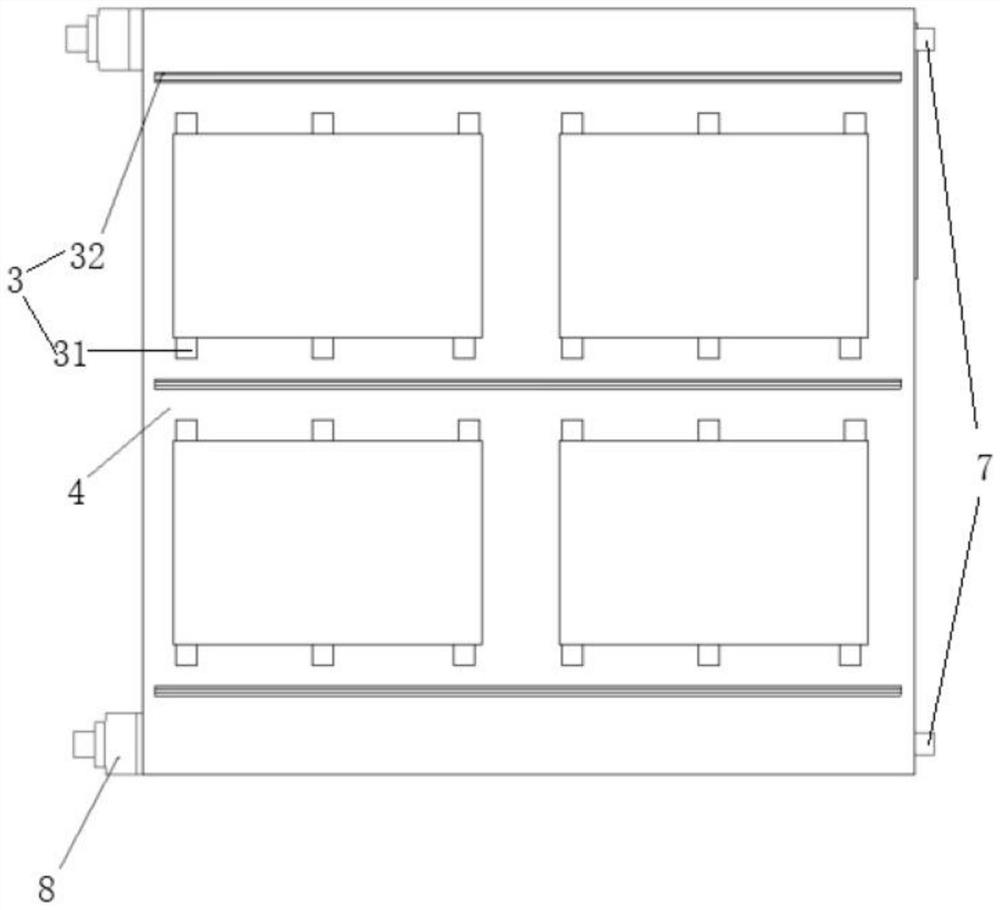

[0036] A general thermal design structure of satellite deck, including KS-ZA white paint layer 1, multi-layer heat insulation component 2, heat pipe network 3, black paint layer 4, aluminum honeycomb deck 5 and rotating mechanism 6, heat pipe network 3 is connected On the aluminum honeycomb deck 5, the inner surface of the aluminum honeycomb deck 5 and the outer surface of the stand-alone unit are sprayed with a black paint layer 4, and the stand-alone unit and the deck (with pre-buried holes in the board) are connected by screws, and the stand-alone unit is used to realize satellite sub-systems and load function; the multi-layer heat insulation component 2 is connected to the outer surface of the aluminum honeycomb cabin panel 5 through the rotating structure 6, and the outer surface of the aluminum honeycomb cabin panel 5 is sprayed with a KS-ZA white paint layer 1. Preferably, the aluminum honeycomb cabin panel 5 is hot-pressed from an aluminum honeycomb core material and an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com