High-temperature-stability microwave dielectric ceramic for WIFI and preparation method of high-temperature-stability microwave dielectric ceramic

A microwave dielectric ceramic and stable technology, which is applied in the field of microwave dielectric ceramics for high temperature stable WIFI and its preparation, can solve the problems of high process cost, high temperature coefficient of polytitanium-barium system products, high sintering temperature of polytitanium-barium system, etc. problems, to achieve the effect of simple preparation process, non-toxic preparation raw materials, excellent microwave dielectric properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] The present invention further provides a preparation method of the high-temperature stable WIFI microwave dielectric ceramic, comprising the following steps:

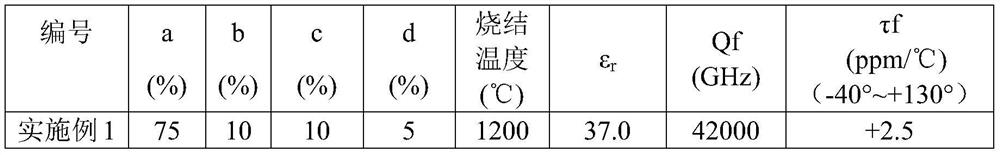

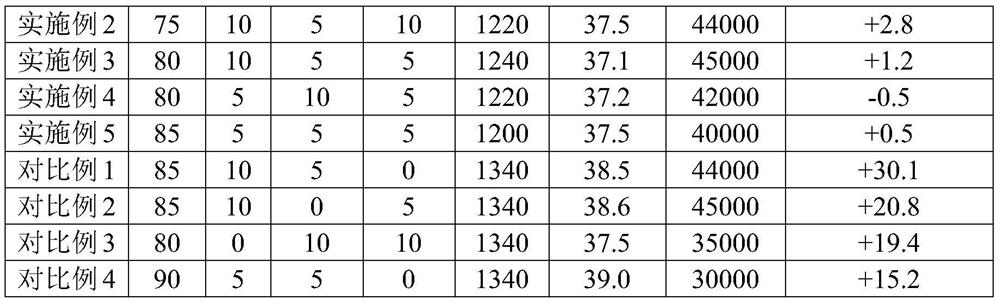

[0029] (1) According to the composition expression aBaTi 4 o 9 -bSnTiO 4 -cLi 2 SiO 3 -dZnSiO 3 Weigh the mole percentage of each element in BaCO 3 、TiO 2 , SiO 2 , Li 2 CO 3 , ZnO, SnO 2 , the weighed material is mixed fully and then ball milled, dried and sieved after ball milling, and then put into a corundum crucible for heat preservation and pre-fired to obtain a powder base material; wherein, in the composition expression aBaTi 4 o 9 -bSnTiO 4 -cLi 2 SiO 3 -dZnSiO 3 Among them, a, b, c, and d independently represent mole percentages, and satisfy the following conditions: 75mol%≤a≤85mol%, 5mol%≤b≤10mol%, 5mol%≤c≤10mol%, 5mol%≤d≤10mol% %, a+b+c+d=100mol%;

[0030] (2) fully ball milling the powder base material obtained in step (1), and then drying, granulating and sieving after ball milling;...

Embodiment 1

[0039] The high temperature stable type WIFI microwave dielectric ceramics of this embodiment 1, its composition expression aBaTi 4 o 9 -bSnTiO 4 -cLi 2 SiO 3 -dZnSiO 3 Among them, a=75mol%, b=10mol%, c=10mol%, d=5mol%.

[0040] The preparation method of the high temperature stable WIFI microwave dielectric ceramic of this embodiment 1 comprises the steps:

[0041] (1) Weigh the BaCO respectively according to the mole percentage of each element in the composition expression 3 、TiO 2 , SiO 2 , Li 2 CO 3 , ZnO, SnO 2 , mixing the weighed materials fully, ball milling, drying and sieving after ball milling, and then putting them into a corundum crucible and pre-burning at 1000°C for 3 hours to obtain a powder base material;

[0042] (2) The powder base material obtained in step (1) is fully ball-milled, then dried, granulated and sieved; wherein the granulated is mixed with the dried powder and polyvinyl alcohol solution, and then prepared into micron-sized spherical ...

Embodiment 2

[0046] The high temperature stable WIFI of this embodiment 2 microwave dielectric ceramics, its composition expression aBaTi 4 o 9 -bSnTiO 4 -cLi 2 SiO 3 -dZnSiO 3 Among them, a=75mol%, b=10mol%, c=5mol%, d=10mol%.

[0047] The preparation method of the high temperature stable WIFI microwave dielectric ceramic of this embodiment 2 comprises the steps:

[0048] (1) Weigh the BaCO respectively according to the mole percentage of each element in the composition expression 3 、TiO 2 , SiO 2 , Li 2 CO 3 , ZnO, SnO 2 , mixing the weighed materials fully, ball milling, drying and sieving after ball milling, and then putting them into a corundum crucible and pre-burning at 1000°C for 3 hours to obtain a powder base material;

[0049] (2) The powder base material obtained in step (1) is fully ball-milled, then dried, granulated and sieved; wherein the granulated is mixed with the dried powder and polyvinyl alcohol solution, and then prepared into micron-sized spherical parti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| relative permittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com