Low-dielectric microwave dielectric ceramic material and temperature-frequency characteristic regulation and control method thereof

A technology of microwave dielectric ceramics and low dielectric, applied in the field of microwave dielectric ceramics, can solve the problems of variable price of Ti-based materials, increase of dielectric constant, decrease of quality factor, etc., achieve stable low dielectric constant, improve quality factor, phase The effect of a single ingredient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] The preparation method of the above-mentioned microwave dielectric ceramic may comprise the following steps:

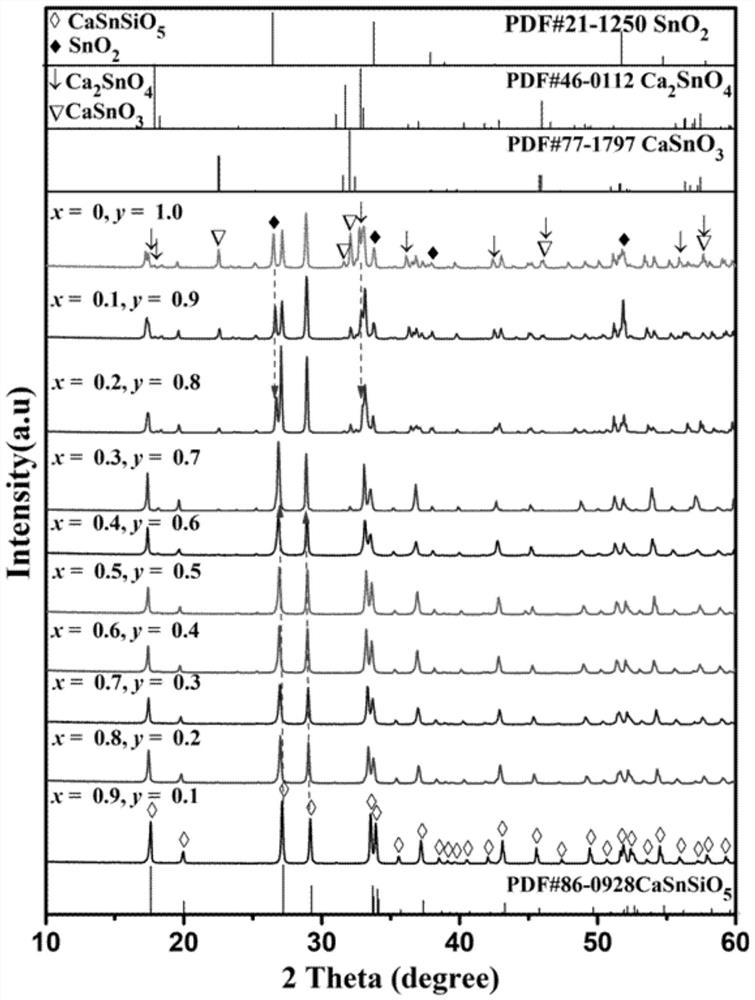

[0030] (1) According to the chemical expression, it is CaO-SnO 2 -xSiO 2 -yGeO 2 The stoichiometric ratio of CaCO 3 , SnO 2 、GeO 2 and SiO 2 , weighed, wet ball milled, dried after ball milled, and then pre-fired to obtain pre-fired ceramic powder;

[0031] (2) The pre-fired ceramic powder obtained in the step (1) is subjected to secondary wet ball milling, after drying, adding a binder to granulate, and then sintering after tableting to obtain the microwave dielectric ceramic.

[0032] Preferably, the pre-burning temperature in step (1) may be 1100-1150° C., and the pre-burning time is 5-10 hours (eg, 10 hours at 1150° C., etc.).

[0033] Preferably, the binder in step (2) is PVA or paraffin, and the mass fraction of the binder can be 5%-10%.

[0034] Preferably, the sintering temperature in step (2) is 1450°C to 1500°C, and the sintering time is 5 hou...

Embodiment 1~11

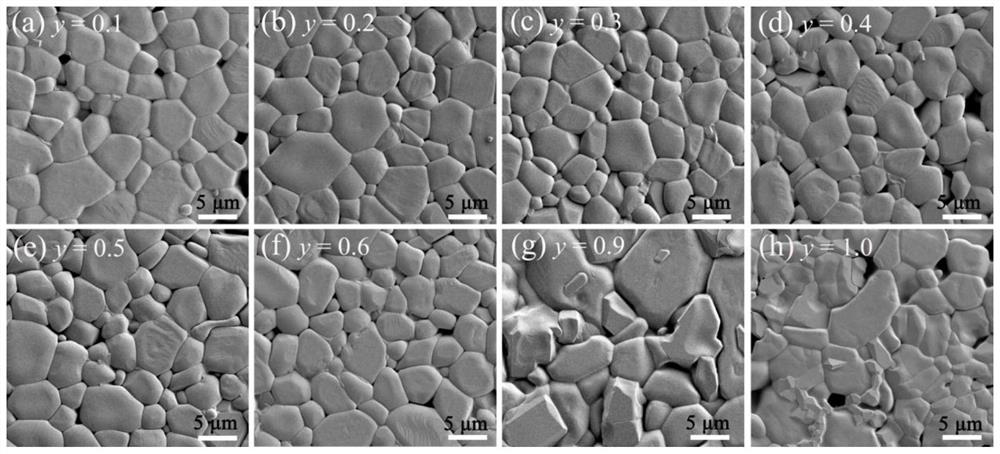

[0038] A microwave dielectric ceramic, its preparation method is carried out according to the following steps:

[0039] (1) Analytical pure CaCO 3 , SiO 2 and SnO with a purity not lower than 99.9% 2 and GeO 2 After mixing according to the stoichiometric ratio, use zirconium balls as the ball milling medium and deionized water as the dispersant, and use a ball mill to mix and stir the powder for 5 hours at a speed of 360r / min; dry the obtained slurry at 1150°C Pre-fired for 5 hours to obtain a pre-fired ceramic powder;

[0040] (2) The pre-fired ceramic powder obtained in step (1) is subjected to wet ball milling again, the dispersant is deionized water, and after drying, 8 wt% polyvinyl alcohol (PVA) binder is added to the dried powder Granulate, and press it into a cylindrical green sample with a thickness to diameter ratio of 0.4 to 0.6 under a pressure of 150 MPa; Dielectric ceramic.

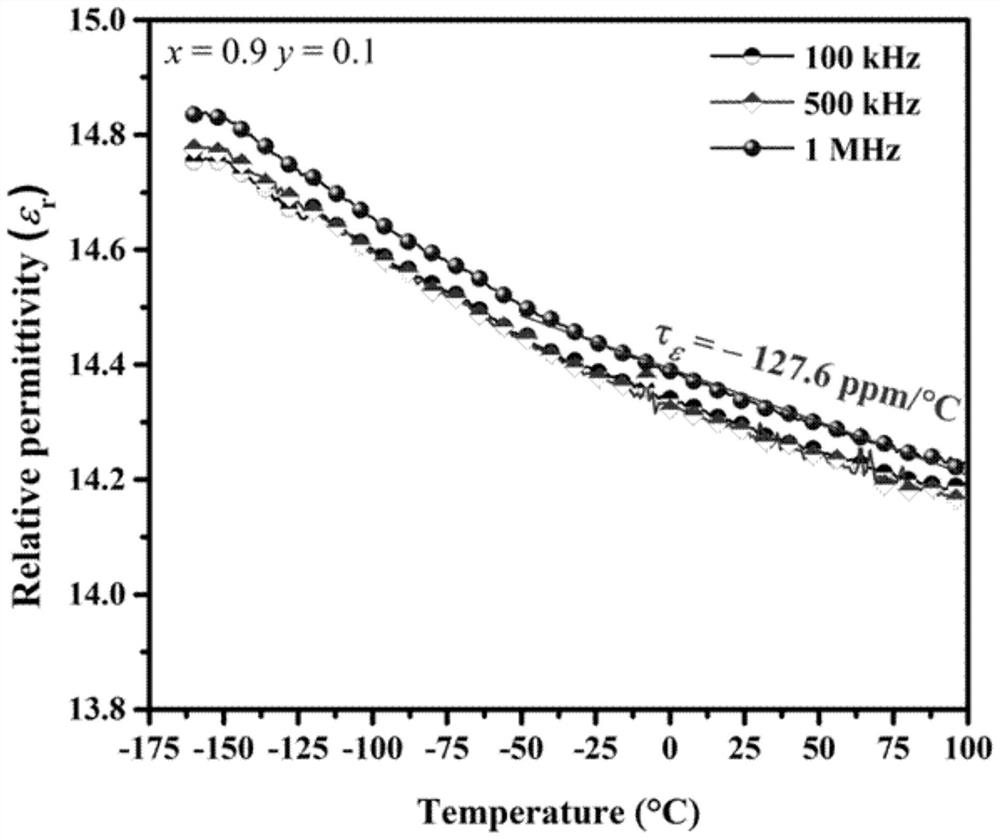

[0041] Table 1 Examples 1-11, sintering temperature and microwave dielectric prope...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Quality factor | aaaaa | aaaaa |

| Resonant frequency temperature coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com