Microwave dielectric ceramic for 5G waveguide with high dielectric constant as well as preparation method and application of microwave dielectric ceramic

A microwave dielectric ceramic, high dielectric constant technology, applied in the direction of waveguides, waveguide devices, circuits, etc., to achieve the effects of excellent microwave dielectric properties, reduced sintering temperature, and high dielectric constant

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

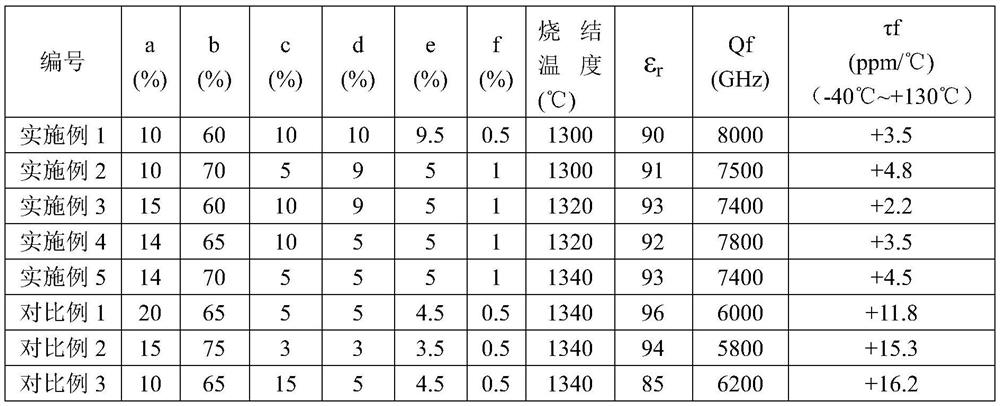

Examples

preparation example Construction

[0026] The present invention further provides a method for preparing the microwave dielectric ceramics for the high dielectric constant 5G waveguide, comprising the following steps:

[0027] (1) According to the molar percentage of BaCO 3 、TiO 2 、Sm 2 o 3 , La 2 O3, Bi 2 o 3 , MnO 2 Carry out batching, ball mill after mixing fully, dry and sieve after ball milling, then put into corundum crucible for heat preservation and pre-firing to obtain powder base material;

[0028] (2) fully ball-milling the powder base material obtained in step (1), drying, granulating, and sieving after ball-milling;

[0029] (3) The sieved mixed powder is pressed into shape, and finally sintered to obtain the microwave dielectric ceramic for 5G waveguide with high dielectric constant.

[0030] The thermal insulation pre-calcination process in the step (1) of the above method is thermal insulation roasting at 1000-1100° C. for 3-5 hours.

[0031] The sintering temperature in step (3) of the ...

Embodiment 1

[0038] The oxide mole percentage composition expression of the high dielectric constant 5G waveguide microwave dielectric ceramic of this embodiment 1 is: 10%BaO-60%TiO 2 -10% Sm 2 o 3 -10% Bi 2 o 3 -9.5% La 2 o 3 -0.5%MnO 2 .

[0039] The preparation method of the microwave dielectric ceramic for the high dielectric constant 5G waveguide of the embodiment 1 comprises the following steps:

[0040] (1) According to the oxide mole percentage in the composition expression to BaCO 3 、TiO 2 、Sm 2 o 3 、La 2 O3, Bi 2 o 3 , MnO 2 Carry out batching, ball mill after mixing sufficiently, dry and sieve after ball milling, then put into corundum crucible and heat-preserve and roast at 1000°C for 3 hours to obtain powder base material;

[0041] (2) The powder base material obtained in step (1) is fully ball-milled, dried, granulated, and sieved after ball-milling; wherein the granulation process is to mix the dried powder with polyvinyl alcohol aqueous solution, and then Ma...

Embodiment 2

[0044] The oxide mole percentage composition expression of the high dielectric constant 5G waveguide microwave dielectric ceramic of this embodiment 2 is: 10%BaO-70%TiO 2 -5% Sm 2 o 3 -9% Bi 2 o 3 -5% La 2 o 3 -1%MnO 2 .

[0045] The preparation method of the microwave dielectric ceramic for the high dielectric constant 5G waveguide of the embodiment 2 comprises the following steps:

[0046] (1) According to the oxide mole percentage in the composition expression to BaCO 3 、TiO 2 、Sm 2 o 3 、La 2 O3, Bi 2 o 3 , MnO 2 Carry out batching, ball mill after mixing sufficiently, dry and sieve after ball milling, then put into corundum crucible and heat-preserve and roast at 1000°C for 3 hours to obtain powder base material;

[0047] (2) The powder base material obtained in step (1) is fully ball-milled, dried, granulated, and sieved after ball-milling; wherein the granulation process is to mix the dried powder with polyvinyl alcohol aqueous solution, and then Made int...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com