Crease-resistant leather shoe material and manufacturing method thereof

A production method and leather technology, applied in leather impregnation, leather surface treatment, small raw hide/big raw hide/leather/fur treatment, etc., can solve the problems of poor softness and comfort of leather, achieve beautiful and high-end products, and prolong service life , enhanced and aesthetically pleasing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

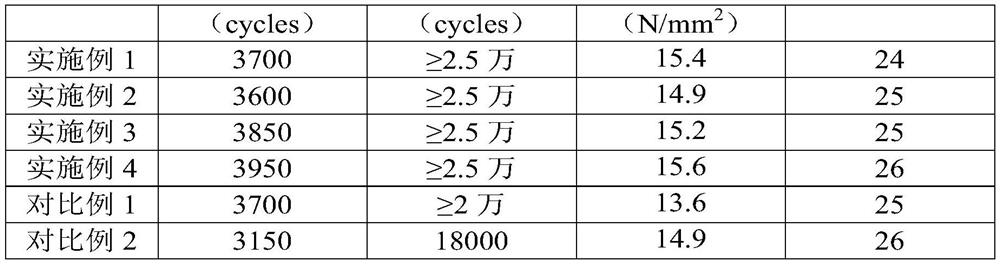

Embodiment 1

[0027] A method for making an anti-wrinkle leather shoe material, comprising the following steps:

[0028] Step S10, put 100 parts of wet blue leather into 100 parts of warm water at 35°C, add 2.2 parts of penetrant, 1.2 parts of sodium acetate, drum for 30 minutes, then add 0.2 parts of baking soda, and drum for 20 minutes;

[0029] Step S20, wash the wet blue leather treated in step S10 with water at room temperature for 10 minutes, put it into the drum after naturally drying, add 100 parts of water, 2 parts of dye, 2.5 parts of chrome tanning agent, drum for 50 minutes, and then add 2 1 part of reclaimed filler and compound fatliquoring agent, drum for 60 minutes, then add 1.0 part of formic acid, drum for 30 minutes, and drain; the preparation method of the above-mentioned recycled filler comprises: crushing leather waste to obtain leather scraps; Add 10 parts of leather scraps to 100 parts of water at 80°C, add 2.2 parts of glacial acetic acid dropwise, keep warm for 3 ho...

Embodiment 2

[0034] A method for making an anti-wrinkle leather shoe material, comprising the following steps:

[0035] Step S10, put 100 parts of wet blue leather into 100 parts of warm water at ~5°C, add ~.5 parts of penetrant, 2.2 parts of sodium acetate, drum for 50 minutes, then add 0.8 parts of baking soda, drum for ~0 minute;

[0036]Step S20, wash the wet blue leather treated in step S10 with water at room temperature for 10 minutes, put it into the drum after drying naturally, add 100 parts of water, ~ parts of dye, 6 parts of chrome tanning agent, drum for 50 minutes, and then add 8.5 1 part of reclaimed filler and compound fatliquoring agent, drum for 90 minutes, then add 2.2 parts of formic acid, drum for 30 minutes, and drain; the preparation method of the above-mentioned recycled filler comprises: breaking leather waste to obtain leather scraps; Add 10 parts of leather scraps to 100 parts of water at 90°C, add 5 parts of glacial acetic acid dropwise, keep warm for 5 hours, a...

Embodiment 3

[0041] A method for making an anti-wrinkle leather shoe material, comprising the following steps:

[0042] Step S10, put 100 parts of wet blue leather into 100 parts of warm water at 38°C, add 2.8 parts of penetrant, 1.5 parts of sodium acetate, drum for ~ 5 minutes, then add 0.6 parts of baking soda, and drum for 25 minutes;

[0043] Step S20, wash the wet blue leather treated in step S10 with water at room temperature for 10 minutes, put it into the drum after naturally drying, add 100 parts of water, 2.5 parts of dye, and 5 parts of chrome tanning agent, drum for 50 minutes, and then add 3 1 part of reclaimed filler and compound fatliquoring agent, drum for 70 minutes, then add 1.2 parts of formic acid, drum for 30 minutes, and drain; the preparation method of the above-mentioned recycled filler comprises: crushing leather waste to obtain leather scraps; Add 10 parts of leather crumbs to 100 parts of water at 82°C, add 1 to 2 parts of glacial acetic acid dropwise, keep warm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com