Multi-physics field decoupling control method and system for air source heat pump drying system

An air source heat pump, decoupling control technology, applied in drying solid materials, heat pump, drying and other directions, can solve the problems of low dehumidification efficiency, low energy efficiency, rough control, etc., and achieve the effect of improving dehumidification efficiency and improving dehumidification efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

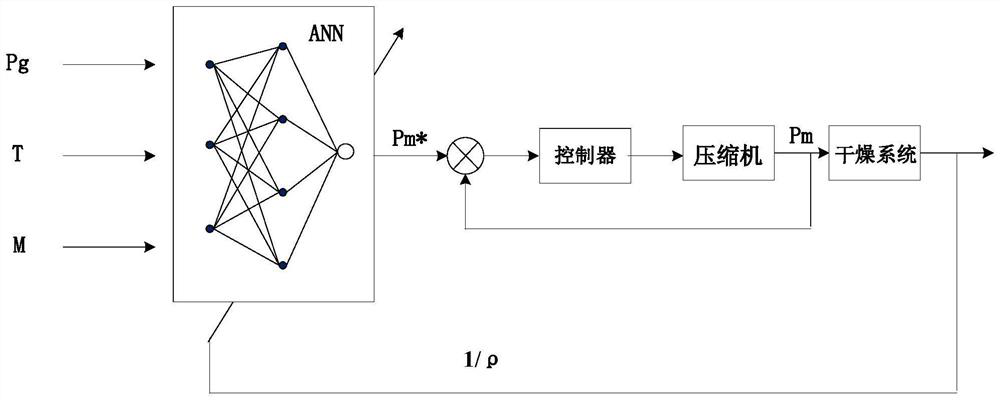

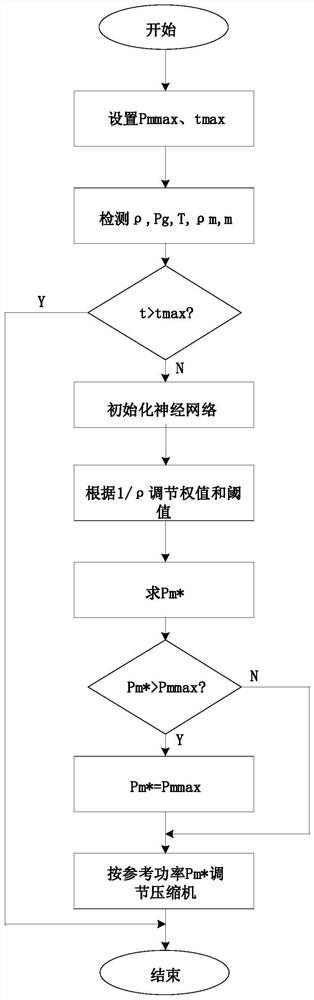

[0064] A specific embodiment of the present invention provides a multi-physics field decoupling control method for an air source heat pump drying system, as shown in Figure 1, including the following steps:

[0065] S1: Collect the air pressure, temperature and humidity in the oven, as well as the dehumidification efficiency in the oven;

[0066] S2: Detect the power supply of the compressor, and perform decoupling control through the trained neural network to obtain the reference power of the compressor, and control the compressor according to the reference power.

[0067] The dehumidification efficiency ρ in the oven is calculated as follows:

[0068]

[0069] ΔW=W t -W t-1 ;

[0070] ΔE=E t -E t-1 ;

[0071] In the formula, ΔW is the weight of the material lost in drying, and ΔE is the electric energy consumed by drying the material with a weight of ΔW; the dehumidification efficiency of the heat pump drying system is obtained by the difference in material weight a...

Embodiment 2

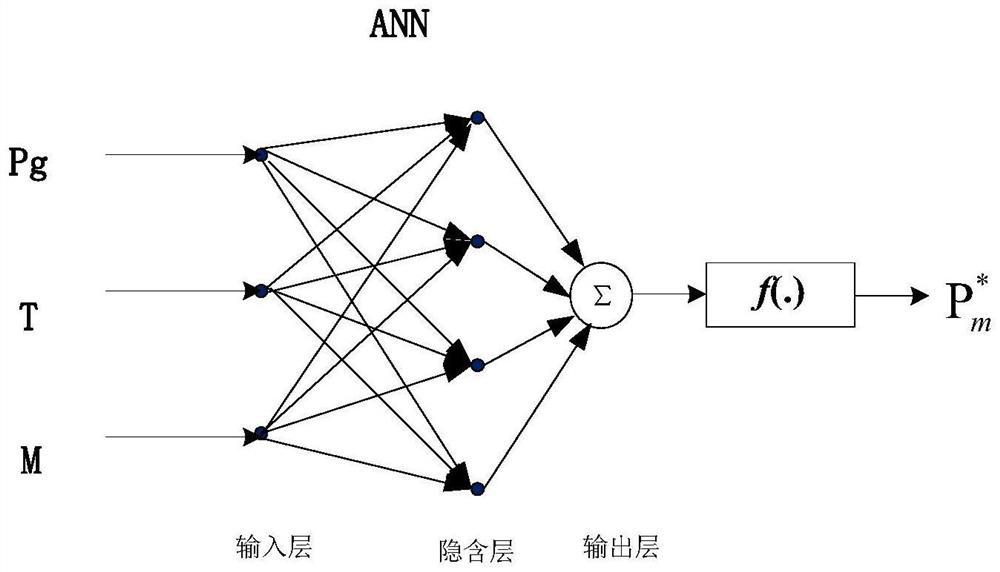

[0114] Such as Figure 5 As shown, in this embodiment, an adaptive neural network is used for decoupling automatic control. In this example, the nonlinear auto-regressive neural network NARX (Nonlinear Auto-regressive with External Inputs) with external input is used. Its output is not only related to the current input, but also related to the past output. In terms of topological connection, it can be equal to The effect is a BP neural network with input delay plus a delay feedback from output to input, which belongs to a dynamic recursive neural network with feedback. Because the NARX neural network contains multi-step input and output delays, it can reflect the historical state information of the system, so the network has a memory function, which can better describe the characteristics of the time-varying system. The model of the NARX neural network can be defined as:

[0115] y(t)=f[y(t-1),y(t-2),...,y(t-n y ),

[0116] u(t-1),u(t-2),···,u(t-n u )];

[0117] In the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com