Formation method of semiconductor structure and semiconductor structure

A semiconductor and contact structure technology, which is applied in semiconductor/solid-state device manufacturing, transistors, electrical components, etc., and can solve problems such as short-circuiting of wires in capacitive contact pads and partial structural damage of virtual capacitive contact structures.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

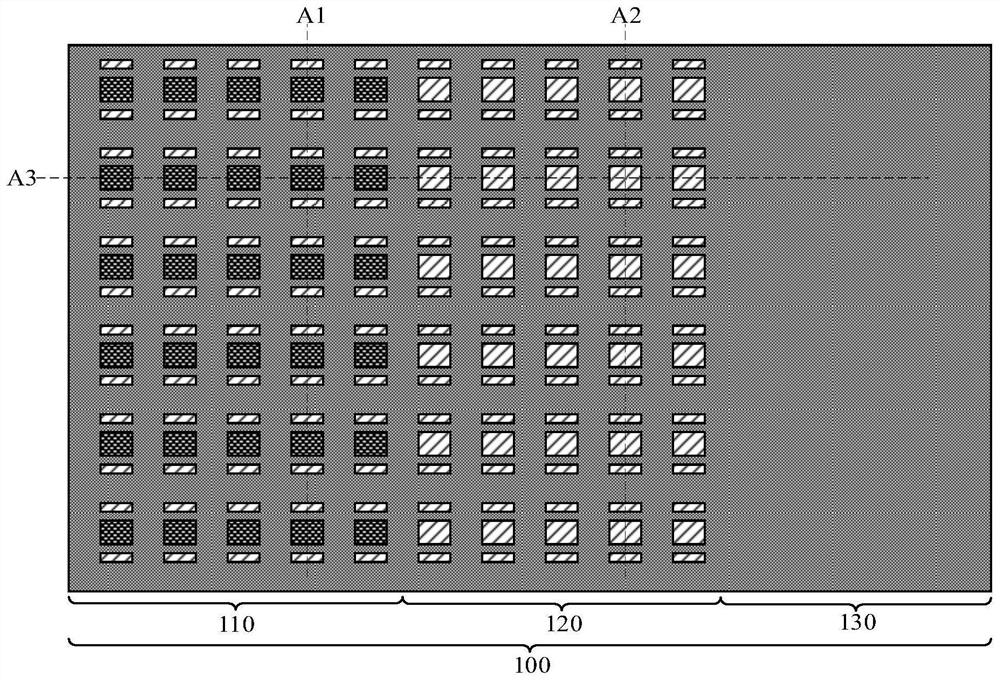

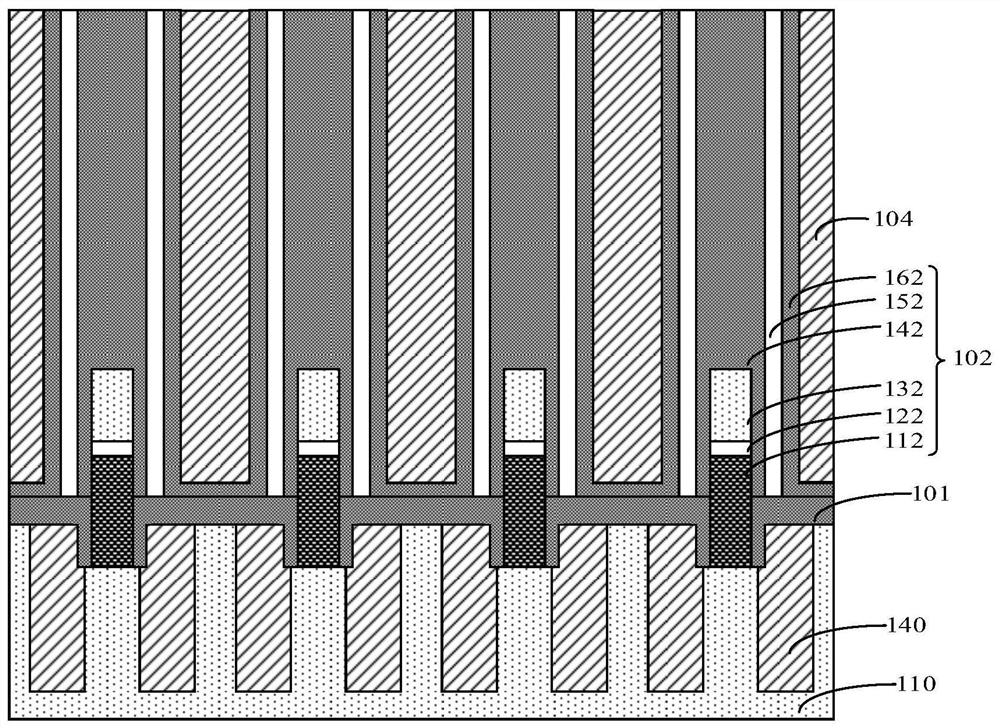

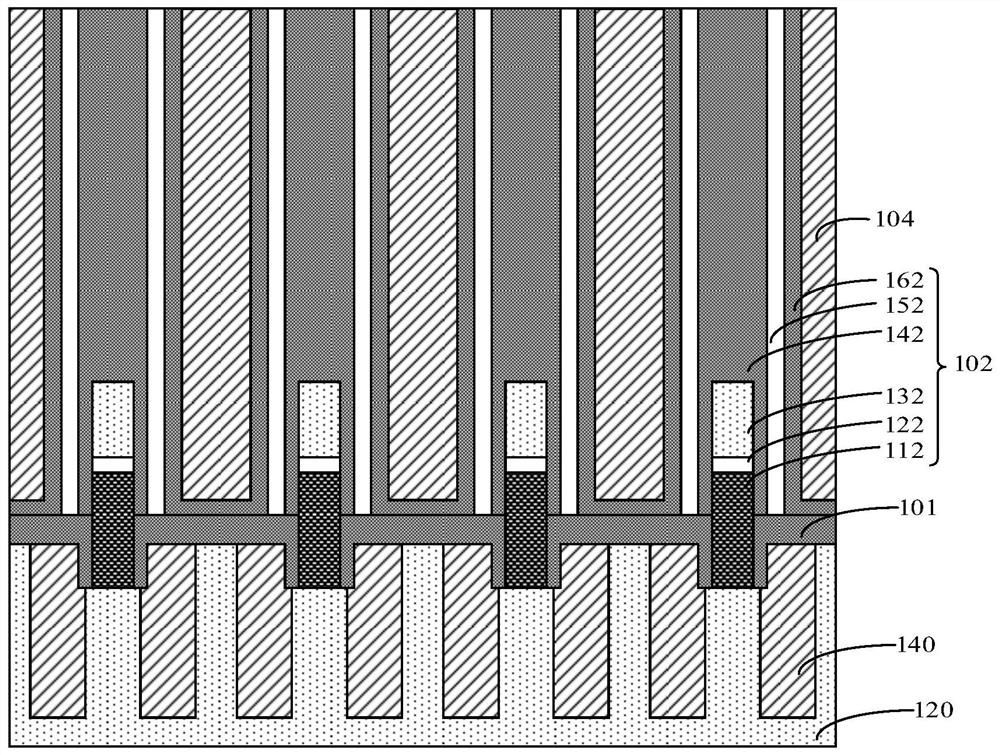

[0026] At present, due to the requirements of the manufacturing process, multiple wet cleaning processes are required in the process flow of the capacitive contact structure. The wet cleaning process has an etching load effect, and the etching rate of the etch-intensive area will be correspondingly reduced. , resulting in over-etching of other structures during the process of forming the capacitive contact opening, for example, over-etching of the dummy capacitive contact structure, resulting in deep voids in the dummy capacitive contact structure. Later, when forming the wires of the capacitor contact pads, some metal materials are filled into the cavities. With the shrinking of the key dimensions, the wires of the capacitor contact pads are arranged more and more densely, and the conductive part of the metal materials of the adjacent capacitor contact pads may be filled. into the same void, resulting in short circuiting of the wires of the formed capacitive contact pad.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com