Method for improving recovery efficiency by regulating and controlling microbial flooding oil reservoir

A microbial oil flooding and recovery technology, applied in chemical instruments and methods, production fluids, earth drilling and production, etc., can solve problems such as poor pertinence and effectiveness, poor field test results, neglect of detection, etc., and achieve low control costs , clear control ideas, pertinence and operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0072] General situation of test block G of an oil production plant in Shengli Oilfield: the reservoir temperature is 65°C, and the permeability is 620×10 -3 μm 2 , formation water salinity 10500mg / L, porosity 28%, crude oil viscosity 1200mPa·s, comprehensive water cut 93.0%. After laboratory test evaluation, this block is suitable for endogenous microbial flooding. The optimized activator formula is glucose concentration 5wt%, beef extract concentration 0.3wt%, dipotassium hydrogen phosphate concentration 0.05wt%. 2 injection wells, 6 oil wells, geological reserves 6.62×10 5 tons, the pore volume is 2.0×10 6 m 3 .

[0073] Utilize the method of the present invention to monitor the produced liquid in the microbial flooding process and make adjustments in time to further improve the oil recovery. The specific steps are as follows:

[0074] (1) Determination of testing indicators and plans for test reservoirs

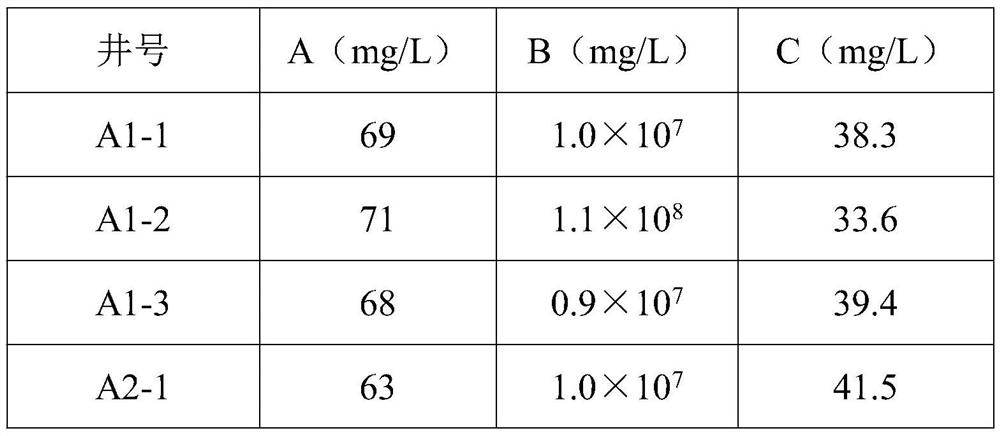

[0075] The detection indicators of the test block G are the c...

Embodiment 2

[0097] General situation of test block H of an oil production plant in Shengli Oilfield: Reservoir temperature is 86°C, permeability is 310×10 -3 μm 2 , formation water salinity 7800mg / L, porosity 23.6%, crude oil viscosity 800mPa·s, comprehensive water cut 68.0%. After laboratory test evaluation, this block is suitable for endogenous microbial flooding. The optimized activator formula is 4.5% glycerin, 0.25% peptone (nitrogen source) and 0.05% diammonium hydrogen phosphate. 3 injection wells, 12 oil wells, geological reserves 1.32×10 6 tons, pore volume 7.2×10 6 m 3 .

[0098] Utilize the method of the present invention to monitor the produced liquid in the microbial flooding process and make adjustments in time to further improve the oil recovery. The specific steps are as follows:

[0099] (1) Determination of testing indicators and plans for test reservoirs

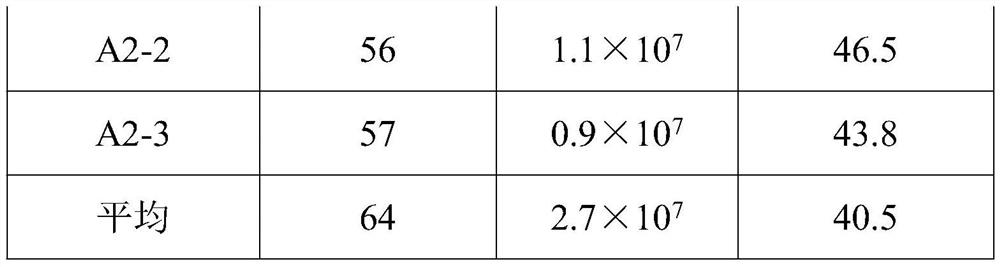

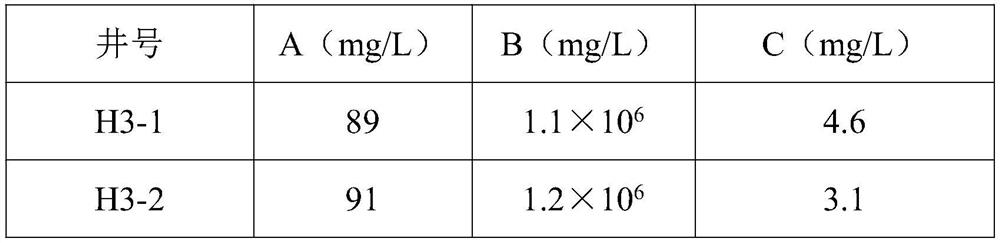

[0100] The detection indicators of test block H include acetic acid concentration A, methanogen concentratio...

Embodiment 3

[0124] General situation of test block K of an oil production plant in Shengli Oilfield: the reservoir temperature is 93°C, and the permeability is 360×10 -3 μm 2 , formation water salinity 10500mg / L, porosity 26.0%, crude oil viscosity 1200mPa·s, comprehensive water cut 97.0%. After laboratory test evaluation, this block is suitable for endogenous microbial flooding. The optimized activator formula is 5% of corn dextrin (carbon source), 0.3% of sodium nitrate (nitrogen source), and 0.1% of dipotassium hydrogen phosphate. 2 injection wells, 8 oil wells, geological reserves 9.0×10 6 tons, pore volume 5.0×10 7 m 3 .

[0125] Utilize the method of the present invention to monitor the produced fluid in the process of microbial oil displacement and make adjustments in time to further improve the oil recovery rate of the oil reservoir. The specific steps are as follows:

[0126] (1) Determination of testing indicators and plans for test reservoirs

[0127] The detection indic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com