Feeding structure, uniform material distribution system and material distribution method

A technology of uniform material distribution and feeding, which is applied in the direction of solid separation and sorting, which can solve the problems of poor material tiling and arrangement, and achieve the effect of improving sorting accuracy and avoiding harmful effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

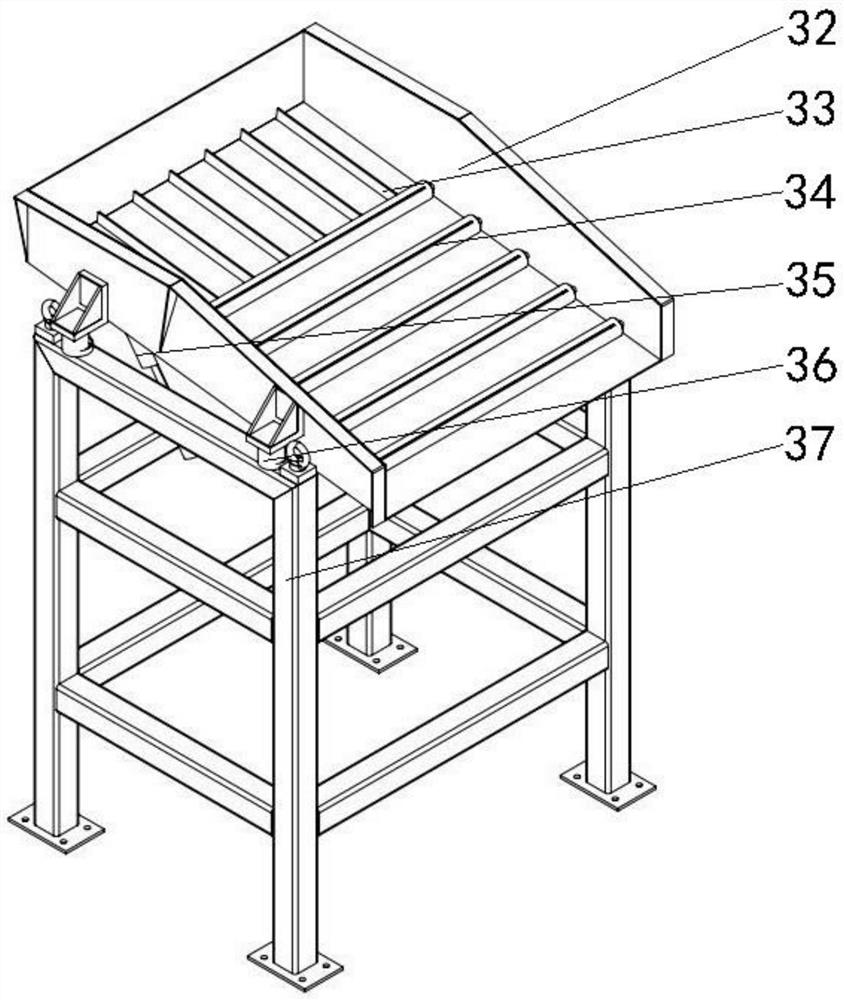

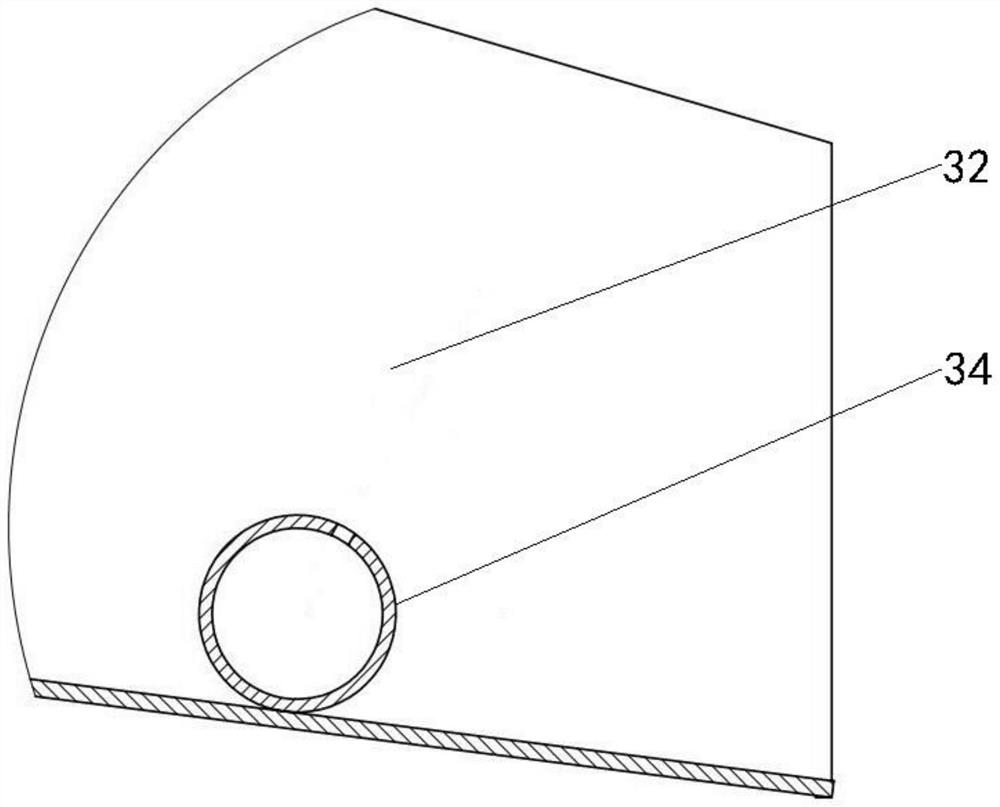

[0050] This embodiment provides a kind of feeding structure, with reference to figure 2 , the feeding structure 3 includes a lower hopper 32, a plurality of grid plates 33 and a plurality of high-pressure air injection pipes 34, the lower hopper 32 has a feed end and a discharge end, and the lower hopper 32 includes a first lower material part and a second lower material part. Material section; the first blanking section is located on the feed end side of the lower hopper 32, and the second blanking section is located on the discharge end side of the lower hopper 32; a plurality of grid plates 33 are located on the first blanking section, A plurality of high-pressure jet pipes 34 are located at the second blanking part, and the grid plate 33 is used to guide the material to the second blanking part; the high-pressure jet pipe 34 is provided with a spout in a direction parallel to its own axial direction, and the high-pressure jet pipe 34 It is used to communicate with an exte...

Embodiment 2

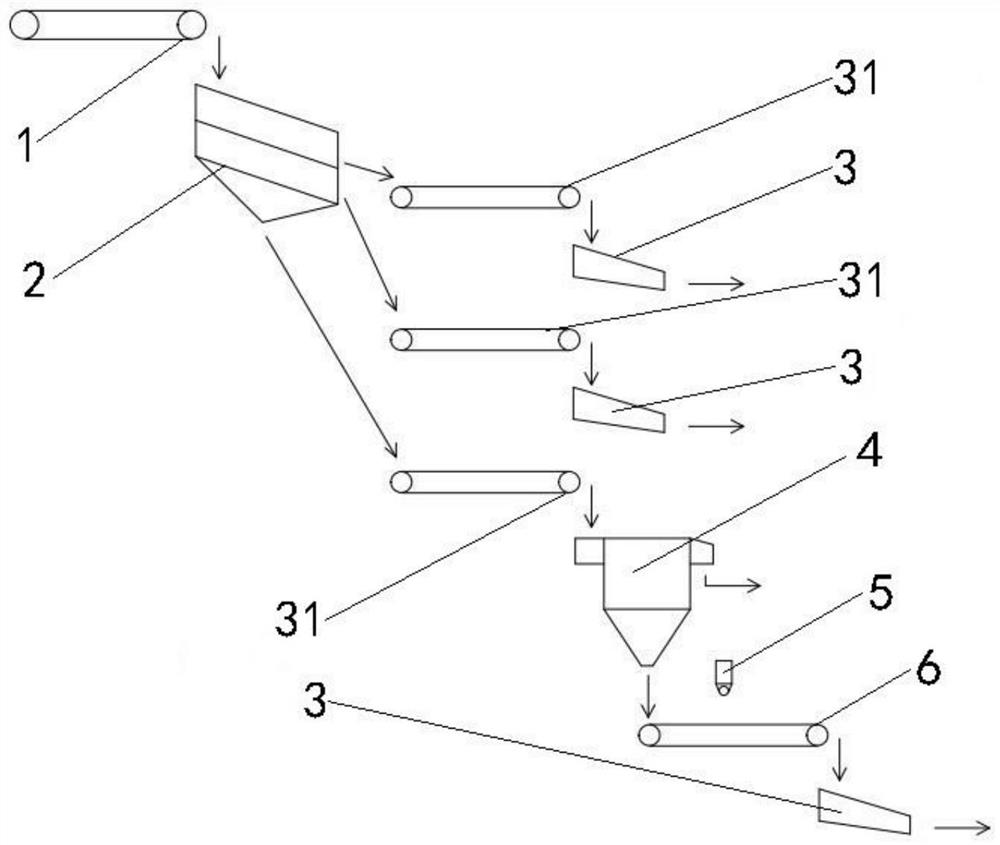

[0061] This embodiment provides a uniform distribution system, refer to figure 1 , including feeding belt 1, double-layer vibrating screen 2, material receiving mechanism and multiple feeding structures 3, feeding belt 1, double-layer vibrating screen 2, material receiving mechanism and feeding structure 3 are arranged in sequence; the discharge of feeding belt 1 The end is connected with the feed end of the double-layer vibrating screen 2; the double-layer vibrating screen 2 is provided with a multi-stage discharge end, and the discharge ends of each level of the double-layer vibrating screen 2 pass through the material receiving mechanism and the corresponding feeding structure 3 respectively. The feed end is connected.

[0062] Specifically: the discharge ends of each level of the double-layer vibrating screen 2 are respectively connected to the feed end of the corresponding feeding structure 3 through the material receiving mechanism, and the double-layer vibrating screen ...

Embodiment 3

[0069] This embodiment provides a method for distributing materials, including: double-layer vibrating sieve 2 screens the materials conveyed by the feeding belt 1, and after the materials are separated by particle size through the double-layer vibrating sieve 2, materials of different particle sizes are discharged from multiple stages. The material is discharged from the material end and sent to the corresponding feeding structure 3 through the conveyor belt 31; the larger-grained material is vibrated by the corresponding feeding structure 3 and then flattened at the outlet of the lower hopper 32 and discharged into the external intelligent sorting machine for sorting Processing; materials with smaller particle size are conveyed to the jig machine 4 through the conveyor belt 31. After the jigging treatment, the selected materials are conveyed to the corresponding feeding structure 3 through the conveyor belt 6 and dried by the blower 5. After the material structure 3 vibrates,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com