Anti-puncture material and anti-puncture fabric structure

A puncture-proof and stab-proof technology, applied in protective clothing, clothing, layered products, etc., can solve the problems of heavy weight of stab-proof sheets, easy consumption of physical strength of wearers, etc. Piercing performance, weight saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] This embodiment discloses a puncture-resistant material.

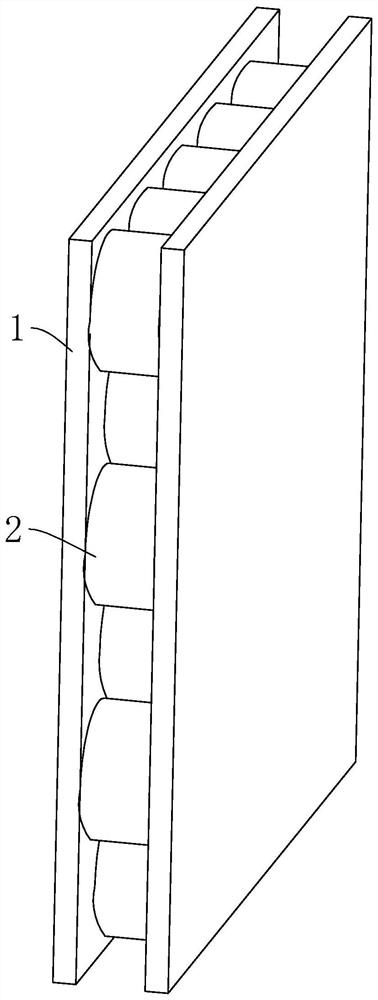

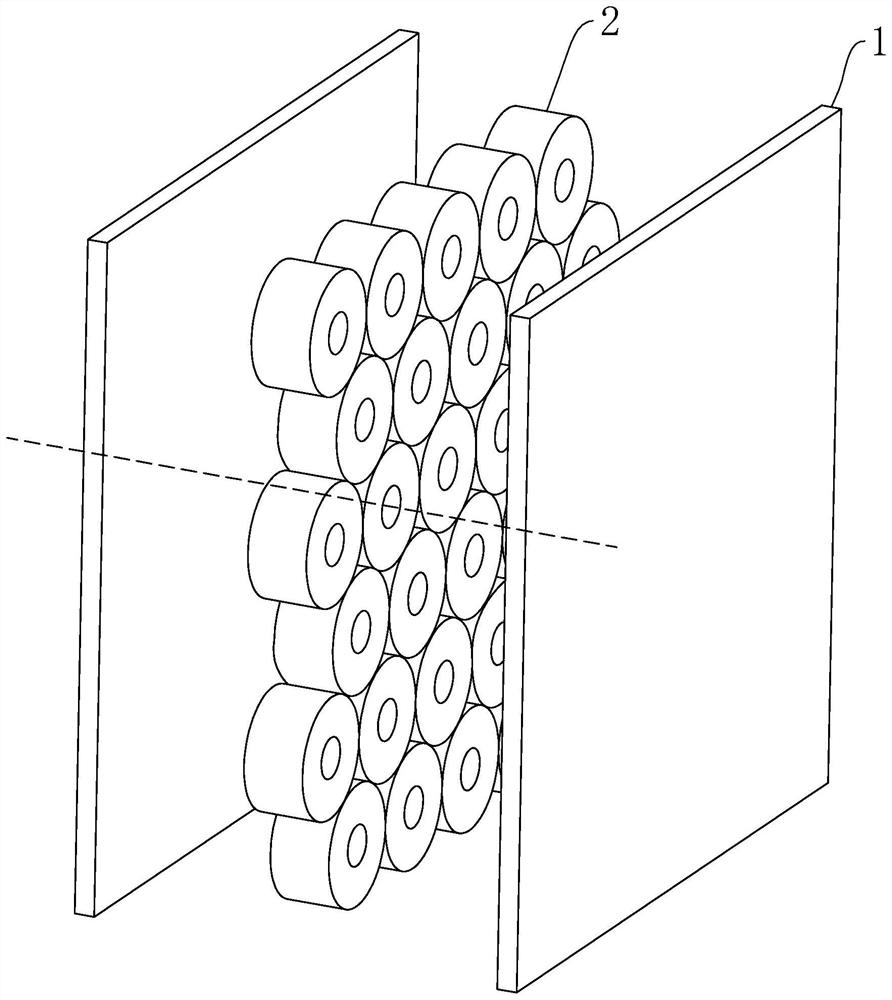

[0045] refer to figure 1 The anti-puncture material includes a surface plate 1 and several hollow fiber tubes 2, the axial directions of the several hollow fiber tubes 2 are the same, and the adjacent hollow fiber tubes 2 are bonded to each other. There are at least two surface plates 1 , and there are two surface plates 1 in this embodiment, one surface plate 1 is bonded to one end of the hollow fiber tube 2 , and the other surface plate 1 is bonded to the other end of the hollow fiber tube 2 .

[0046] The hollow fiber tube 2 is a composite tube made of a filament fiber braided tube and a polymer material. The filament fiber braided tube is a tube braided by any one of carbon fiber filaments, glass fiber filaments or basalt fiber filaments. The polymer material is any one of nylon, polycarbonate and polypropylene. The hollow fiber tube 2 in this embodiment is a composite tube made of carbon fiber filament bra...

Embodiment 2

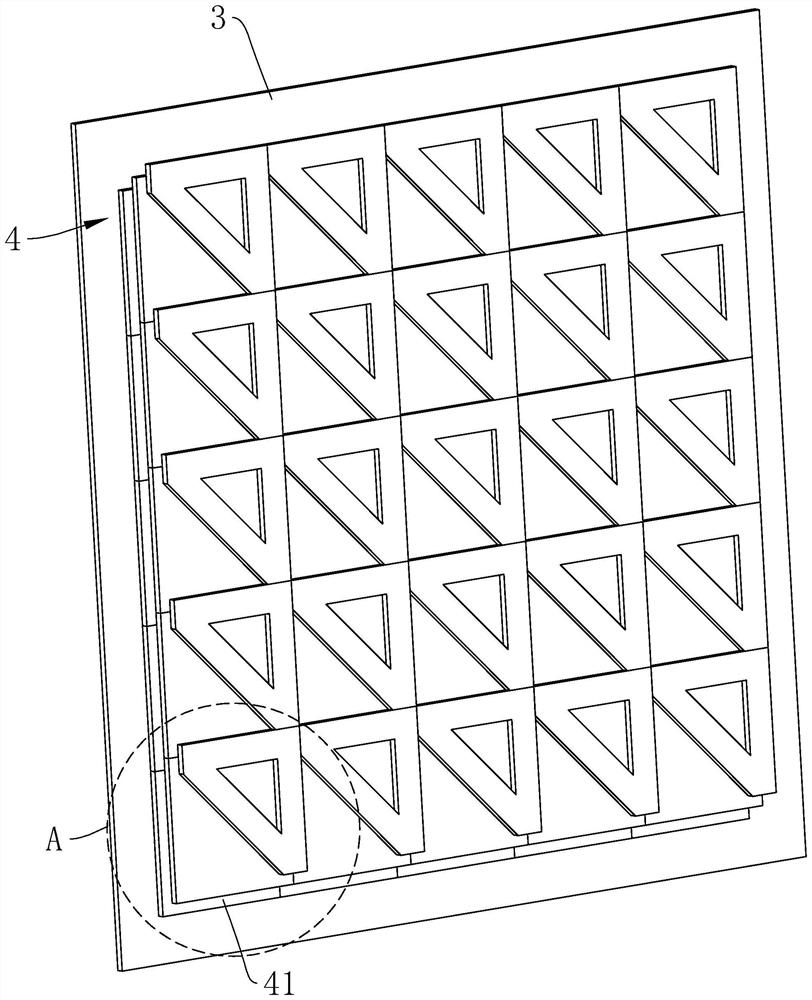

[0061] refer to Image 6 , The difference between this embodiment and Embodiment 1 is that the base cloth 3 includes a front cloth 31 and a rear cloth 32 . There are multiple front cloths 31 and back cloths 32, all front cloths 31 are laid in sequence along the same direction, and two adjacent front cloths 31 are sewn together. All the back cloths 32 are laid in the same direction, two adjacent back cloths 32 are sewn together, and the front cloth 31 is positioned above the back cloth 32 .

[0062] Both the upper surfaces of the front cloth 31 and the back cloth 32 are bonded with the anti-stab layer 4 . Each anti-stab layer 4 includes two anti-stab strips parallel to each other. When the front cloth 31 and the back cloth 32 are tiled, the anti-stab layer 4 on the back cloth 32 is located below the junction of two adjacent front cloths 31, and the back cloth 32 and the front cloth 31 are sewn together.

[0063] The front cloth 31 and the back cloth 32 are bent, the anti-sta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com