Solution-processable exciplex host material, preparation method and application

A technology of exciplexes and host materials, which is applied in the fields of luminescent materials, chemical instruments and methods, semiconductor/solid-state device manufacturing, etc., can solve the problems of many side reaction products, slow research progress, long synthesis route, etc., and achieve enhanced dissolution and film-forming effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

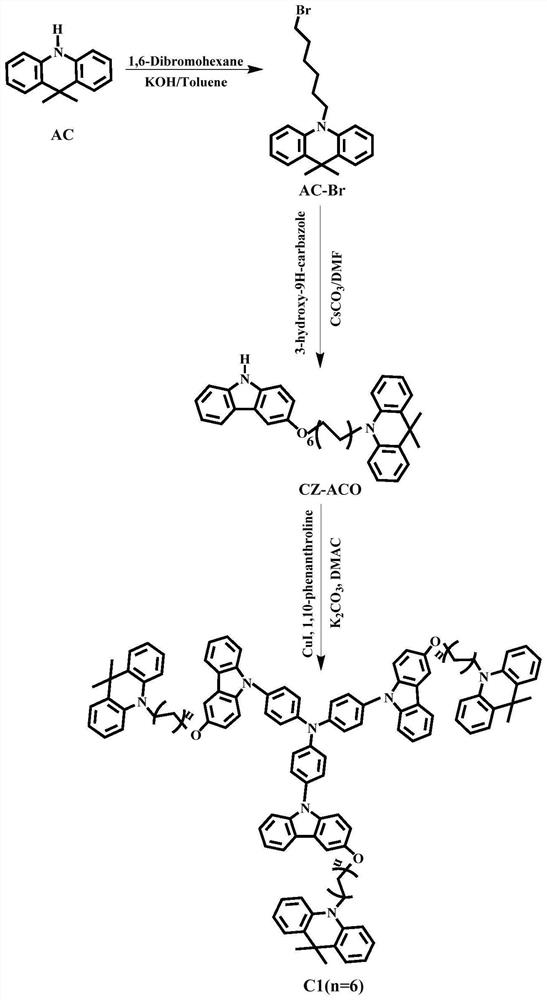

[0041] Embodiment 1: as figure 1 As shown, compound C1 was synthesized by the following method

[0042]Step 1: Synthesis of AC-Br: Add 9,10-dihydro-9,9-dimethylacridine (4.0 g, 23.92 mmol), 1,6-dibromohexane to toluene solution (80 mL) (33mL, 143.5mmol), KOH (15g, 267.85mmol, first dissolved in 10mL of water), tetrabutylammonium bromide (1g, 1.8mmol). Under the protection of nitrogen, the reaction was stirred at 80° C. for 3 h, and directly spin-dried after the reaction. Purified by column chromatography to obtain the AC-Br product with a yield of 71%.

[0043] Step 2: Synthesis of CZ-ACO: under nitrogen protection, add AC-Br (2.67g, 8.13mmol), 3-hydroxycarbazole (1.59g, 8.13mmol), cesium carbonate (6.7g, 21.12 mmol), DMF (30mL), react at 80°C for 3h. Cool after the reaction, add water to precipitate, and extract with dichloromethane to obtain the product CZ-ACO with a yield of 68%.

[0044] Step 3: Synthesis of C1: Add CZ-ACO (1.42g, 3.15mmol), 4,4',4″-triiodotriphenylam...

Embodiment 2

[0045] Embodiment 2: the synthesis of compound C2

[0046] In the above example, the 3-hydroxycarbazole reacted with AC-Br was replaced with 3,6-dihydroxy-9-hydrogen-carbazole, and the product C2 was obtained through the same synthesis method as in Example 1. Yield 61%. Mass spectrum: 2720.85. Elemental analysis, the results are as follows: C: 83.47, H: 7.76, N: 5.12.

Embodiment 3

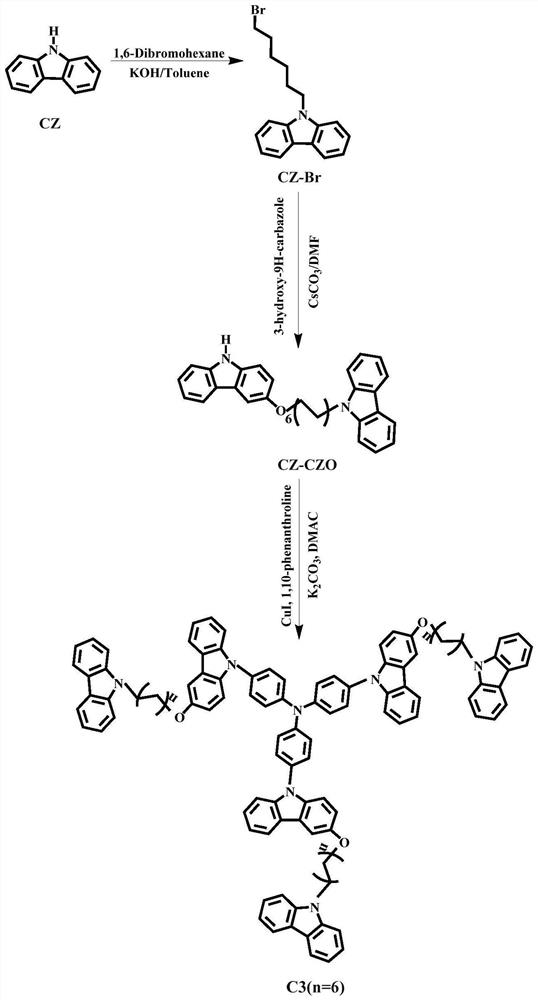

[0047] Embodiment 3: as figure 2 As shown, compound C3 was synthesized by the following method

[0048] Step 1: Synthesis of branched CZ-Br: Add carbazole (6.7 g, 23.92 mmol), 1,6-dibromohexane (33 mL, 143.5 mmol), KOH (15 g, 267.85 mmol, first dissolved in 10mL water), tetrabutylammonium bromide (1g, 1.8mmol). Under the protection of nitrogen, the reaction was stirred at 80° C. for 3 h, and directly spin-dried after the reaction. Purified by column chromatography to obtain the CZ-Br product with a yield of 71%.

[0049] Step 2: Synthesis of CZ-CZO: Under nitrogen protection environment, add CZ-Br (3.62g, 8.13mmol), 3-hydroxycarbazole (1.59g, 8.13mmol), cesium carbonate (6.7g, 21.12 mmol), DMF (30 mL). The reaction conditions and post-reaction treatment are the same as the synthesis of CZ-ACO in Example 1. The product CZ-CZO was obtained with a yield of 60%.

[0050] Step 3: Synthesis of C3: Add CZ-CZO (2.63g, 6.08mmol), 4,4',4″-triiodotriphenylamine (3I-TPA) (1.18g, 1....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com