High-temperature-resistant oil-based foam drilling fluid and preparation method thereof

A technology for high temperature resistance and drilling fluid, which is applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve the problems of short half-life of oil-based foam drilling fluid, etc., and achieve strong rock-carrying ability, prevent lost circulation and stable performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

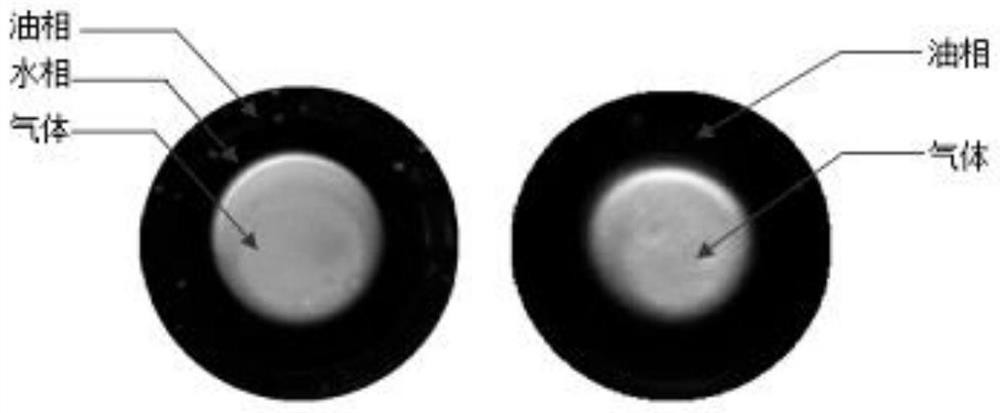

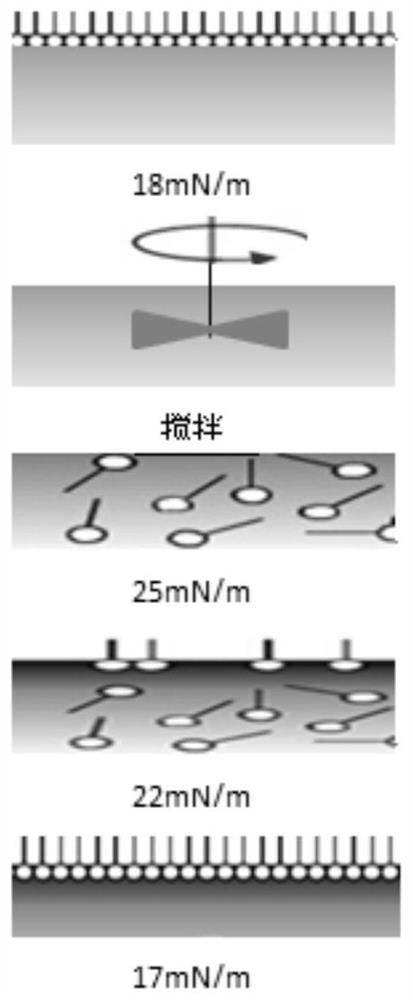

[0045] An embodiment of the present invention provides a method for preparing the above-mentioned high temperature resistant oil-based foam drilling fluid, comprising: mixing a foaming agent, a foam stabilizer, an emulsifier, water and a base oil according to the proportion, Stir to form foam to obtain high temperature resistant oil-based foam drilling fluid.

[0046] Specifically, the preparation method of the oil-based foam drilling fluid is:

[0047] Add 100-120mL of base oil into the high stirring cup, then add a small amount of foaming agent, foam stabilizer, emulsifier and a small amount of water in turn, and stir for 5-10 minutes at high speed for each treatment agent added, at a speed of 10000-12000r / min After adding all the ingredients, keep stirring until the volume of the foam no longer increases, that is to say.

[0048] In the embodiment of the present invention, the above-mentioned high stirring cup can be removed, the foam drilling fluid is poured into a 1000mL...

Embodiment 1

[0058] Take 120mL of diesel oil, add the amount of treating agent according to the volume percentage of base oil, add 1% YF-10, 1% YF111, 1% span80, 1% silicone 2235 surfactant in sequence, and stir at 12000r / min until The foam volume does not increase any more.

[0059] The specific operation steps are as follows:

[0060] (1) Use a graduated cylinder to measure 120mL of diesel oil and add it to a high stirring cup, add 1% YF-10 to the high stirring cup, then place it in a water bath at 60°C and heat it, stirring constantly to completely disperse the solid in the diesel oil, stirring at high speed for 5 minutes , no large amount of foam was found.

[0061] (2) Continue to add 1% YF111 to (1), stir at high speed for 5 minutes, the foam will increase, but the foam will not be fine and fine, and the foam will disappear quickly.

[0062] (3) Add 1% span80 to (2), stir at high speed for 5 minutes, the foam is delicate and the foam quality is improved.

[0063] (4) Continue to a...

Embodiment 2

[0069] Take 120mL of diesel oil and pour it into a high stirring cup, then add 1% silicone 4018 surfactant, 1% YF-10, 1% span80, 1% YF-111 in sequence, the preparation process is as in Example 1. The volume of the foam no longer increases, pour it into a graduated cylinder to measure the volume, and press the stopwatch to record the time to obtain its half-life.

[0070] The result of foaming is: the volume of foam is 736mL, the half-life is 15min, and the quality of foam is 83.7%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com