Temperature-resistant and salt-resistant flow regulating agent suitable for fractured-vuggy oil reservoir as well as preparation method and application of temperature-resistant and salt-resistant flow regulating agent

A temperature-resistant, salt-resistant, fracture-cavity technology, used in chemical instruments and methods, production fluids, earth-moving drilling, etc. Yield, intensity controllable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0060] The composition of the temperature-resistant and salt-resistant "four controllable" flow regulator systems suitable for fracture-vug reservoirs of the present embodiment is: 55 parts (weight) of thermoplastic resins, 18 parts of strength regulators, 24 parts of inorganic salts, white oil 3 copies.

[0061] The temperature-resistant and salt-resistant performance of the flow regulating agent of the present invention means that it can be within 150°C, and the salinity is 22×10 4 mg / l environment, placing it in a constant temperature box for half a year will not affect its performance and selective sealing effect.

[0062] First, stir all the medicines in the mixing equipment at a temperature of 30 degrees for 10 minutes, and set the temperature of the extruder to: 170°C, 220°C, 220°C, 220°C, 220°C, 210°C, 200°C, 190°C ℃, 190℃, 180℃, 180℃, 170℃ for preheating. Then start the main engine, the rotating speed is adjusted to 355rpm, the feeding speed is 33rpm, the traction s...

Embodiment 2-4

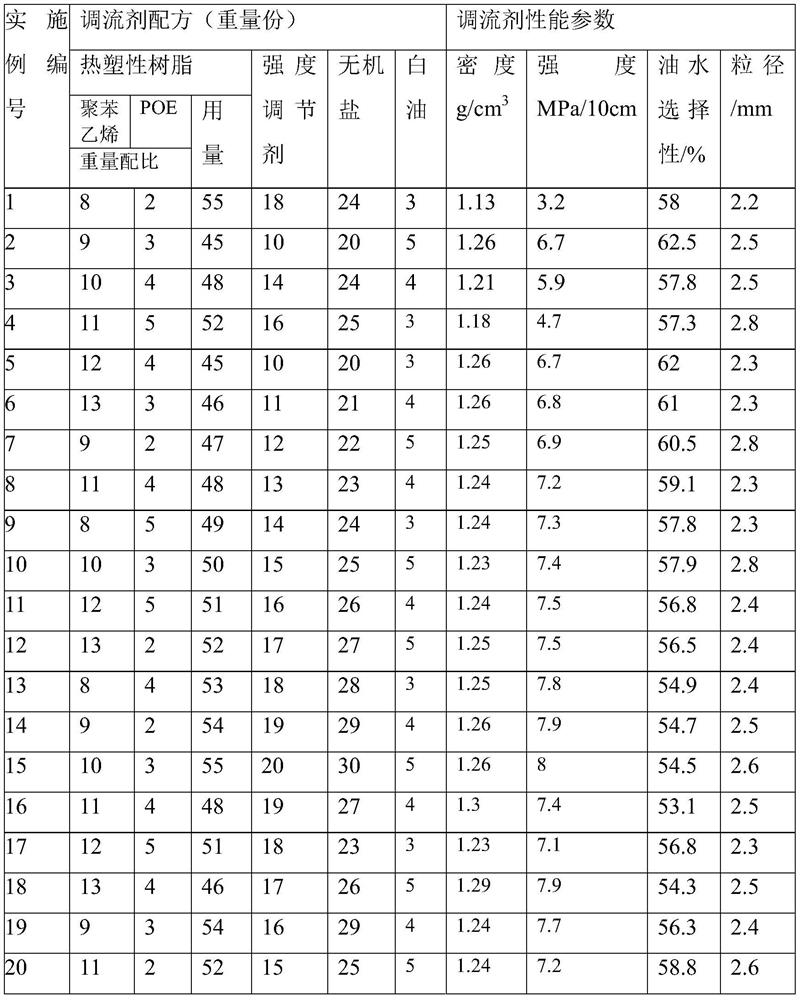

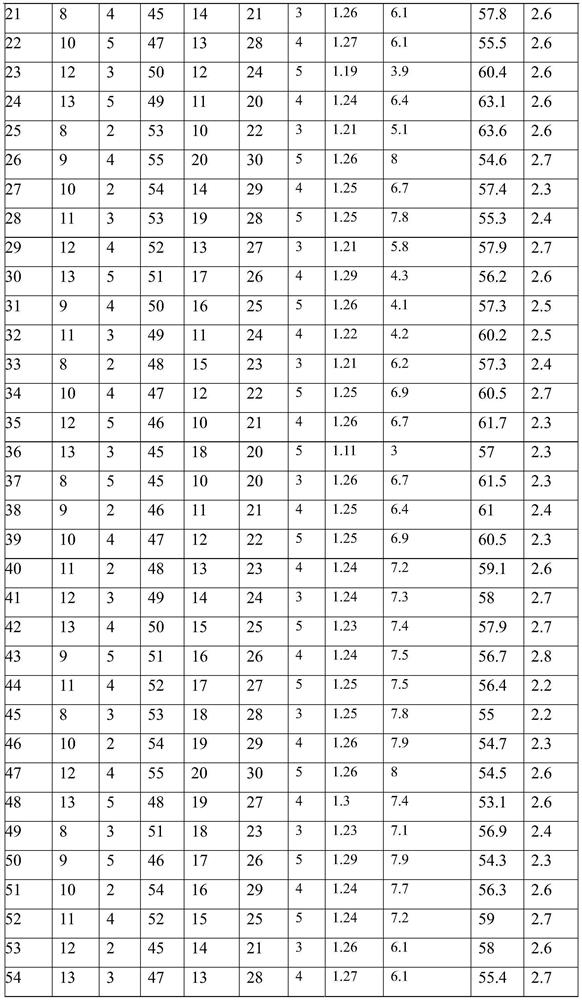

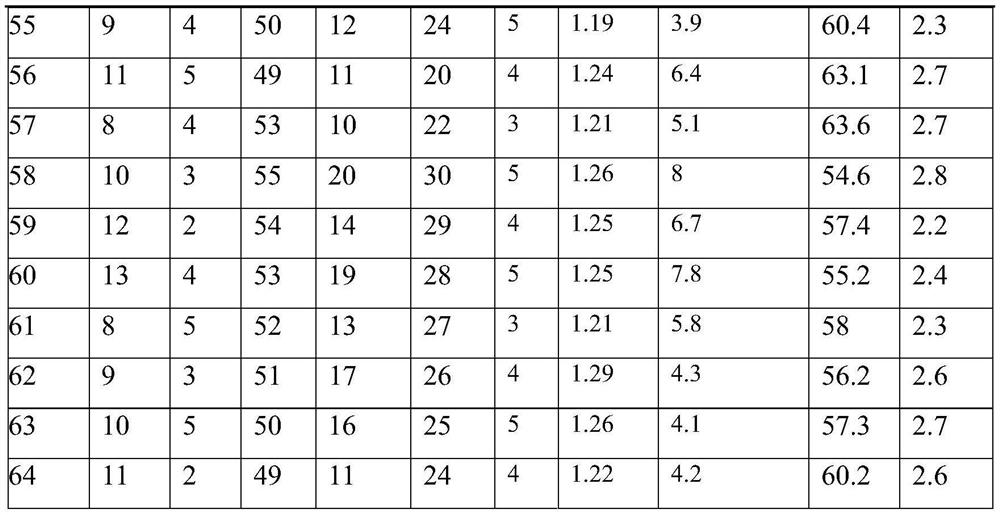

[0064] The compositions of the "four controllable" flow regulator particles of Examples 2-4 are shown in Table 1. The preparation method of the "four controllable" flow regulator particles in Examples 2 and 4 is the same as that in Example 1.

[0065] The product of the present invention is simulated formation temperature 130 ℃, salinity 20 * 10 4 mg / L reservoir conditions, the main performance parameters of the "four controllable" flow regulator particles of each embodiment are shown in Table 2.

[0066] The content of each component of "four controllable" flow regulator particles in the embodiment 2-4 of table 1 (unit: parts by weight)

[0067] components Example 2 Example 3 Example 4 thermoplastic resin 45 48 52 strength modifier 10 14 16 Inorganic salt 20 24 25 white oil 5 4 3

[0068] The main performance parameters of the "four controllable" flow regulator particles of table 2 embodiment 1-4

[0069] Examp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com