A self-healing material for oil well micro-fractures and its preparation method

A technology of micro-fractures and composite materials, applied in the field of oil drilling and cementing, can solve problems such as unfavorable industrial production, difficult preparation of microcapsules, and aging of wall materials, so as to improve the integrity of the cement sheath, avoid the risk of secondary cementing, and prevent The effect of channeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0043] On the other hand, an embodiment of the present invention provides a method for preparing the above oil well micro-fracture self-healing material, comprising the following steps:

[0044] (1) Divide water into two parts of equal quality water;

[0045] (2) dissolving nano silicon dioxide into one part of the water;

[0046] (3) dissolving sodium silicate, magnesium oxide and fumaric acid into another part of water;

[0047] (4) Mix the dispersant and fluid loss reducer with cement and stir until uniform;

[0048] (5) Mix and stir the two aqueous solutions obtained in (2) and (3) evenly; mix with the cement mixture obtained in (4) to obtain an oil well micro-fracture self-healing material.

[0049] Optionally, the preparation method of the oil well microfracture self-healing material consists of the above steps.

[0050] In the embodiment of the present invention, the mixing process refers to the oil well cement test method GBT19139-2003.

[0051] In the embodiment o...

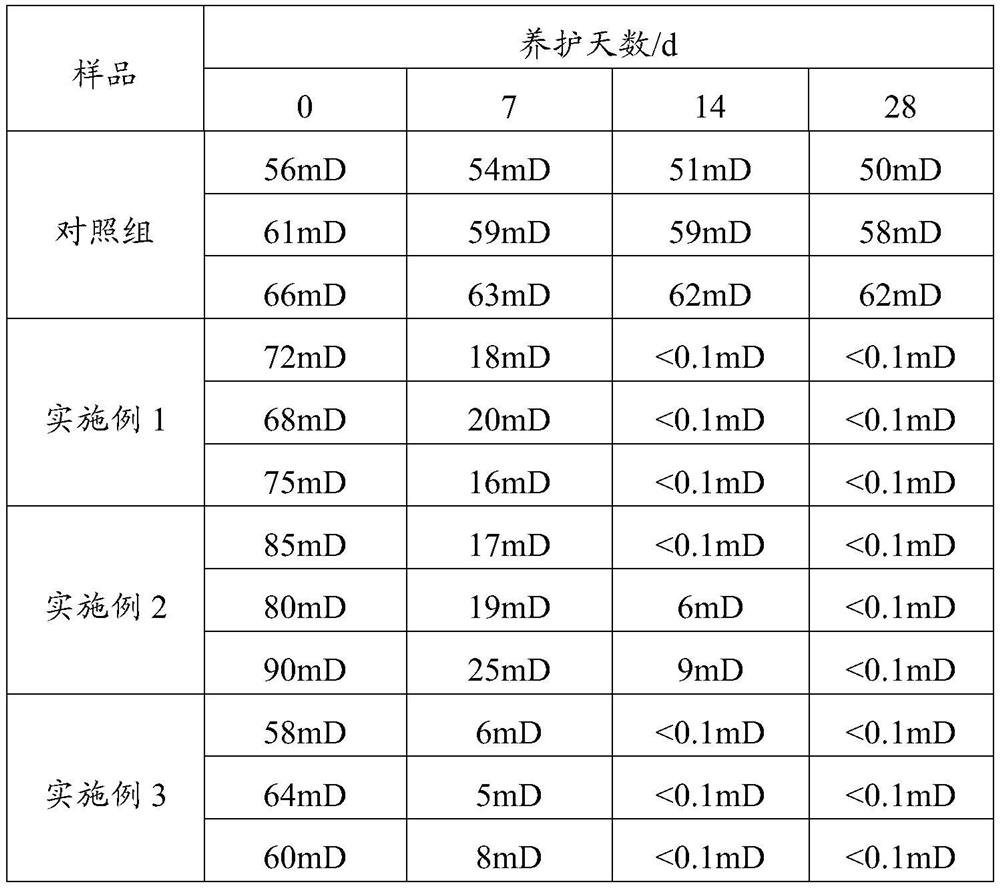

Embodiment 1

[0058] Example 1 A microcrack self-healing material was prepared according to the following steps.

[0059] 1. Weigh two parts of water, each 21g;

[0060] 2. Dissolve nano-silica with a mass of 0.5g and a particle size of 20nm in one part of the water, and stir until it is evenly dispersed;

[0061] 3. Dissolve 1g of sodium silicate, 0.2g of magnesium oxide and 0.3g of fumaric acid at a calcination temperature of 1100°C and a calcination time of 200s into another portion of water;

[0062] 4. Mix 0.2g sodium lignosulfonate and 0.8g carboxymethyl hydroxyethyl cellulose with 100g G-grade high sulfur-resistant oil well cement and stir until uniform;

[0063] 5. Mix and stir the two aqueous solutions obtained in steps 2 and 3; mix with the cement mixture obtained in step 4 to obtain self-healing composite material cement slurry, and refer to the oil well cement test method GB / T 19139-2003 for the mixing process .

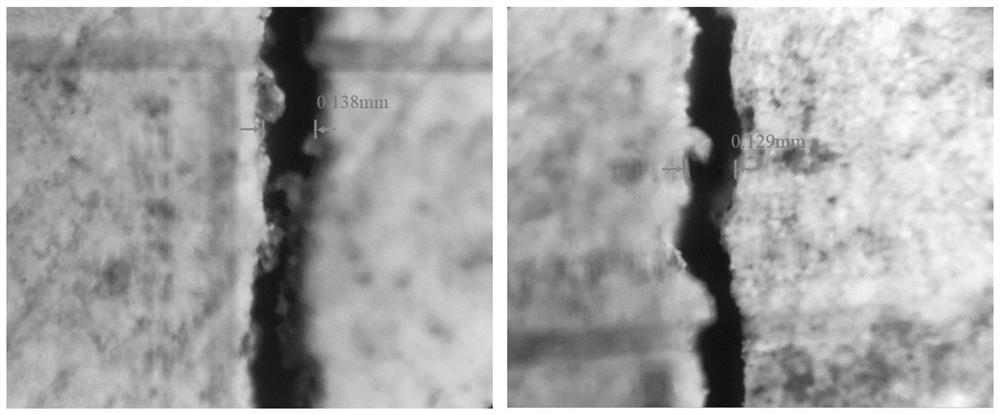

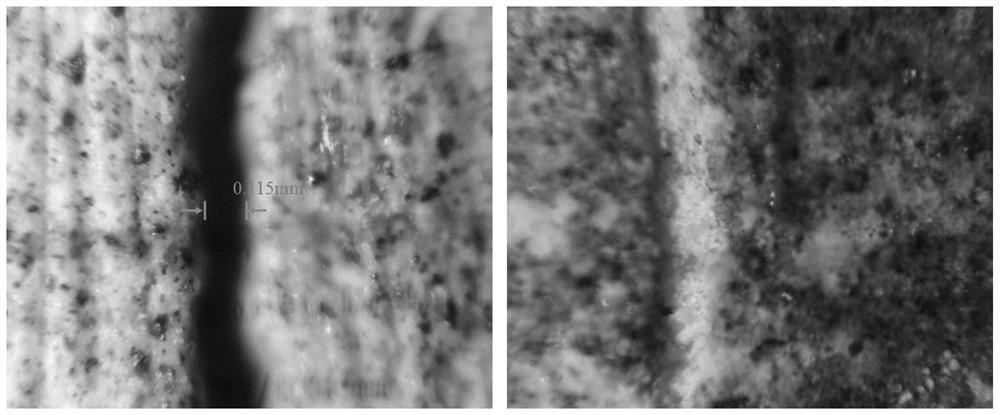

[0064] Pour the cement slurry into a cylindrical mold of 25mm×...

Embodiment 2

[0066] Example 2 A microcrack self-healing material was prepared according to the following steps.

[0067] 1. Weigh two parts of water, each 23g;

[0068] 2. Dissolve 1.5g of nano-silica with a particle size of 80nm in one part of the water, and stir until it is evenly dispersed;

[0069] 3. Dissolve 2g of sodium silicate, 0.6g of magnesium oxide and 0.9g of fumaric acid at a calcination temperature of 1200°C and a calcination time of 240s into another portion of water;

[0070] 4. Mix 0.4g sodium polystyrene sulfonate and 1.4g polyvinyl alcohol with 100g G-grade high sulfur-resistant oil well cement and stir until uniform;

[0071] 5. Mix and stir the two aqueous solutions obtained in steps 2 and 3 until uniform; mix with the cement mixture obtained in step 4 to obtain self-healing composite material cement slurry, and refer to the oil well cement test method GBT 19139-2003 for the mixing process .

[0072] Pour the cement slurry into a cylindrical mold of 25mm×50mm×25mm,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com