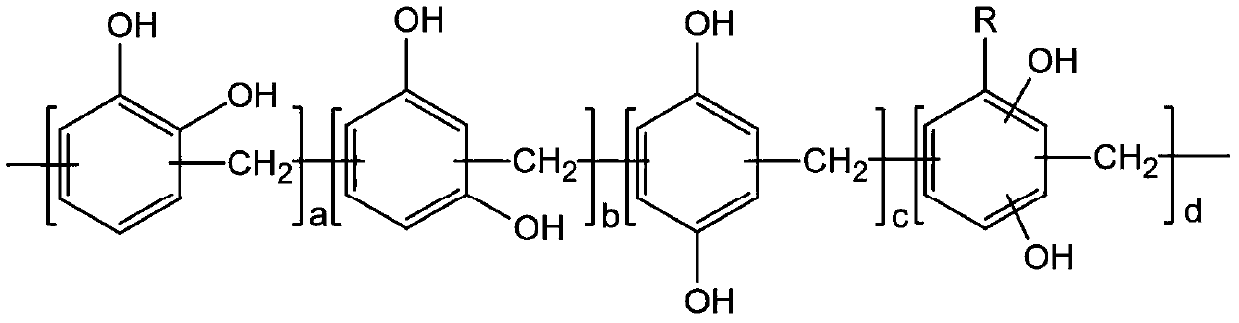

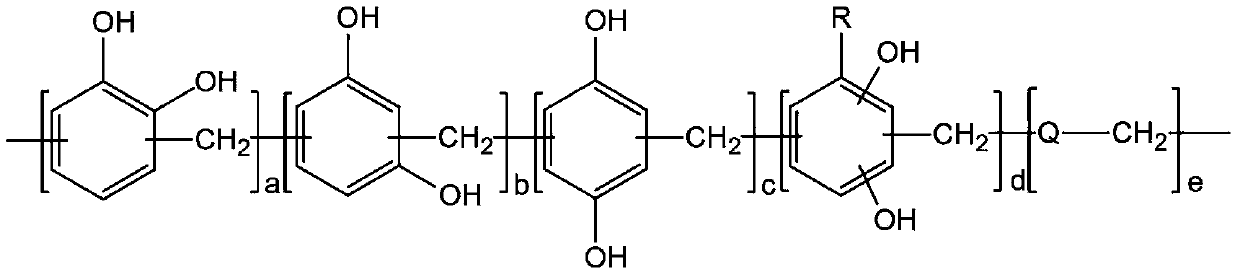

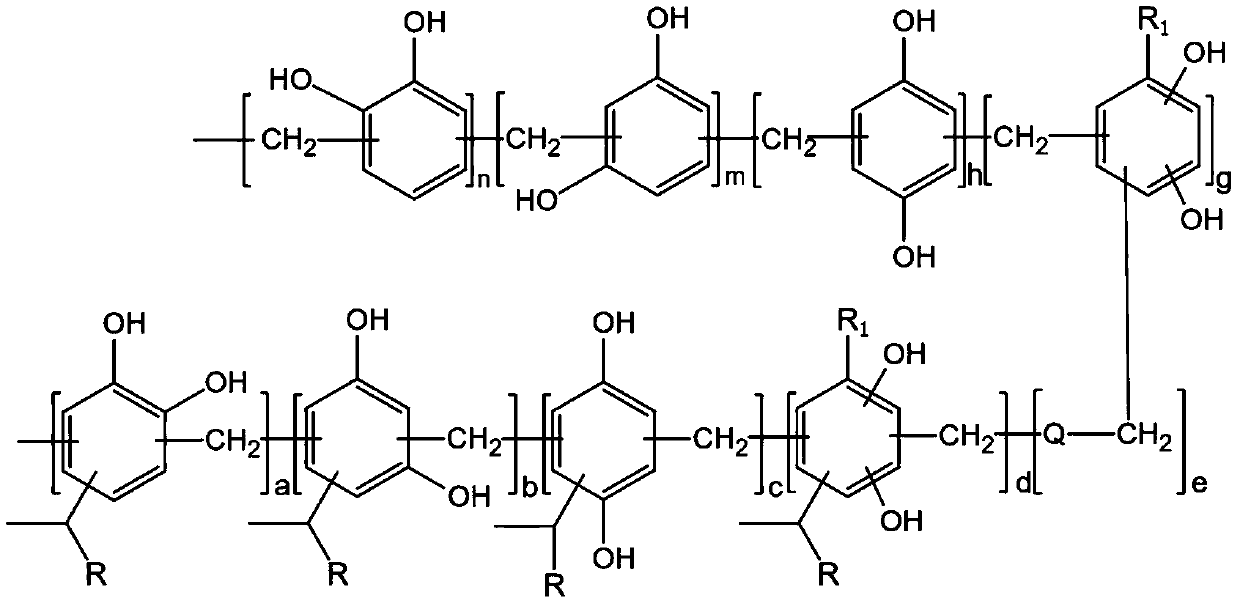

Method for preparing thermoplastic phenolic resin from benzenediol

A technology of phenolic resin and hydroquinone, applied in the direction of aldehyde/ketone condensation polymer adhesives, adhesive types, adhesives, etc., can solve the constraints of development and application, the manufacturing cost of resorcinol resin and the price of products High price, high price of raw material resorcinol, etc., to achieve the effect of reducing raw material cost and wide application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0089] Embodiment 1, the ratio of raw materials of this embodiment is as shown in Table 1.

[0090] Table 1

[0091] raw material Hydroquinone 37% formaldehyde solution p-Toluenesulfonic acid 48% Sodium Hydroxide Mass % 75.154 24.533 0.226 0.087

[0092] This embodiment includes the following steps: put the quinone mixture into the reaction kettle chemical material, add p-toluenesulfonic acid, add formaldehyde solution dropwise to the reaction kettle under the condition of 95°C to 130°C, and distill at atmospheric pressure after the dropwise addition of formaldehyde is completed After dehydration, add a terminator, vacuum dehydrate, control the temperature between 135°C and 175°C, and granulate and pack. The softening point of the phenolic resin prepared in this embodiment is 113.2° C., the weight loss by heating is 0.11%, and the ash content is 0.05%.

Embodiment 2

[0093] Embodiment 2, the ratio of raw materials of this embodiment is as shown in Table 2.

[0094] Table 2

[0095]

[0096]

[0097] This embodiment includes the following steps: put the diphenol mixture and phenol into the reaction kettle as the chemical material, add p-toluenesulfonic acid, and add the formaldehyde solution dropwise to the reaction kettle under the condition of 95°C to 130°C. After pressure distillation and dehydration, add a terminator, vacuum dehydrate, control the temperature between 135°C and 175°C, and then granulate and pack. The softening point of the phenolic resin prepared in this embodiment is 104.6°C, the weight loss by heating is 0.18%, and the ash content is 0.03%.

Embodiment 3

[0098] Embodiment 3, the ratio of raw materials of this embodiment is as shown in Table 3

[0099] table 3

[0100]

[0101] This embodiment includes the following steps: put quinone into the reaction kettle chemical material, add p-toluenesulfonic acid, and add styrene dropwise to the reaction kettle under the condition of 120°C to 135°C, after the addition of styrene is completed, the temperature is raised Mature, cool down, put in p-tert-butylphenol, add formaldehyde solution dropwise to the reaction kettle under the condition of 140°C to 155°C, after the dropwise addition of formaldehyde is completed, after atmospheric distillation and dehydration, add terminator, vacuum dehydration, The temperature is controlled between 135°C and 175°C, granulated and packaged. The softening point of the phenolic resin prepared in this embodiment is 107.4° C., the weight loss by heating is 0.08%, and the ash content is 0.02%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Softening point | aaaaa | aaaaa |

| Softening point | aaaaa | aaaaa |

| Softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com