Spherical particle surface liquid phase information identification method, system and medium

A spherical particle and information identification technology, applied in the direction of instrumentation, design optimization/simulation, calculation, etc., can solve problems such as lack of knowledge and ambiguity of the details of the gas-liquid phase behavior of the trickle bed, so as to increase the number of monitoring lines and reduce calculations Quantity and data post-processing time, and the effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

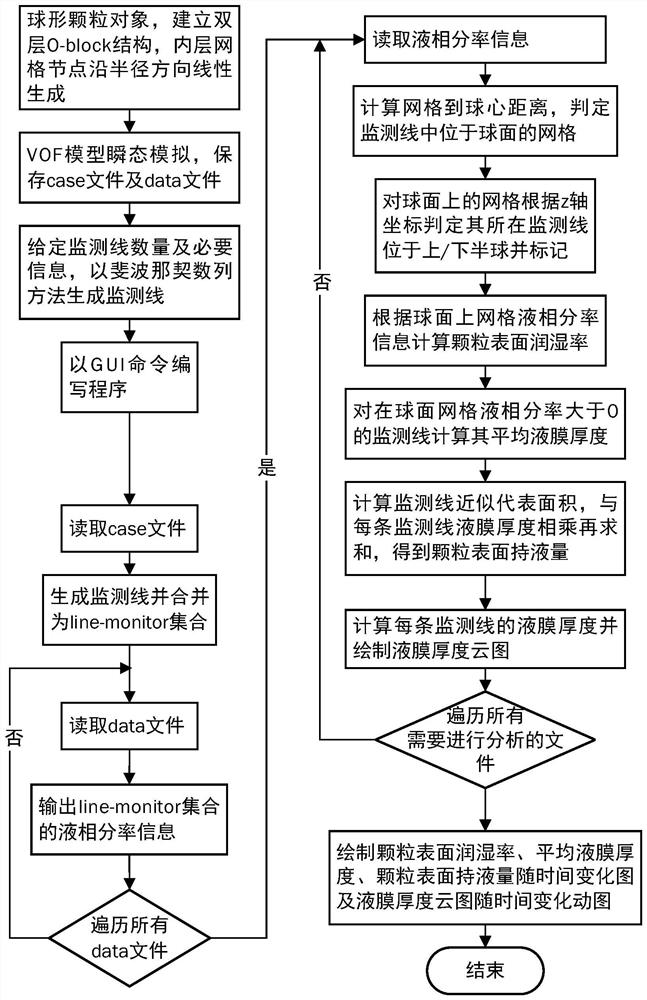

[0032] This embodiment discloses a method for identifying liquid phase information on the surface of spherical particles, such as figure 1 shown, including the following steps:

[0033] S1 builds a double-layer O-block structure grid for a single spherical particle, simulates the surface of the spherical particle based on the VOF model, and forms a file that needs to be analyzed. The files that need to be analyzed are divided into case files and data files.

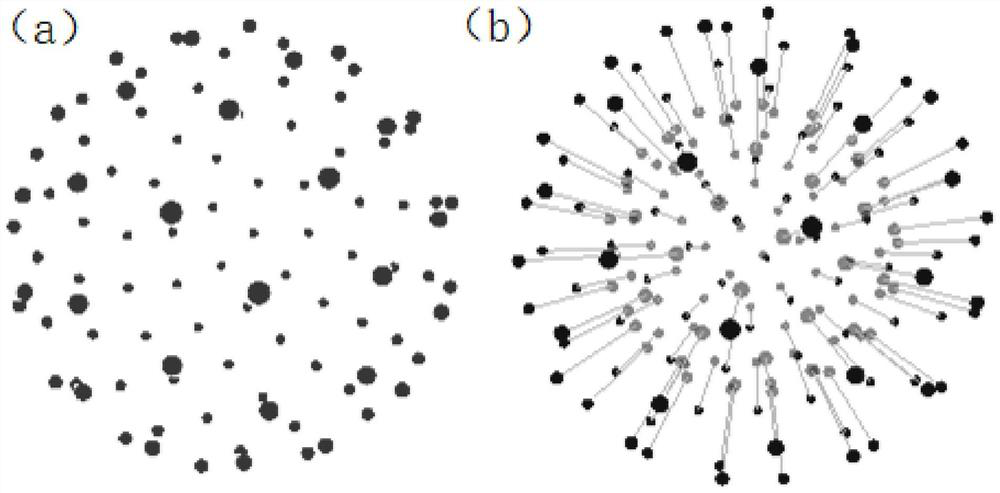

[0034] It is assumed that the simulated object in this embodiment is a standard spherical particle, and the surface of the spherical particle has a certain roughness. Determine the center coordinates of the spherical particle, the upper limit of the liquid film thickness and the number of monitoring lines (that is, the value of N). The double-layer O-block structure grid is generated linearly along the radial direction of spherical particles. In this embodiment, the center coordinates of spherical particles are set as (...

Embodiment 2

[0074] Based on the same inventive concept, this embodiment discloses a system for identifying liquid phase information on the surface of spherical particles, including:

[0075] The grid generation module is used to construct a double-layer O-block structure grid for a single spherical particle, and simulate the surface of the spherical particle based on the VOF model;

[0076] The monitoring line generation module is used to set the monitoring line on the surface of the spherical particle along the radial direction, and calculate the liquid phase fraction information of the monitoring line;

[0077] The spatial position judgment module is used to judge the grid on the spherical particle surface in each monitoring line and the hemisphere to which each monitoring line belongs according to the spatial position of the monitoring line;

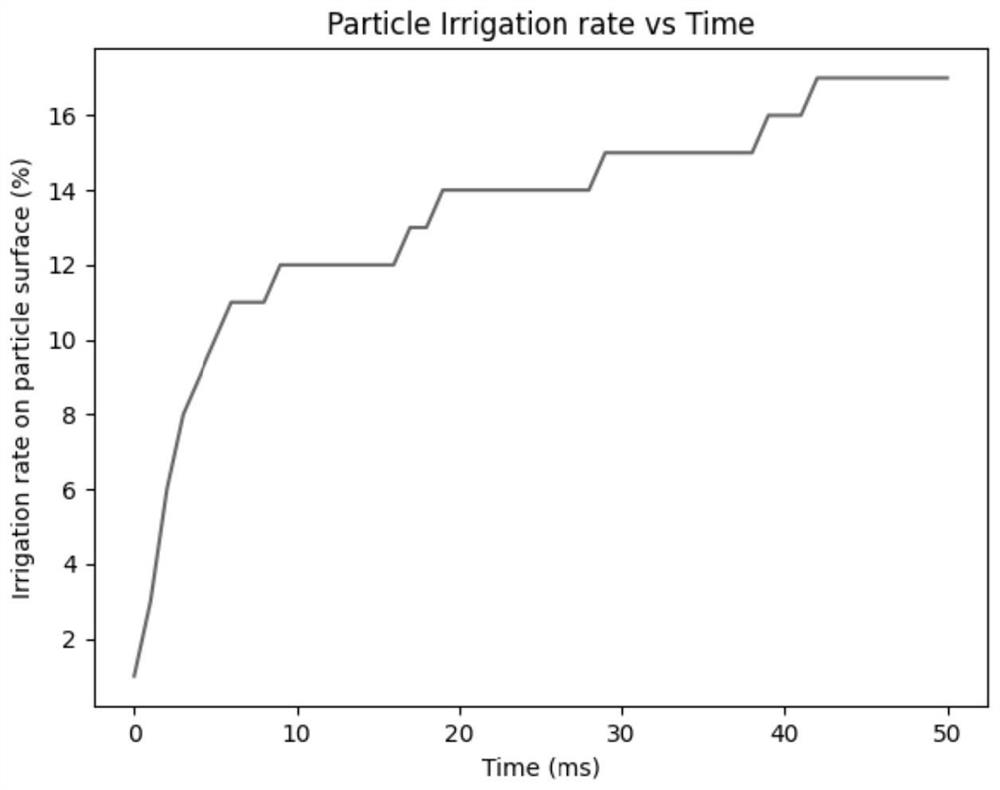

[0078] The output module is used to calculate the liquid phase wetting rate on the spherical particle surface, the average thickness of the liqu...

Embodiment 3

[0080] Based on the same inventive concept, this embodiment discloses a computer-readable storage medium that stores one or more programs, and the one or more programs include instructions that, when executed by a computing device, cause the computing device to perform the above-mentioned spherical A method for identifying liquid phase information on particle surfaces.

[0081] Those skilled in the art should understand that the embodiments of the present application may be provided as methods, systems, or computer program products. Accordingly, the present application may take the form of an entirely hardware embodiment, an entirely software embodiment, or an embodiment combining software and hardware aspects. Furthermore, the present application may take the form of a computer program product embodied on one or more computer-usable storage media (including but not limited to disk storage, CD-ROM, optical storage, etc.) having computer-usable program code embodied therein.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com