Vehicle gauge level mute range extender

A range extender and mute technology, applied in the field of range extenders, can solve problems such as poor use of range extenders, impact on vehicle applications, and vibrations, and achieve the effects of ensuring connection, reducing noise, and facilitating emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

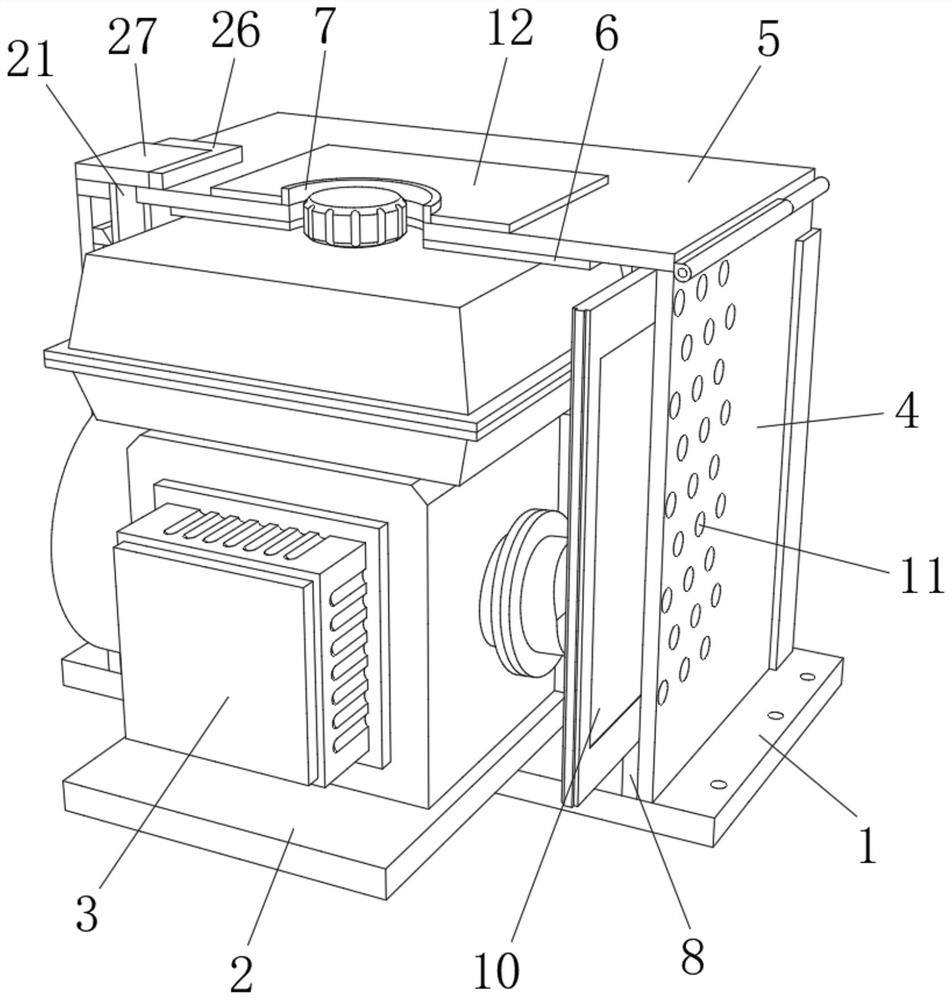

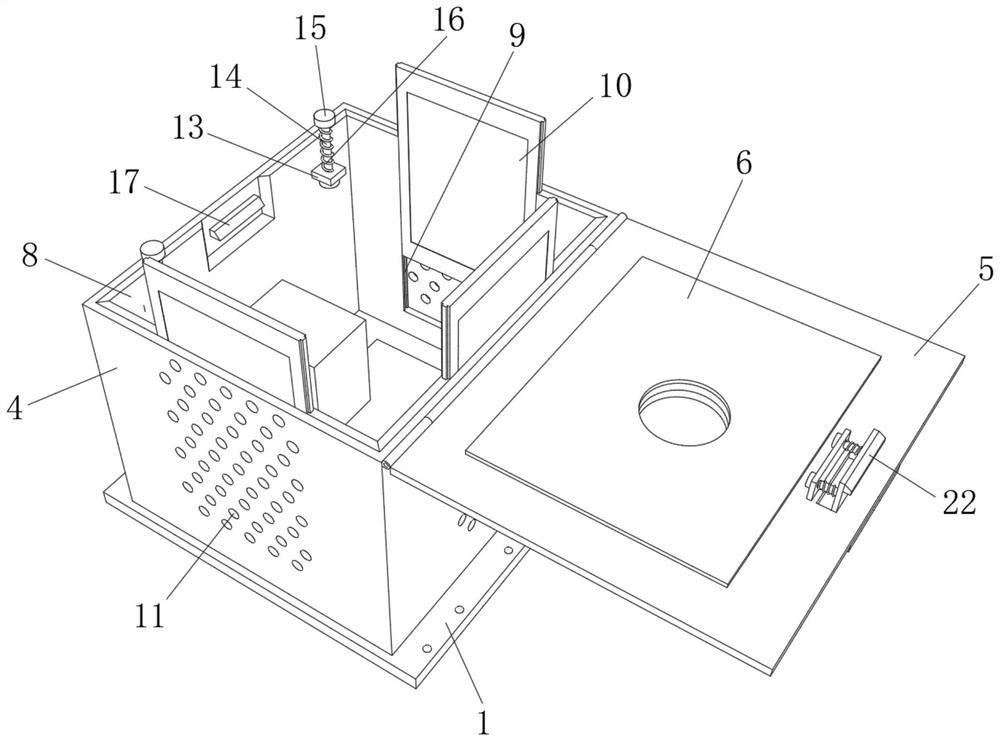

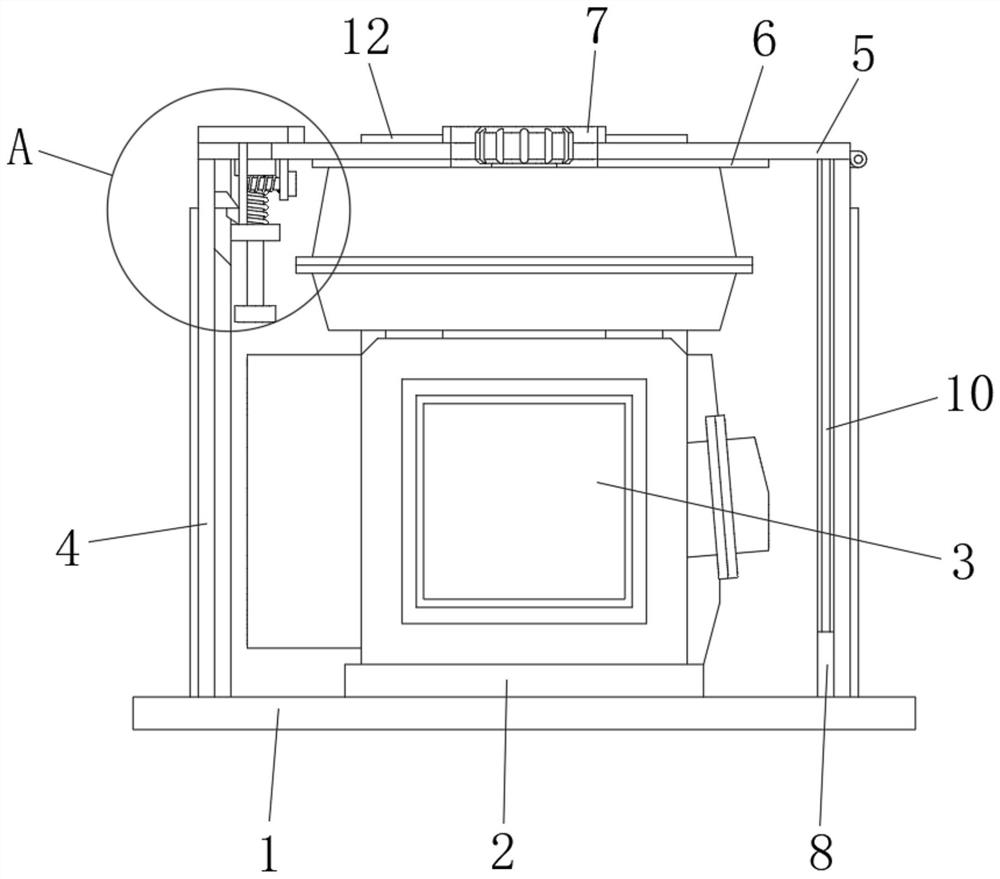

[0034] refer to Figure 1-Figure 5 , a vehicle-level silent range extender, including a base plate 1, a first rubber pad 2 is provided on the upper surface of the base plate 1, a range extender body 3 is provided on the upper surface of the first rubber pad 2, and the upper surface of the base plate 1 passes through The main frame body 4 is fixed by bolts, one side of the main frame body 4 is rotatably connected with a rotating plate 5, the bottom of the rotating plate 5 is bonded with a second rubber pad 6, and the upper surface of the rotating plate 5 is bonded with a protective ring 7, The multi-side inner walls of the main frame 4 are fixed with sound insulation panels 8 by bolts, and the design of the range extender body 3 between the first rubber pad and the second rubber pad 6 effectively prevents the range extender body 3 from collapsing during operation. It collides with the bottom plate 1, the main frame body 4 and the rotating plate 5, therefore, the generation of n...

Embodiment 2

[0038] refer to Figure 6-Figure 7 , a vehicle-level silent range extender, including a bottom frame 30 welded to the bottom of the bottom plate 1, a mounting plate 31 welded to the bottom of the bottom frame 30, a shock absorbing pad 32 bonded to the bottom of the mounting plate 31, and the bottom of the mounting plate 31 A plurality of rubber tubes 33 are plugged into the upper surface, and the rubber tubes 33 correspond to the mounting holes 29, and a plurality of L-shaped through pipes 34 are plugged into the bottom of the bottom plate 1, and the rubber tubes 33 and the mounting holes 29 are used in combination to facilitate wiring. At the same time, the discharge pipe of the exhaust gas produced by the range extender body 3 passes through the L-shaped through pipe 34 to facilitate its integration and induction. The L-shaped through pipe 34 passes through the bottom frame 30 .

[0039] The working principle of this embodiment: when in use, the rubber cylinder 33 and the in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com