Feeding system capable of achieving adjustment in automatic production and feeding method

A feeding system and material leakage technology, which is applied in the direction of conveyor objects, transportation and packaging, conveyors, etc., can solve the problems of material falling, adjusting the speed of material falling, inconvenience, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

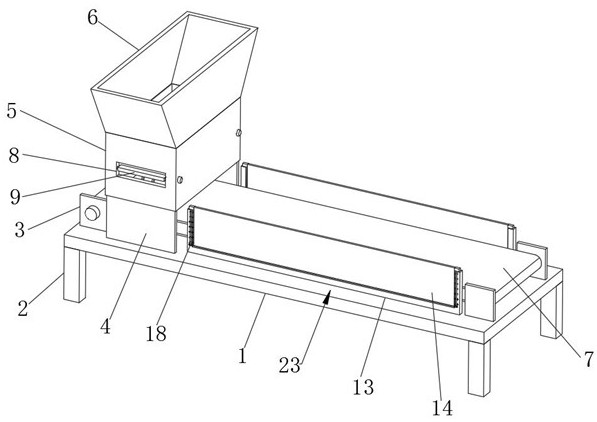

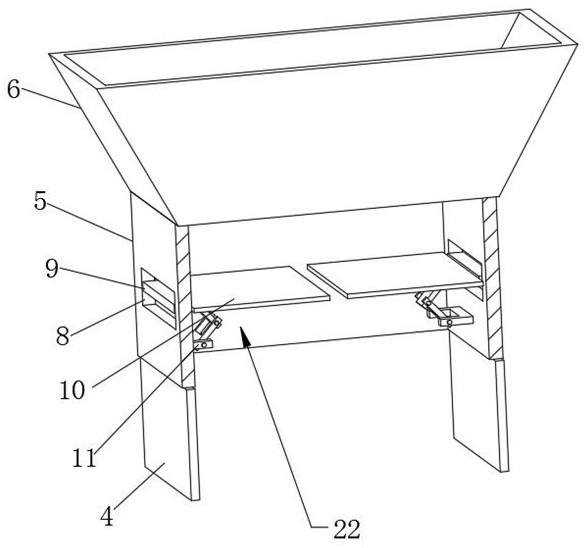

[0027] see Figure 1-5 , the present invention provides a technical solution: an adjustable feeding system in automated production, including a base plate 1, support rods 2 are installed on the bottom surface of the base plate 1 near the four corners, and connecting plates are installed on the upper surface of the base plate 1 near the two edges 4. A leaking material frame 5 is installed on the upper surface of the connecting plate 4. An adjustment mechanism 22 is arranged inside the leaking material frame 5. A funnel 6 is installed on the upper surface of the leaking material frame 5. The upper surface of the bottom plate 1 near both edges is provided with anti-dropping devices. agency23.

[0028] see figure 1 , Figure 4 and Figure 5 , the anti-drop mechanism 23 includes a connecting plate 13, the outer surface of the connecting plate 13 is provided with movable slots, the inner walls of the two movable grooves are provided with slots 15, and the inside of the slots 15 i...

Embodiment 2

[0033] see Figure 1-5 , the present invention provides a technical solution: an adjustable feeding system in automatic production, including a base plate 1, the bottom surface of the base plate 1 is equipped with support rods 2 near the four corners, and the upper end surface of the base plate 1 is located near the two edges. An adapter plate 4 is installed, and a leakage frame 5 is installed on the upper surface of the engagement plate 4. An adjustment mechanism 22 is arranged inside the leakage frame 5. A funnel 6 is installed on the upper surface of the leakage frame 5. The bottom plate 1 An anti-drop mechanism 23 is provided on the upper surface near the two edges.

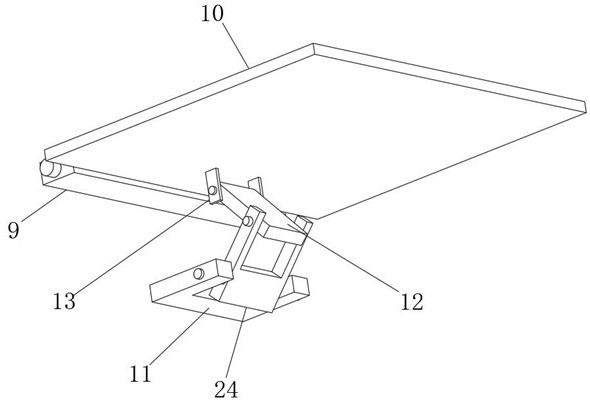

[0034] see Figure 2-3 , the adjustment mechanism 22 includes a transverse groove 8, a movable plate 9 is arranged inside the transverse groove 8, a short shaft is installed between the two sides of the movable plate 9 and the inner wall of the transverse groove 8, and the outer surface of the leakage frame 5 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com