Filter cartridge core suitable for cheese dyeing

A filter cartridge and package yarn technology, applied in the field of package yarn dyeing, can solve problems such as defects or color pattern weaving and influence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

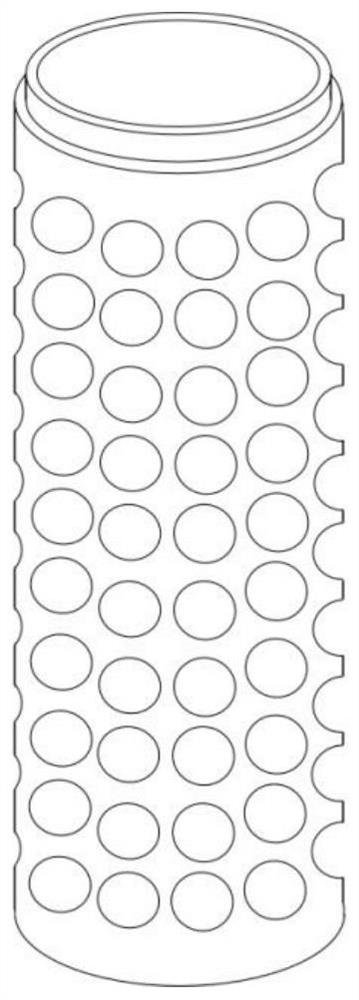

[0021] The core material of a filter core suitable for cheese dyeing in this embodiment is PET material.

[0022] First, follow the figure 1 The pouring mold required to make the filter cartridge.

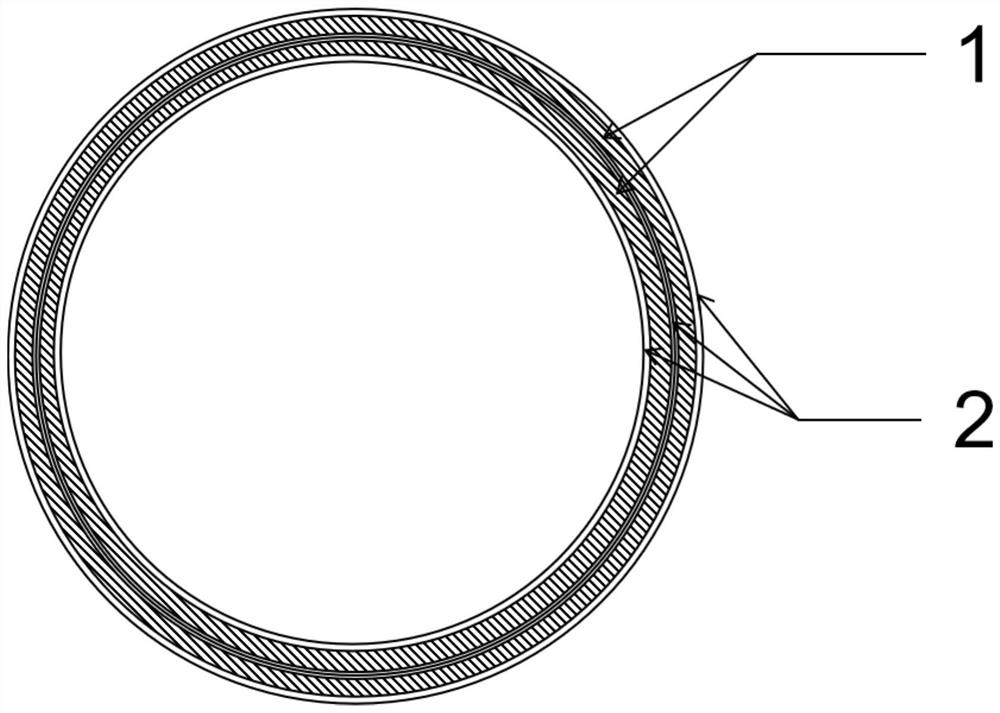

[0023] Add two layers of 1000-mesh stainless steel filter screen as filter screen 2 in the pouring cavity of the casting mold, and then pour PET raw material into the mold, solidify and form, and become the filter cartridge core.

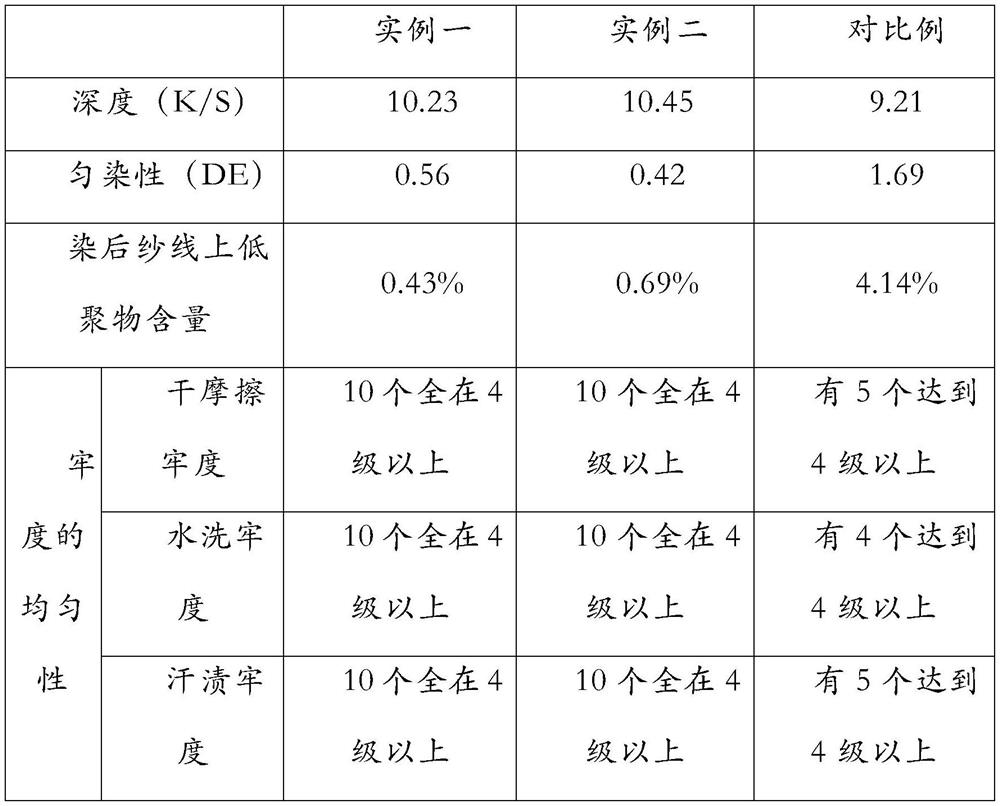

[0024] Carry out dyeing experiment of 25kg polyester bobbin yarn after forming.

Embodiment 2

[0026] The material of the core 1 of a filter core suitable for cheese dyeing in this embodiment is stainless steel.

[0027] according to figure 1 A stainless steel material with a thickness of δ2mm is selected for punching, bending, and welding to make the barrel core 1 .

[0028] 800 mesh stainless steel screens are welded inside and outside the cylinder core 1 as the screen 2.

[0029] Carry out 25kg polyester bobbin dyeing experiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com