Sterile liquid food production device for digestive tract tumor patients to eat

A technology for digestive tract tumors and production equipment, which is applied in the field of aseptic liquid food production equipment, can solve the problems of liquid food waste and easy deviation, and achieve the effect of avoiding waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

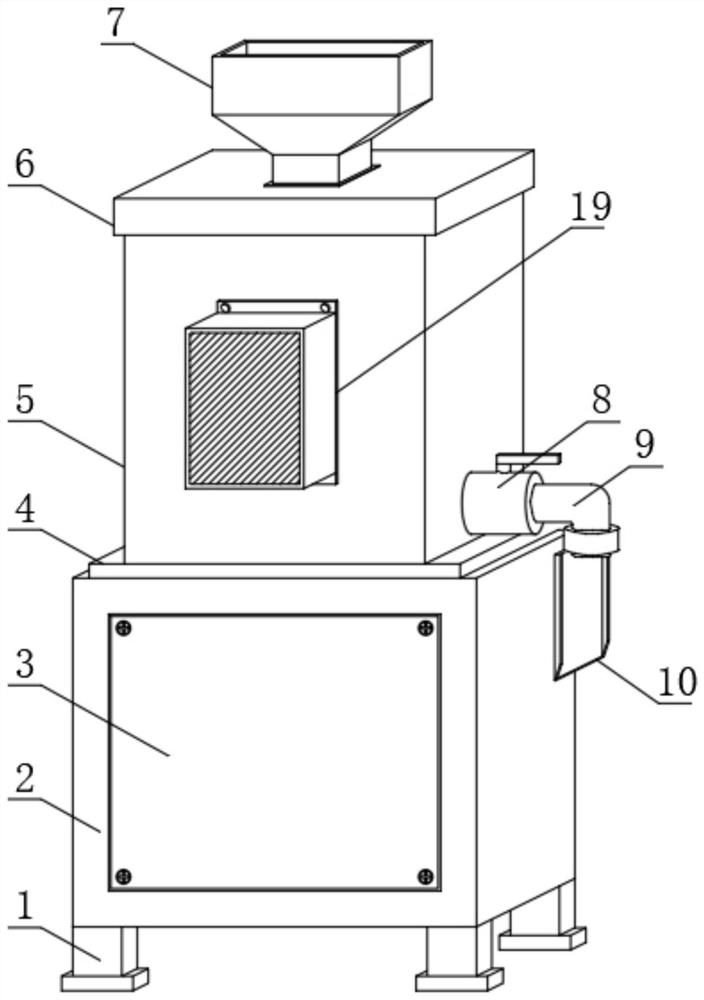

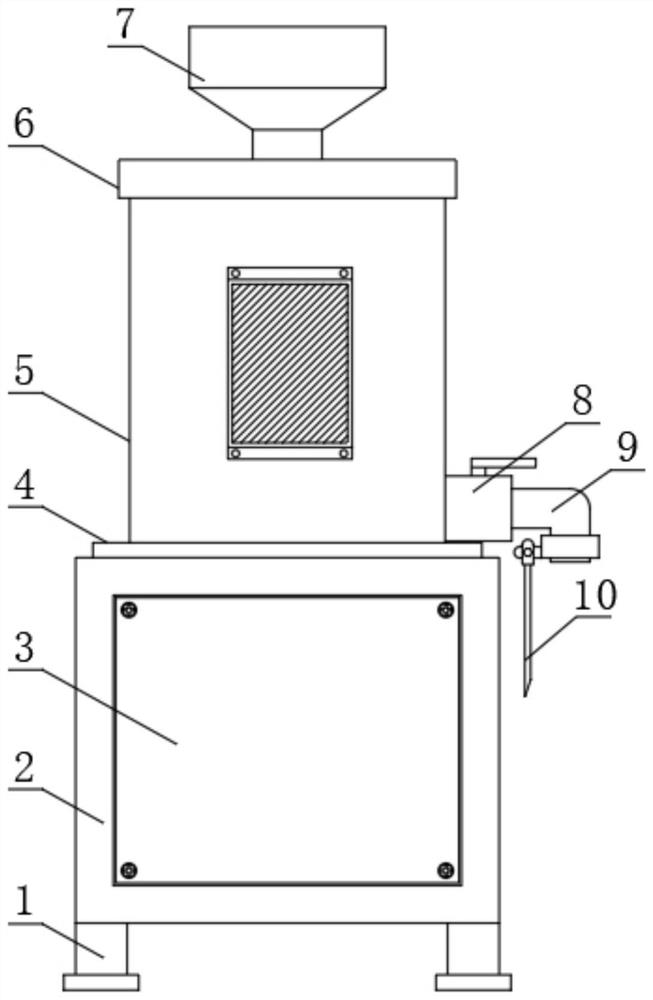

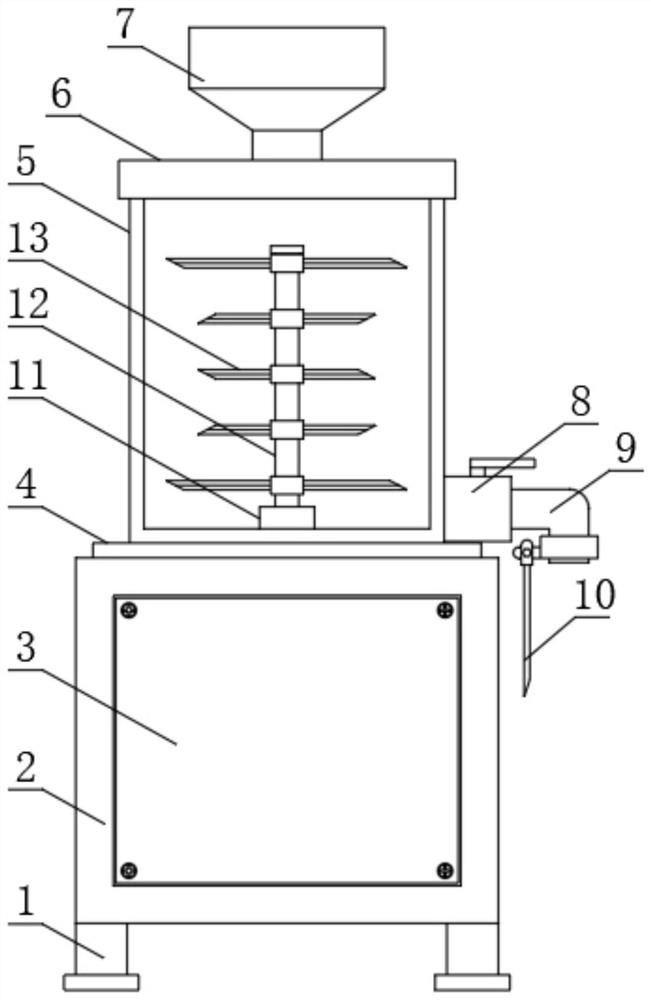

[0030]see figure 1 , figure 2 , Figure 5 , Figure 6 , the present invention provides a kind of technical scheme: a kind of aseptic liquid food production device that is used for digestive tract tumor patient to eat, comprises power cabinet 2 and liquid food production tank 5, and liquid food production tank 5 is installed on the upper end of power cabinet 2, and liquid food production tank 5 is provided with a vibrator 19 at the front end, and the vibrator 19 is electrically connected to an external power supply. The vibrator 19 includes a mounting plate 20, a housing 21, a mounting frame 22 and a vibrating motor 23. The upper end of the housing 21 is fixedly provided with a mounting plate 20 , the inside of the housing 21 is provided with a vibrating motor 23, the vibrating motor 23 and the housing 21 are fixedly connected through the mounting frame 22, and the vibrator 19 is installed and fixed at the front end of the liquid food production tank 5 through the mounting p...

Embodiment 2

[0032] see figure 1 , figure 2 , image 3 , Figure 4 , the present invention provides a technical solution: an aseptic liquid food production device for patients with digestive tract tumors, the discharge guide device 10 includes a discharge guide plate 14, an angle locking bolt 15, an angle connecting rod 16, a U-shaped angle Sleeve 17 and detachable fixed sleeve 18, detachable fixed sleeve 18 is sleeved on L-shaped discharge pipe 9 near the circular exterior of the lower end, and detachable fixed sleeve 18 rear end outer wall is provided with angle connecting rod 16, and angle connecting rod 16 is close to There is a U-shaped corner sleeve 17 with an upward opening on the outside of the rear side. The U-shaped corner sleeve 17 and the angle connecting rod 16 are rotatably connected by the angle locking bolt 15. The lower end of the U-shaped angle sleeve 17 is connected with a discharge guide plate 14, and the angle is locked. After the bolt 15 is unscrewed, the U-shaped...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com