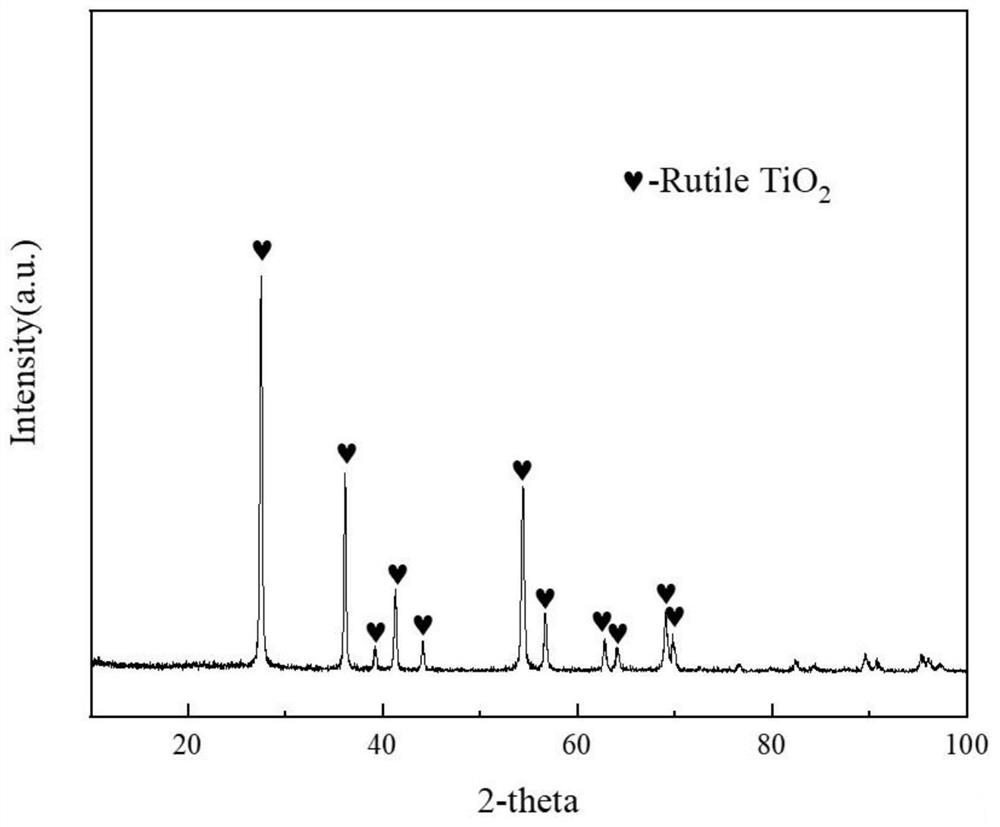

Method for preparing nano rutile from sub-molten salt modified low-grade titanium slag

A nano-rutile, low-grade titanium technology, applied in nanotechnology, nanotechnology, chemical instruments and methods, etc., can solve the problem of high element content, achieve environmental protection, good promotion and application prospects, and achieve the effect of large-scale production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to make the purpose, technical solutions and advantages of the embodiments of the present invention clearer, the technical solutions in the embodiments of the present invention will be clearly and completely described below. Those who do not indicate the specific conditions in the examples are carried out according to the conventional conditions or the conditions suggested by the manufacturer. The reagents or instruments used were not indicated by the manufacturer, and they were all conventional products that could be purchased from the market.

[0031] An artificial rutile and a method for producing artificial rutile by using titanium-containing blast furnace slag are described in detail below.

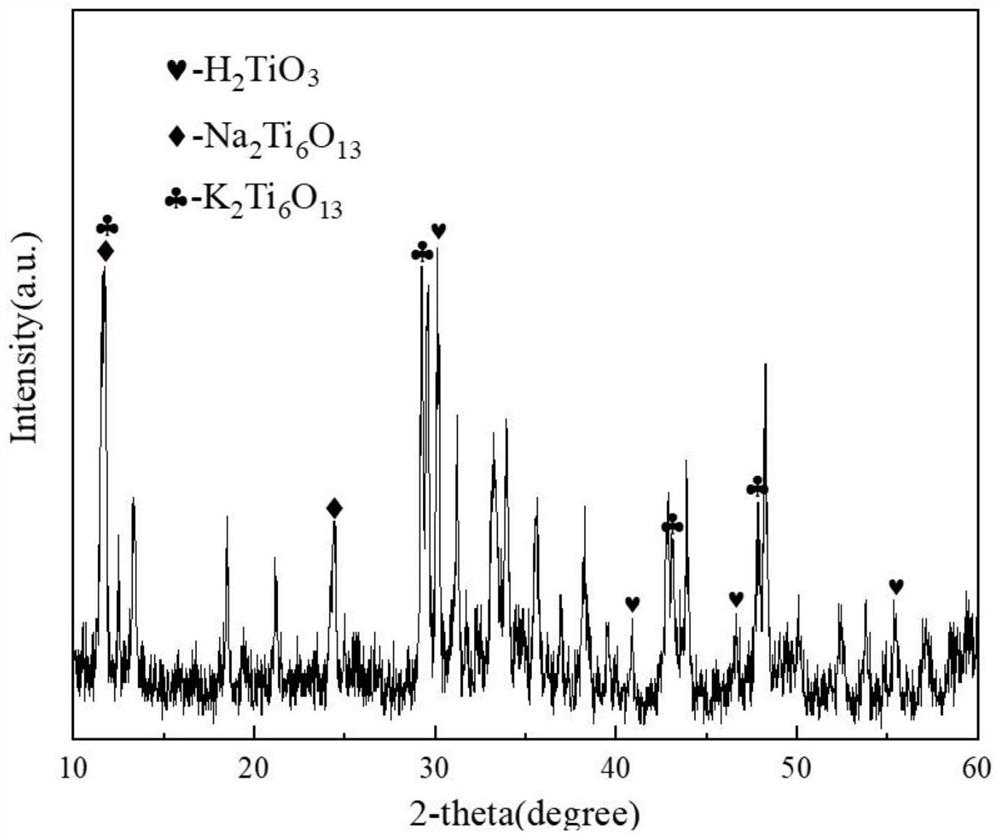

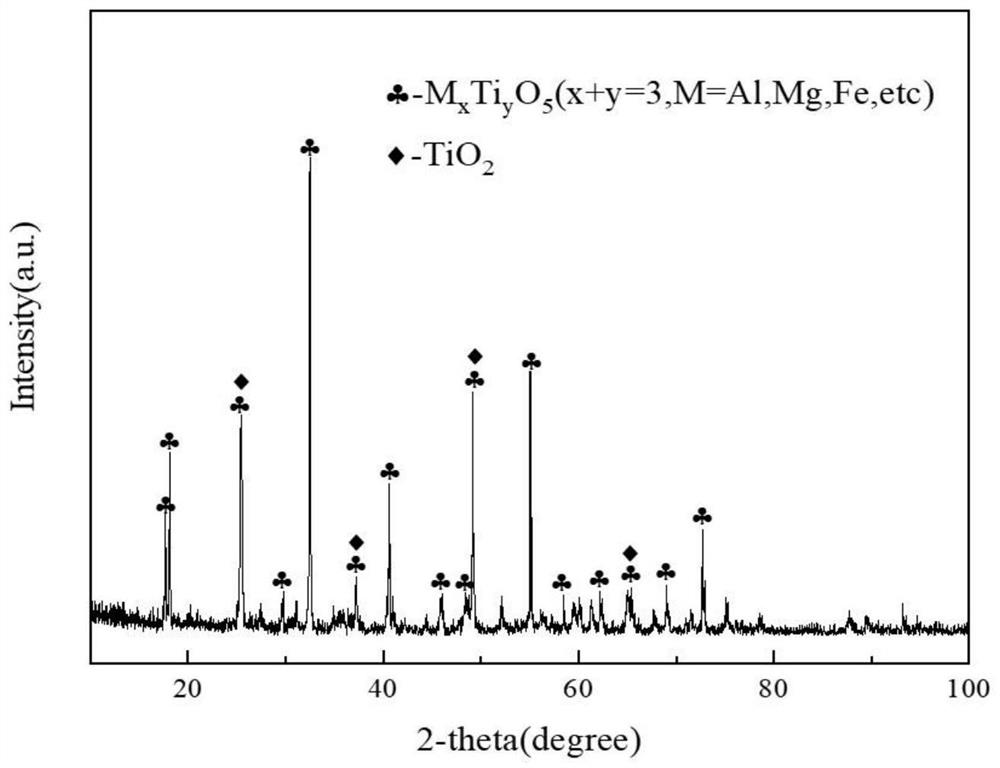

[0032] A method for preparing nanometer rutile by modifying low-grade titanium slag with sub-molten salt is provided, and the method includes the following steps:

[0033] a. Mix NaOH-KOH (molar ratio 1:1), deionized water and titanium slag into the muffle furnace ac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com