Preparation method of molybdenum-containing radioactive waste glass ceramic solidified body

A technology of radioactive waste and glass ceramics, which is applied in the solidification treatment of radioactive waste, the treatment and disposal of radioactive waste, and can solve the problems of the overall solidified amount of molybdenum yellow relative to the adverse effect on the stability of the solidified body, and achieve good treatment and disposal effects and practicability Strong, simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A method for preparing a molybdenum-containing radioactive waste glass-ceramic solidified body, the steps are:

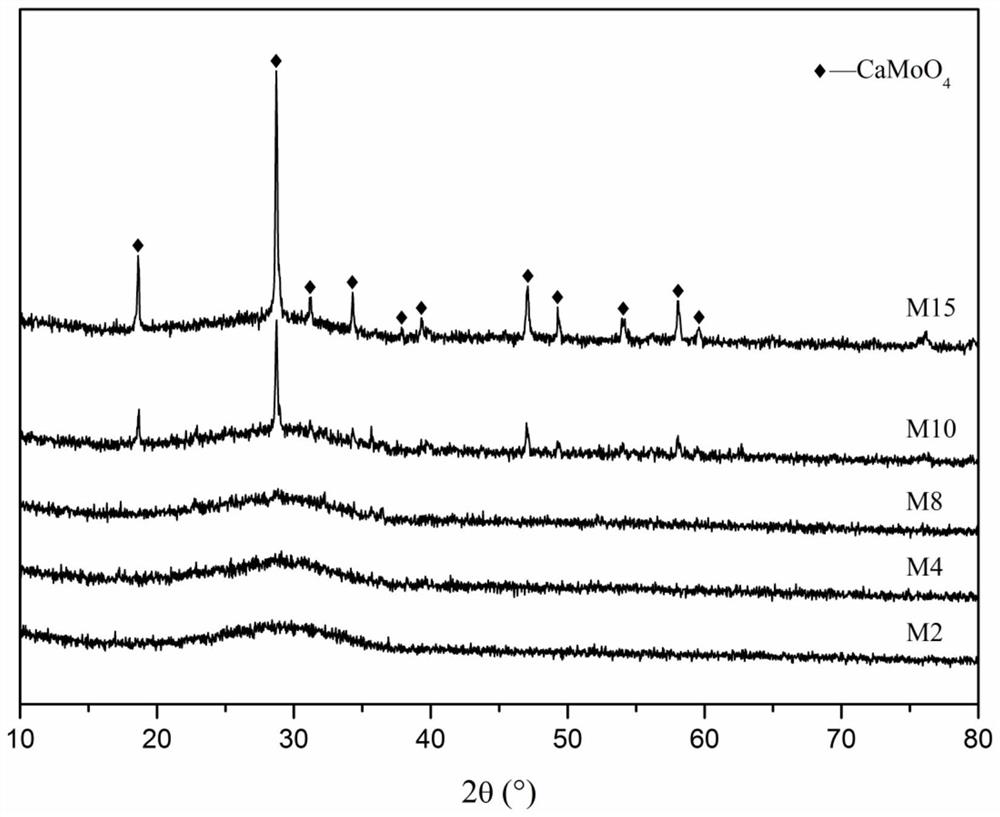

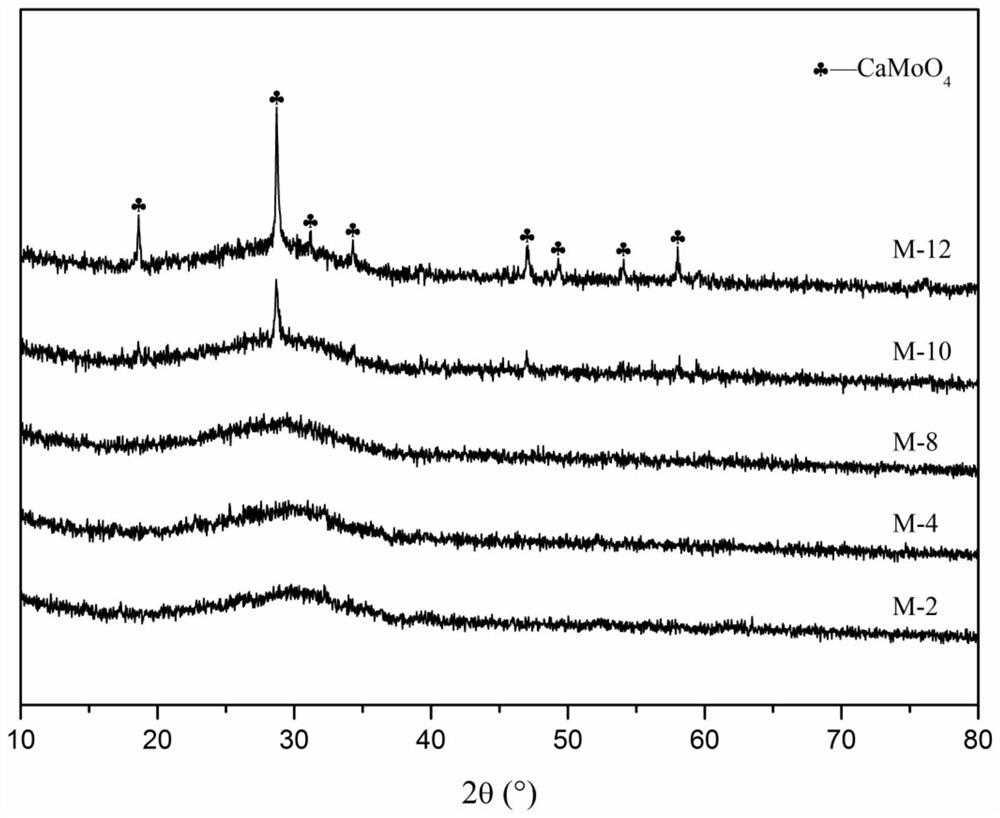

[0031] a. According to the mass percentage of pyroxene 98% and simulated radioactive waste 2%, weigh 29.4g of raw pyroxene, MoO 3 0.6g, the pyroxene and the simulated radioactive waste are ball-milled and mixed uniformly to obtain a mixture; the simulated molybdenum-containing radioactive waste is MoO 3 ;

[0032] b. Heat the mixture at a rate of 10°C / min to 1400°C for heat preservation and melting (heating and melting in a high-temperature box furnace) for 3 hours to obtain a liquid melt, and cast the liquid melt on a preheated mold or graphite plate Then (quickly) transfer the glass block to another annealing furnace for annealing. The annealing process is: keep warm in the annealing furnace at 600°C for 2 hours, and drop to room temperature with the furnace (that is, cooling), that is Prepare molybdenum-containing radioactive waste vitrified body;

[00...

Embodiment 2

[0035] A method for preparing a molybdenum-containing radioactive waste glass-ceramic solidified body, the steps are:

[0036] a. According to the mass percentage of 96% pyroxene and 4% simulated radioactive waste, weigh 28.8g raw pyroxene, MoO 3 1.2g, the pyroxene and the simulated radioactive waste are ball-milled and mixed uniformly to obtain a mixture; the simulated molybdenum-containing radioactive waste is MoO 3 ;

[0037] b. Heat the mixture at a rate of 10°C / min to 1400°C for heat preservation and melting (heating and melting in a high-temperature box furnace) for 3 hours to obtain a liquid melt, and cast the liquid melt on a preheated mold or graphite plate Then (quickly) transfer the glass block to another annealing furnace for annealing. The annealing process is: keep warm in the annealing furnace at 600°C for 2 hours, and drop to room temperature with the furnace (that is, cooling), that is Prepare molybdenum-containing radioactive waste vitrified body;

[0038]...

Embodiment 3

[0040] A method for preparing a molybdenum-containing radioactive waste glass-ceramic solidified body, the steps are:

[0041] a. According to the mass percentage of 92% pyroxene and 8% simulated radioactive waste, weigh 27.6g raw pyroxene, MoO 3 2.4g, the pyroxene and simulated radioactive waste are ball-milled and mixed uniformly to obtain a mixture; the simulated molybdenum-containing radioactive waste is MoO 3 ;

[0042] b. Heat the mixture at a rate of 10°C / min to 1400°C for heat preservation and melting (heating and melting in a high-temperature box furnace) for 3 hours to obtain a liquid melt, and cast the liquid melt on a preheated mold or graphite plate Then (quickly) transfer the glass block to another annealing furnace for annealing. The annealing process is: keep warm in the annealing furnace at 600°C for 2 hours, and drop to room temperature with the furnace (that is, cooling), that is Prepare molybdenum-containing radioactive waste vitrified body;

[0043] The...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com